Remaining fuel recovery system for fuel tank of scraped car and working method of remaining fuel recovery system

A recycling system, a technology for scrapped cars, applied in the charging system, the layout combined with the fuel supply of the internal combustion engine, vehicle components, etc., can solve the problem of incomplete fuel recovery and other problems, and achieve a small footprint, flexible movement, and good convenience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

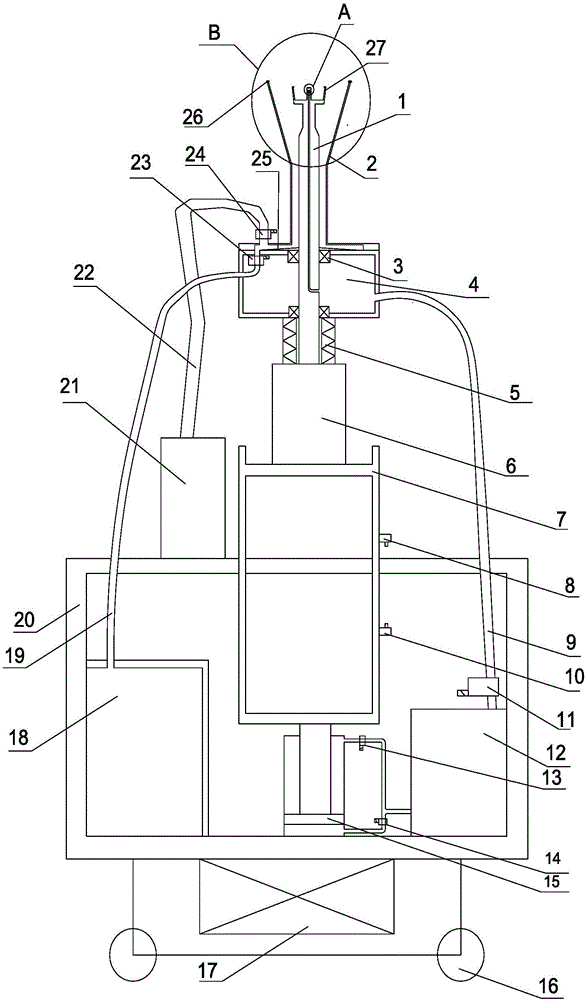

[0033] Such as Figure 1-3 , a recovery system for the remaining fuel in fuel tanks of scrapped vehicles, including a recovery system and a walking system that drives the movement of the recovery system, the recovery system includes a drilling system for drilling holes at the bottom of the fuel tank, and is used to accept the flow from the hole at the bottom of the fuel tank Fuel receiving system for fuel oil, fuel vapor recovery system for absorbing fuel vapor and control system for comprehensive control of the entire recovery system.

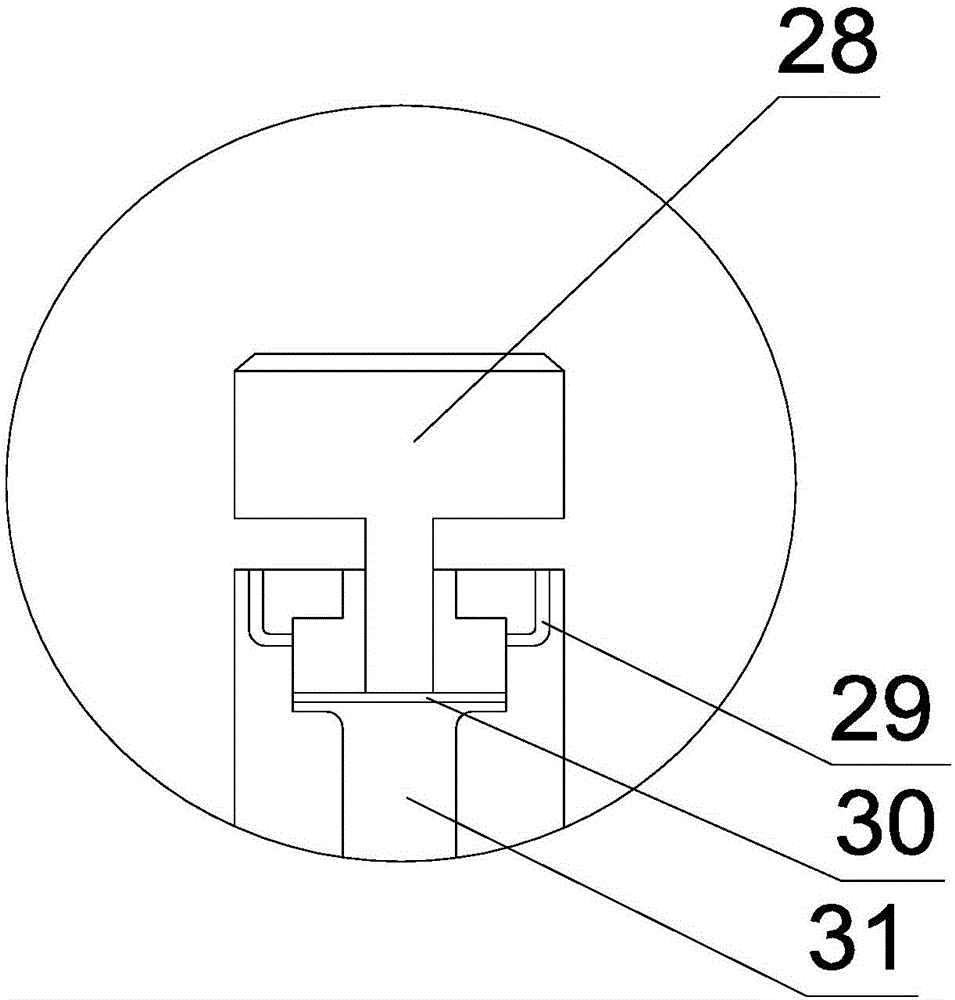

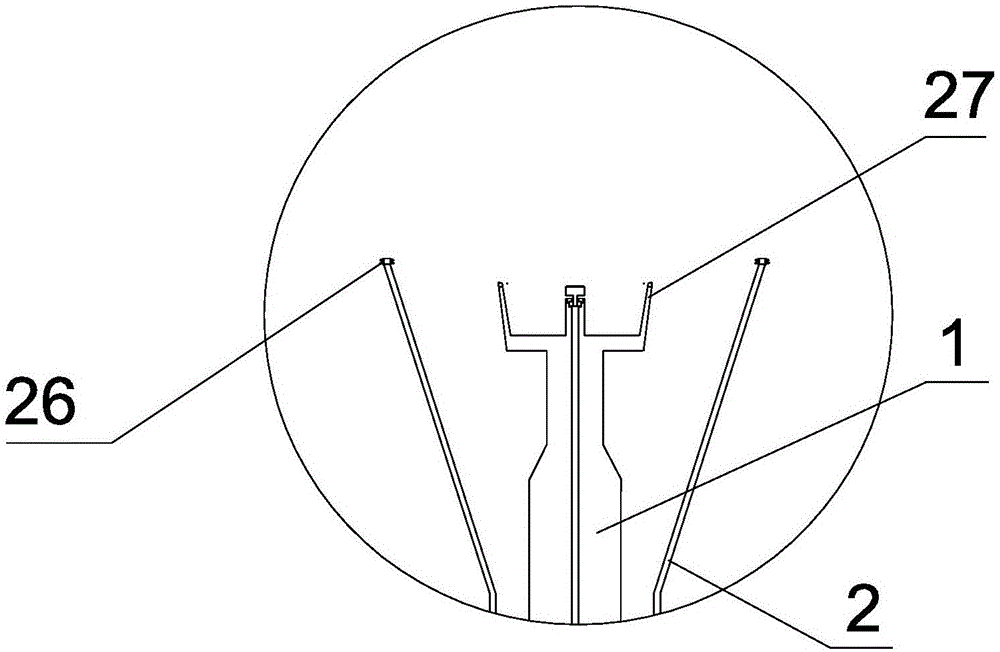

[0034] Such as Figure 1-3 , the drilling system includes a motor support 7, and a lifting device is provided below the motor support 7. In the present embodiment, the lifting device is a pneumatic cylinder 15, which is connected with a pneumatic cylinder descending electromagnetic valve 13 and a pneumatic cylinder rising electromagnetic valve. Air valve 14, drilling motor 6 is fixed on the motor support 7, is connected with knife rest 1 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com