Preparation method of impact-resistant UPVC cold-bending electrical bushing

An electrical casing, impact-resistant technology, applied in tubular articles, applications, household appliances, etc., can solve the problems of insufficient shaping effect, low cooling and shaping efficiency, poor impact resistance, etc., to improve hardness and heat resistance, The effect of good thermodynamic compatibility and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

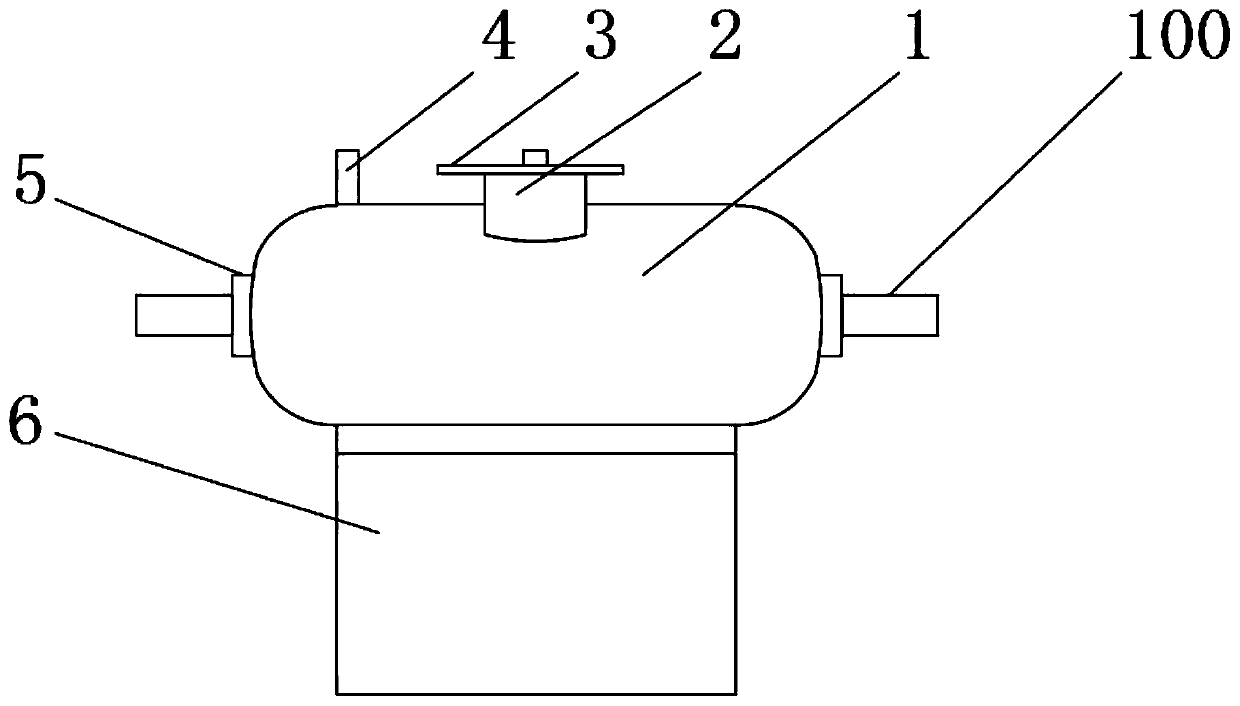

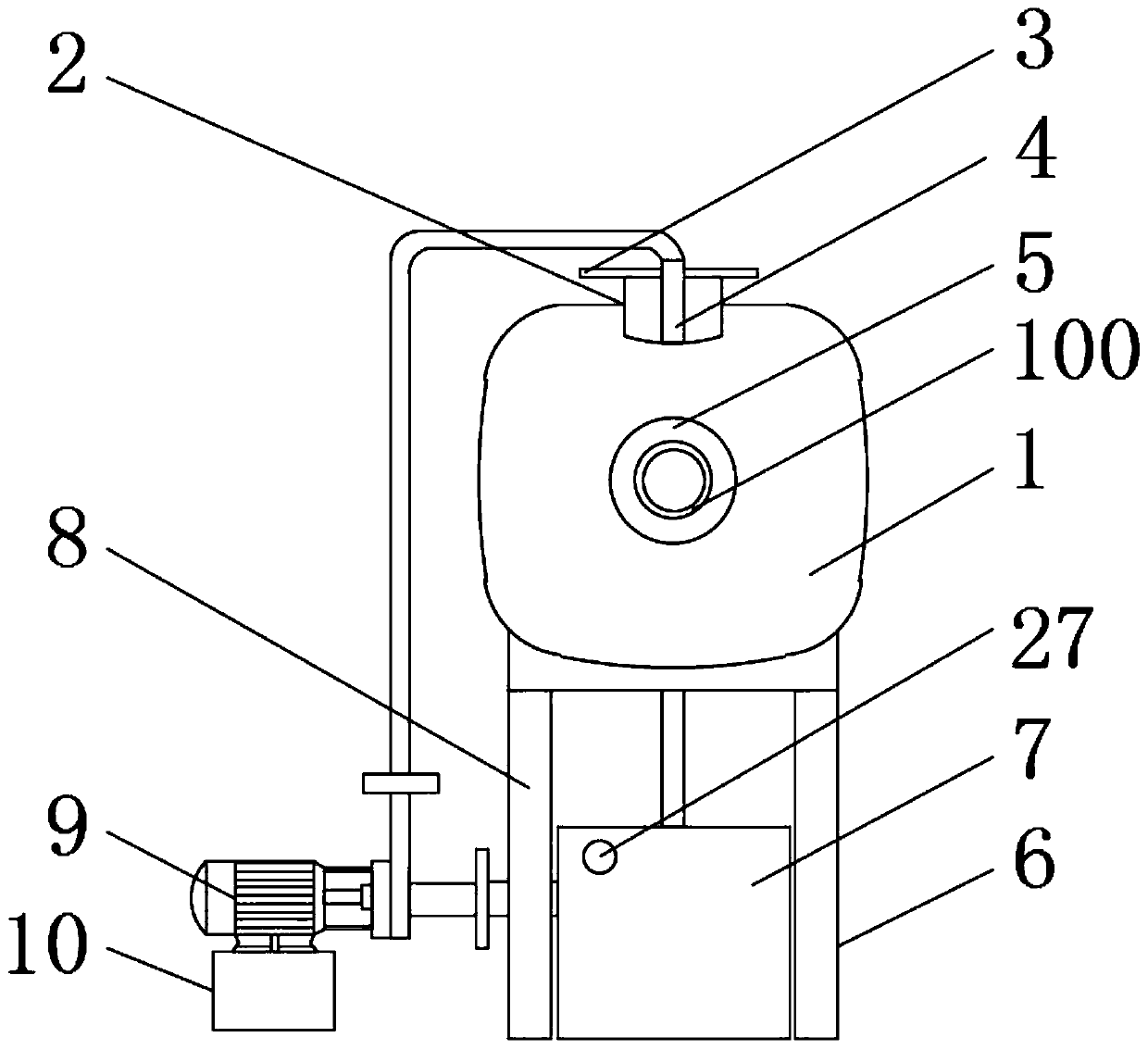

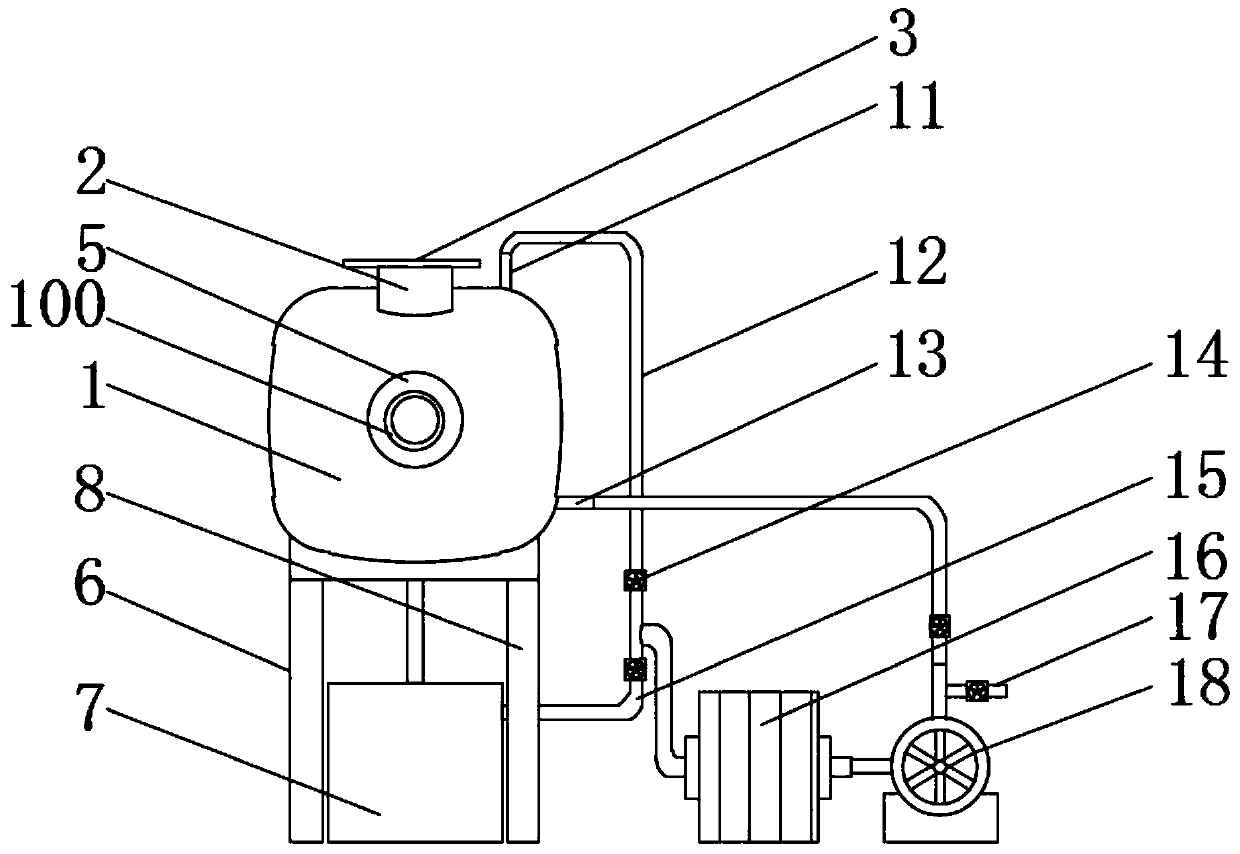

[0032] see Figure 1-4 As shown, this embodiment is a preparation method of an impact-resistant UPVC cold-formed electrical bushing. The impact-resistant UPVC cold-formed electrical bushing includes the following components by weight: 90 parts of UPVC resin, 10 parts of light calcium carbonate, 5.5 parts of composite stabilizer, 4 parts of titanium dioxide, 3 parts of impact modifier, 1 part of paraffin, 0.8 part of stearic acid, 0.6 part of chlorinated polyethylene, 0.05 part of weather resistance additive, and 0.01 part of processing modifier;

[0033] The impact-resistant UPVC cold-formed electrical casing includes the following steps:

[0034] Step 1: Weighing raw materials: Weighing raw materials according to the above components by weight;

[0035] Step 2: Prepare the mixture: put each raw material into the high-speed mixer through the feed port and mix and stir to obtain the mixture;

[0036] Step 3: Prepare the blank: add the mixture to the twin-screw extruder, and h...

Embodiment 2

[0045] see Figure 1-4 As shown, this embodiment is a preparation method of an impact-resistant UPVC cold-formed electrical bushing. The impact-resistant UPVC cold-formed electrical bushing includes the following components by weight: 100 parts of UPVC resin, 15 parts of light calcium carbonate, Composite stabilizer 8.2 parts, titanium dioxide 7 parts, impact modifier 5 parts, paraffin wax 3 parts, stearic acid 1.9 parts, chlorinated polyethylene 1.7 parts, weather resistance additive 0.25 parts, processing modifier 0.15 parts;

[0046] The impact-resistant UPVC cold-formed electrical casing includes the following steps:

[0047] Step 1: Weighing raw materials: Weighing raw materials according to the above components by weight;

[0048] Step 2: Prepare the mixture: put each raw material into the high-speed mixer through the feed port and mix and stir to obtain the mixture;

[0049] Step 3: Prepare the blank: add the mixture to the twin-screw extruder, and heat and melt the m...

Embodiment 3

[0058] see Figure 1-4 As shown, this embodiment is a preparation method of an impact-resistant UPVC cold-formed electrical bushing. The impact-resistant UPVC cold-formed electrical bushing includes the following components by weight: 110 parts of UPVC resin, 20 parts of light calcium carbonate, 11.5 parts of composite stabilizer, 10 parts of titanium dioxide, 7 parts of impact modifier, 5 parts of paraffin, 3 parts of stearic acid, 2.8 parts of chlorinated polyethylene, 0.5 parts of weather resistance additives, and 0.3 parts of processing modifier;

[0059] The impact-resistant UPVC cold-formed electrical casing includes the following steps:

[0060] Step 1: Weighing raw materials: Weighing raw materials according to the above components by weight;

[0061] Step 2: Prepare the mixture: put each raw material into the high-speed mixer through the feed port and mix and stir to obtain the mixture;

[0062] Step 3: Prepare the blank: add the mixture to the twin-screw extruder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com