PDC drill bit with module cutting teeth

A technology of cutting teeth and drill bits, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of reduced service life of drill bits, rapid drop in specific pressure, breakthroughs and changes in the ROP and service life of drill bits, etc. The effect of rapid increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

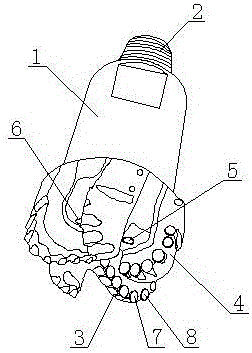

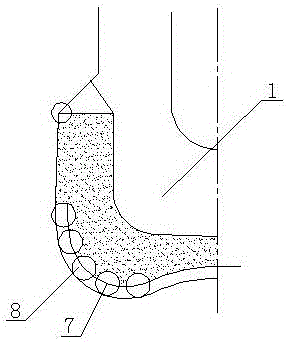

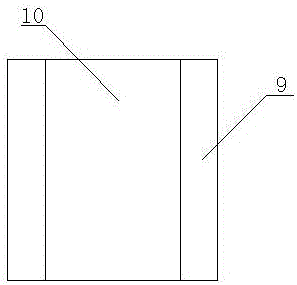

[0025] Such as figure 1 and figure 2 As shown, the PDC bit with modular cutting teeth includes a bit body 1 and a bit joint 2 arranged at one end of the bit body 1, and the other end of the bit body 1 is provided with a plurality of main blades 3 and a plurality of auxiliary blades 4 at intervals. The nose and side of the wing 3 and the auxiliary blade 4 are respectively provided with a plurality of main cutting teeth, the diameter of the main cutting is at least 100 mm, and the number of blades is at least 3. The main cutting teeth include wear-resistant modular cutting teeth 7 and anti-shock type modular cutting teeth 8, such as image 3 and Figure 4 As shown, the wear-resistant modular cutting tooth 7 and the impact-resistant modular cutting tooth 8 are both cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com