A feedforward control method for steam temperature of thermal power unit

A feedforward control, steam temperature technology, applied in the control of superheat temperature, steam superheat, steam generation, etc., can solve the problems of poor quality and difficult control, and achieve the effect of simple debugging, improved effect, and improved control quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

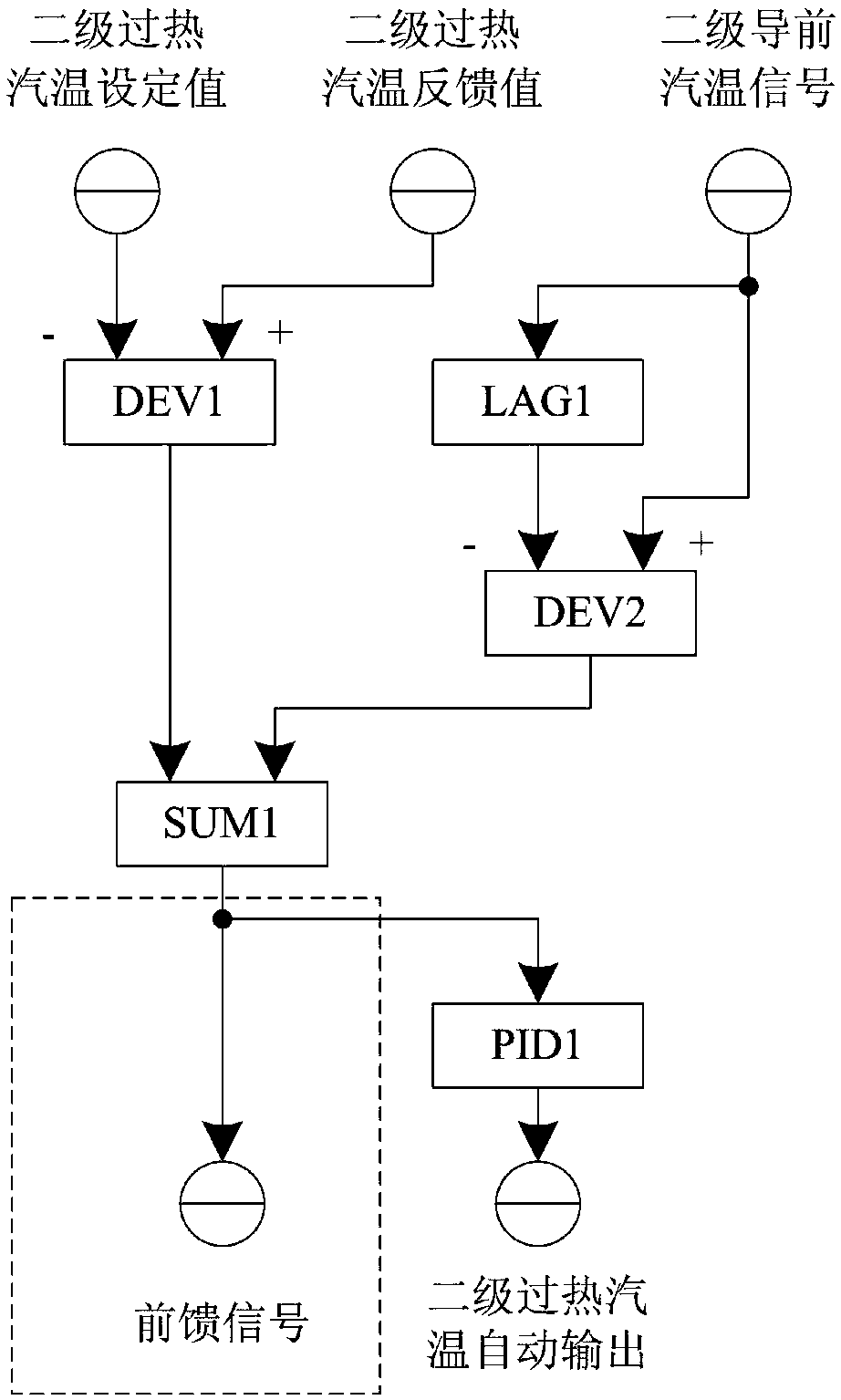

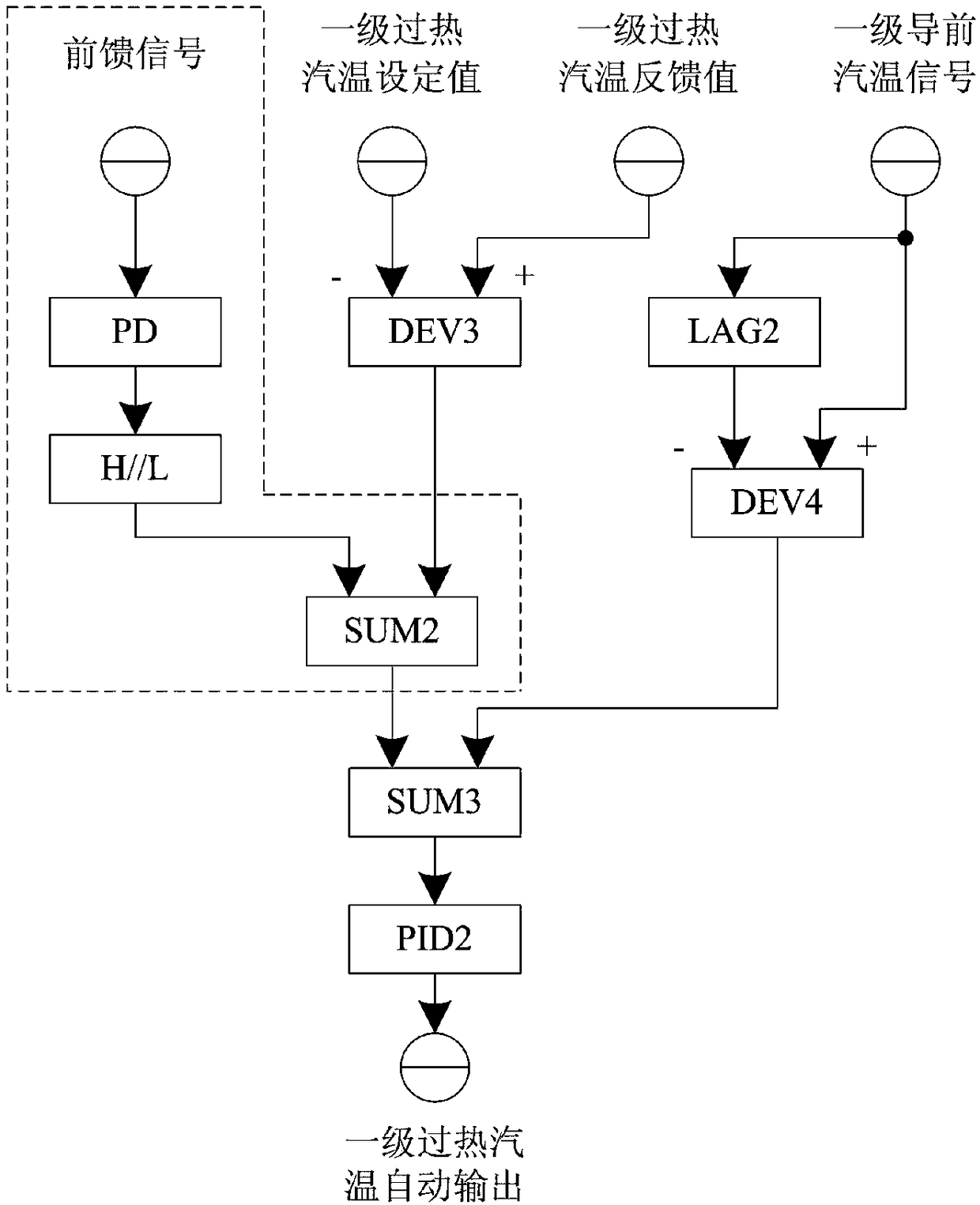

[0016] The first-stage superheated steam temperature of the thermal power unit is the outlet steam temperature of the panel superheater. The panel superheater is composed of two parts in series, the front panel and the rear panel. The inertia time of the object under rated load is about 200s~250s; The outlet steam temperature, the inertia time of the object under rated load is about 90s~110s; The object inertia time is around 340s ~ 420s. Because the inertia time of the object is small, the secondary superheated steam temperature is relatively easy to control.

[0017] The structure of the steam-water system and the air-flue gas system of the boiler determines that the disturbances received by the primary and secondary superheated steam temperature and reheated steam temperature control systems are basically the same, and the change trend of the steam temperature is basically the same when disturbed. In this way, there is the possibility of finding the feed-forward signal fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com