PVC protective lining and its construction and construction leak detection method

A construction method and lining technology, applied in wellbore lining, marine engineering, protection devices, etc., can solve the problems of lack of sealing, waste of resources, unverifiable, etc., and achieve reliable and lasting combination effect and ensure the effect of engineering quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

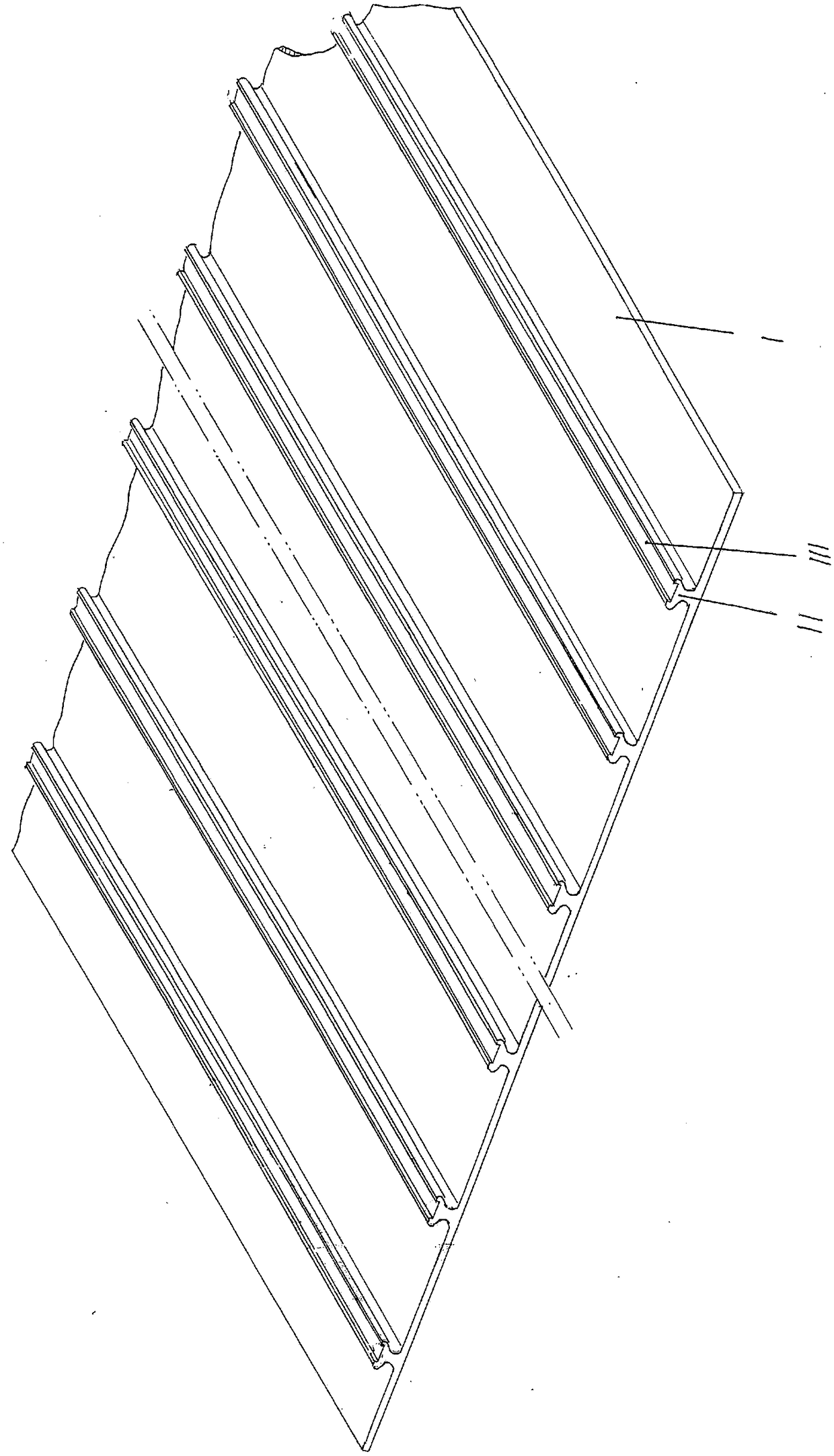

[0031] See figure 1 , shows a liner body 1 made of PVC (polyvinyl chloride) and extruded through an extrusion die. In the state of use of the liner body 1, the side facing the reinforced concrete is formed with protrusions on the liner body 1 in a spaced state The surface of the T-shaped fixed key 11.

[0032] As the technical points of the technical solution provided by the present invention: on the top surface of the aforementioned T-shaped fixed key 11 and along the length direction of the T-shaped fixed key 11, a T-shaped fixed key that is recessed in the top surface of the T-shaped fixed key 11 is formed. Efficient combination chamber 111, through the T-shaped fixed key synergistic combination cavity 111, the combination effect with reinforced concrete can be significantly improved, and the situation of separation from reinforced concrete will not occur in the future service process.

[0033] In this embodiment, the web width of the aforementioned lining body 1 is 1350 m...

Embodiment 2

[0035] Only change the format width of lining body 1 into 1460mm, change the thickness of lining body 1 into 1.5mm, change the height of T font fixed key 11 into 8mm, change the width of the top of T font fixed key 11 into 6mm, change The spacing between two adjacent T-shaped fixed keys 11 is changed to 72mm, and the rest are the same as the description of embodiment 1.

Embodiment 3

[0037] Only the format width of lining body 1 is changed into 1540mm, the thickness of lining body 1 is changed into 3mm, the height of T font fixed key 11 is changed into 10mm, the width of the top of T font fixed key 11 is changed into 8mm, two The spacing between adjacent T-shaped fixed keys 11 is changed to 70mm, and the rest are the same as the description of embodiment 1.

[0038] Construction example 1:

[0039] This construction example is for the lining body 1 described in Embodiment 1, and the construction site is the ground.

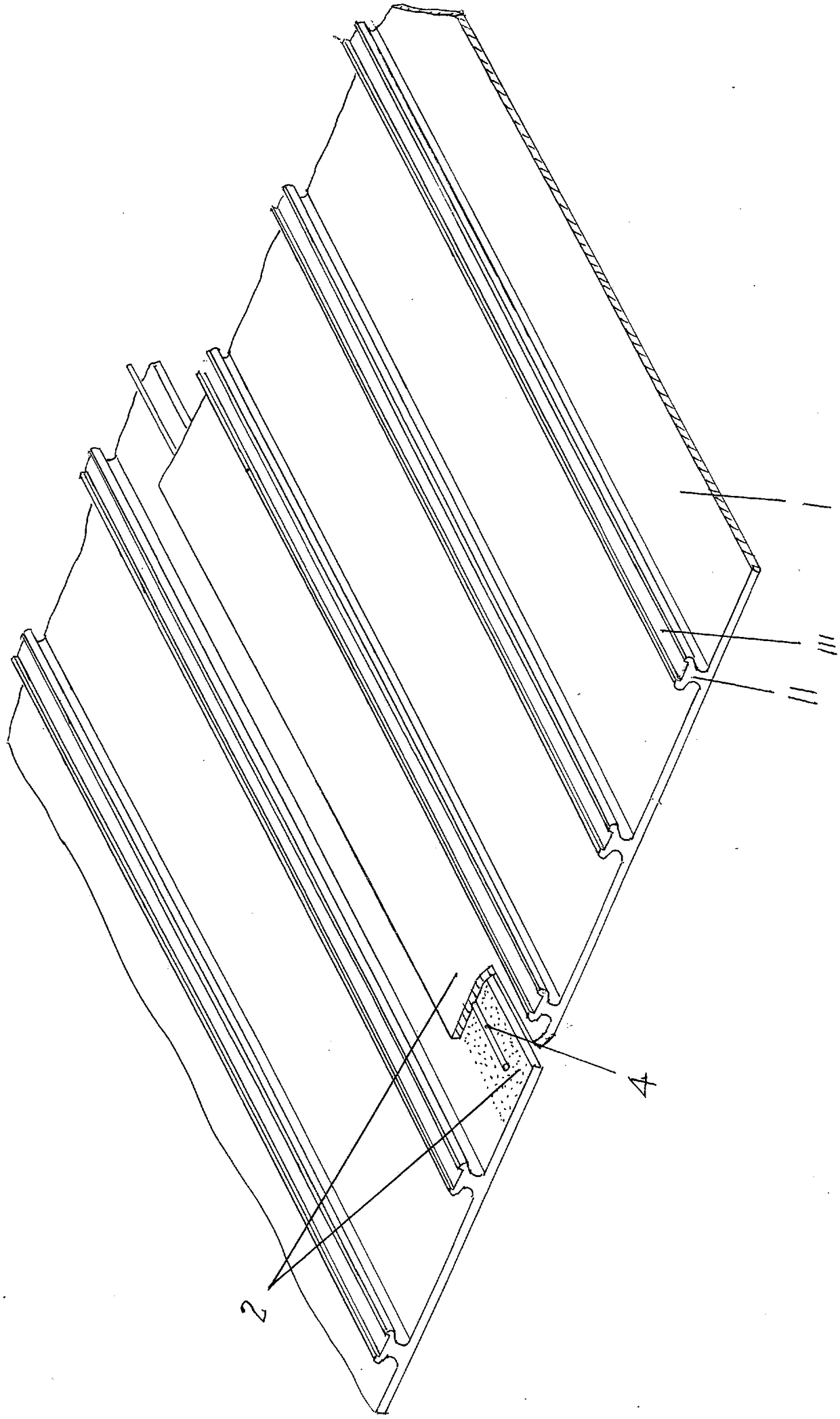

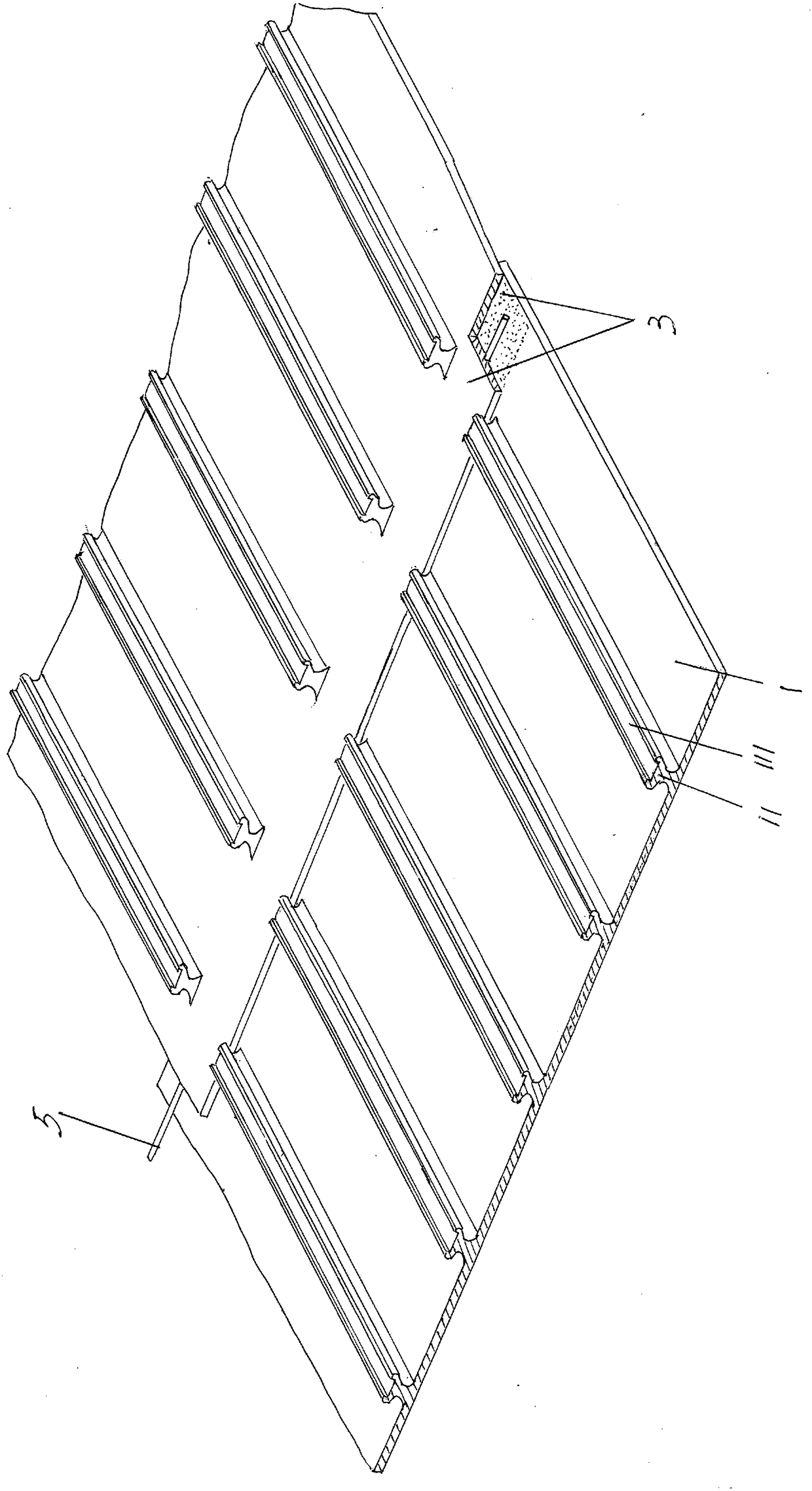

[0040] See figure 2 with image 3 and combine figure 1 , the construction method of PVC protective lining of the present invention comprises the following steps:

[0041] A) laying, will be done by figure 1 The side of the liner body 1 shown with the T-shaped fixed key 11 faces the poured reinforced concrete, and the T-shaped fixed key 11 is inserted into the reinforced concrete, and the edge positions of the long sides of the two adjace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com