Upper corner treatment method for large-dip-angle mining work face

A treatment method and technology of working face, applied in mining equipment, ground mining, mining equipment, etc., can solve problems such as large personal safety hazards, abnormal gas gushing, spontaneous combustion of leftover coal, etc., to ensure safe production and low labor intensity , The effect of small construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Take the typical sharply inclined working face of a mine in Xinjiang as an example to illustrate.

[0047] The basic situation of the working face is as follows:

[0048] The inclination angle of the working face is 45°, the inclination length is 114-136m, the thickness of the coal seam: generally between 2.23m-4.79m, the average thickness is 4.2m, and the variation coefficient is 45%;

[0049] The hardness of the coal (the upper part is hard, the lower part is soft, and there are 300-400mm mudstone inclusions in the middle), the upper part f=2~2.5, and the lower part f≈1. There is hard sandstone 20m above the working face, and the thickness is relatively large, and the f value is 4;

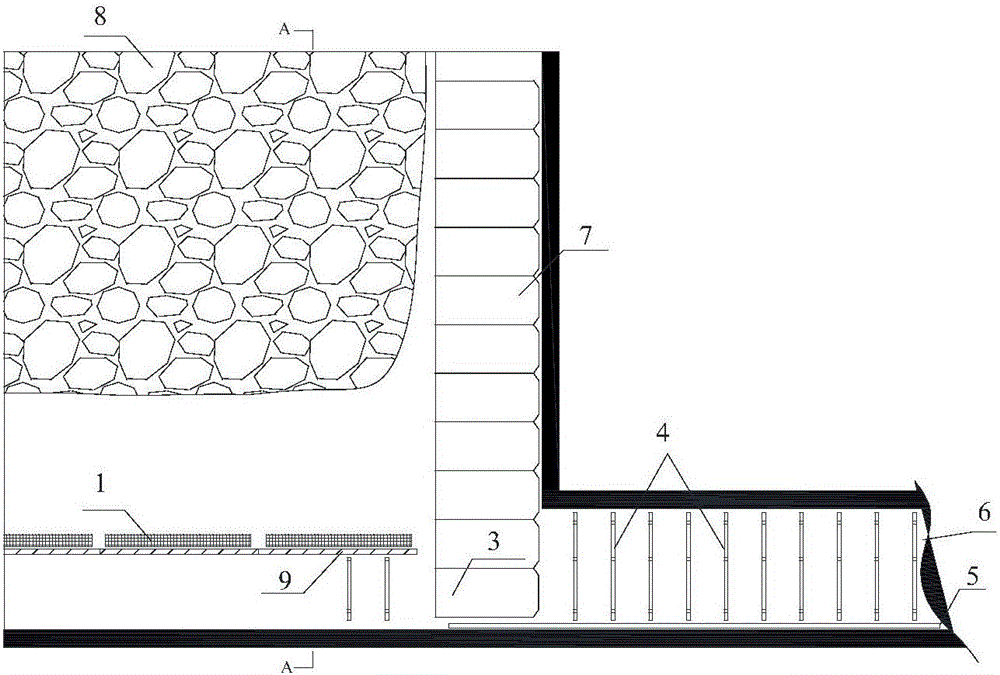

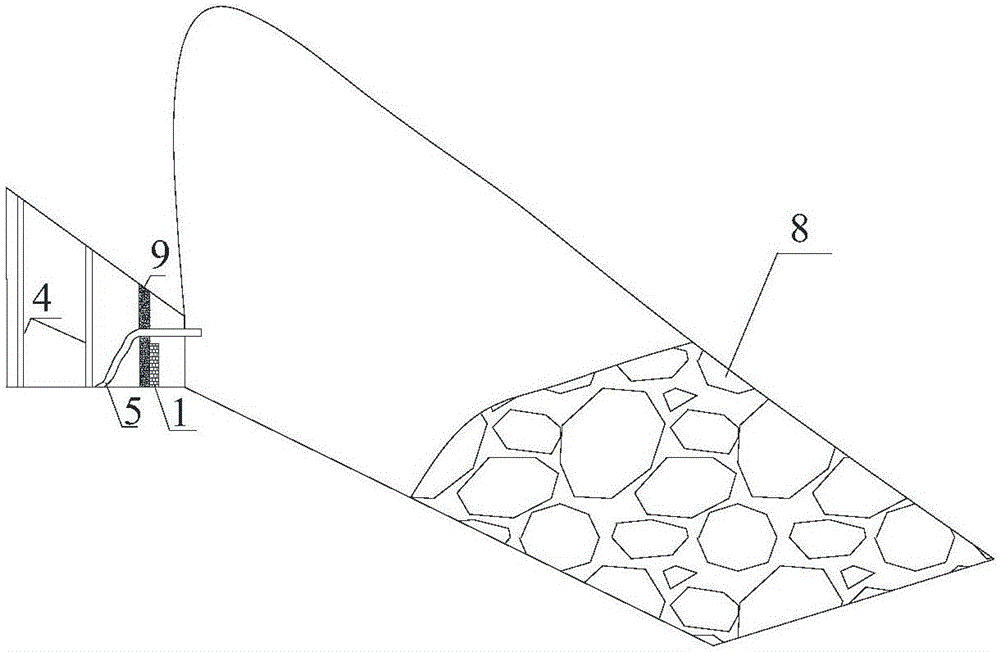

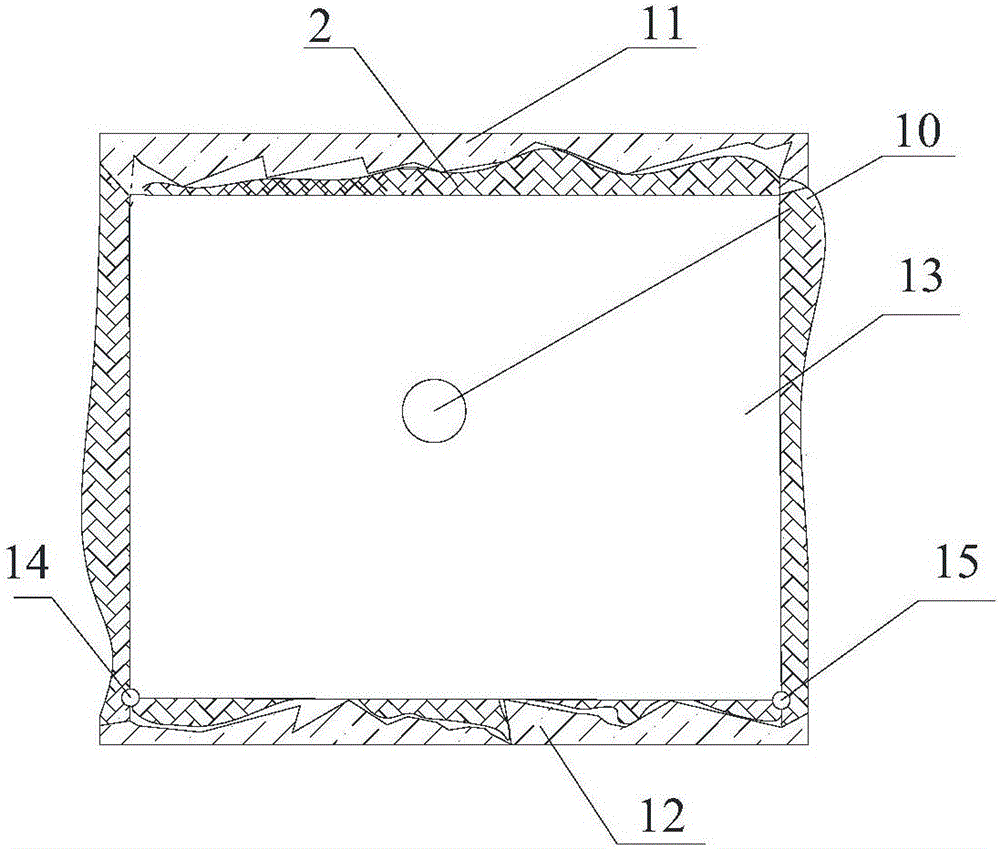

[0050] During the mining process of the working face, the roof does not collapse for a long time at the position of the upper corner along the trough, and the upper trough is connected with the goaf to form a large area of triangular space, and the gas concentration at the corner positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com