A carbon fiber controllable laser ultra-high temperature graphitization device

A carbon fiber, ultra-high temperature technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of high energy consumption, difficult to achieve ultra-high temperature graphitization above 2500 ° C, and short life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

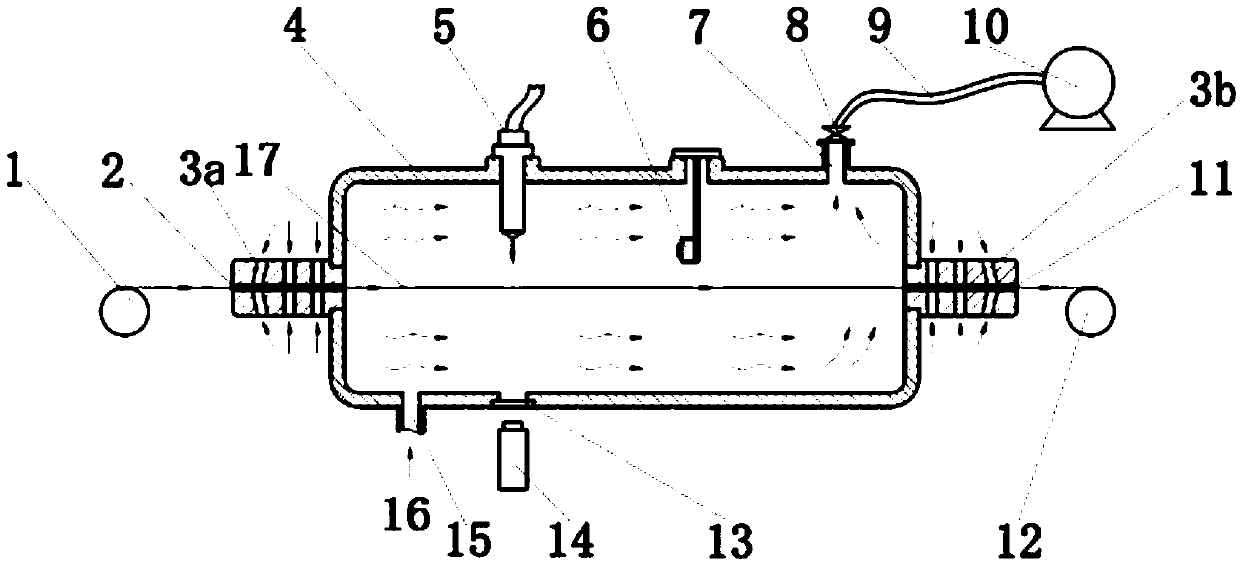

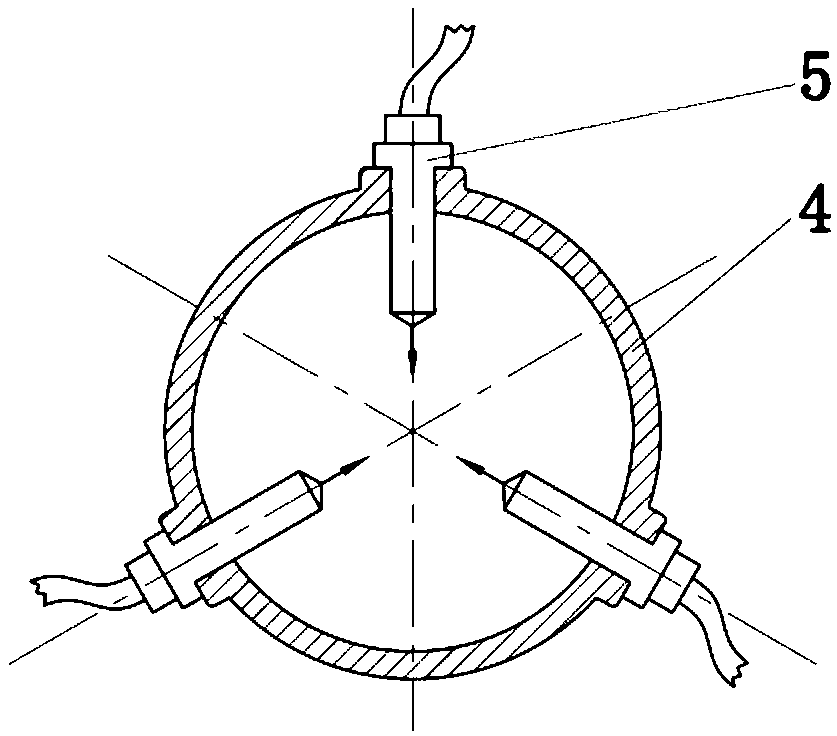

[0013] A carbon fiber controllable laser type ultra-high temperature graphitization method and device of the present invention, such as figure 1 As shown, it mainly includes a wire feeding device 1, a sealing device, a furnace body 4, a controllable laser, an observation camera 6, an air valve 8, a gas pipe 9, a micro air pump 10, a quartz glass window 13, an ultra-high temperature infrared thermometer 14, Argon purifier and wire receiving device 12. The sealing device is located at the entrance and exit of the carbon fiber 17 on the side wall of the furnace body. The sealing device includes an inlet seal 3a and an outlet seal 3b. The inlet seal 3a and the outlet seal 3b have an argon gas injection port and the carbon fiber 17 passes through, and the furnace is blocked by the pressure of argon gas. The air flow between the body and the outside world creates an oxygen-free environment for the furnace body, and a strict inert gas protection environment is formed in the furnace. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com