Oil screen used for range hood and range hood applying oil screen

A technology of range hood and oil net, applied in the application, removal of oil fume, household stove, etc., can solve the problem of limited adjustment effect, etc., and achieve the effect of high production efficiency, low cost and noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

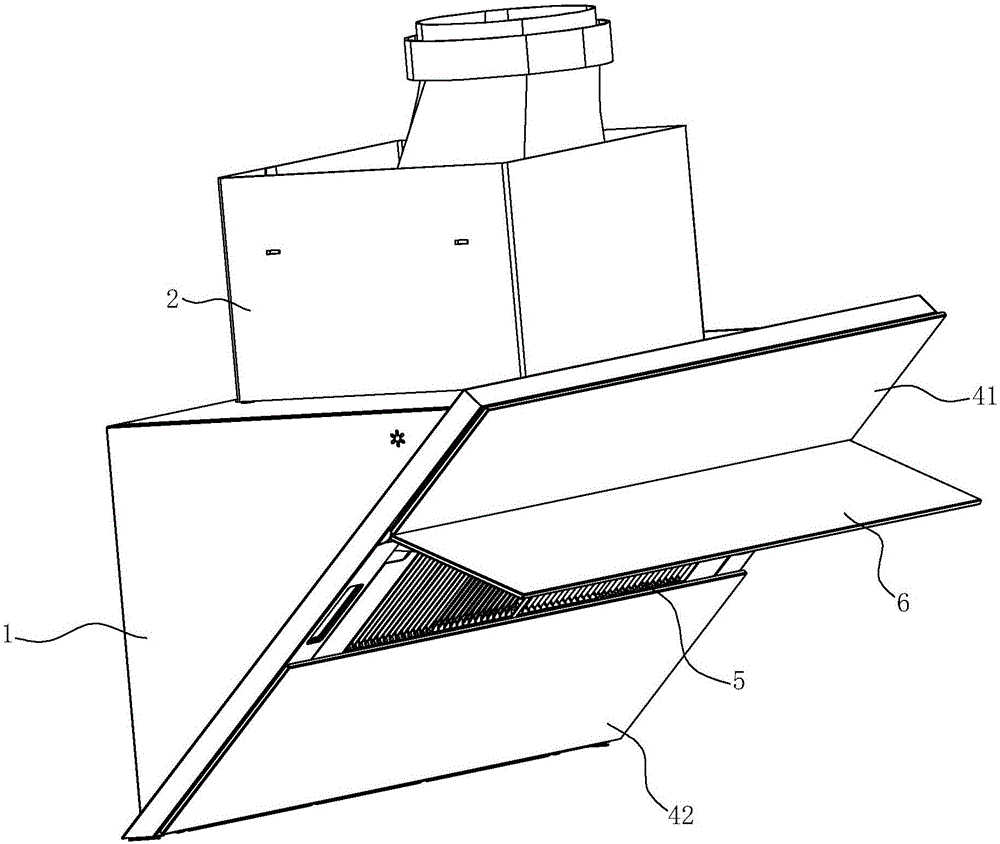

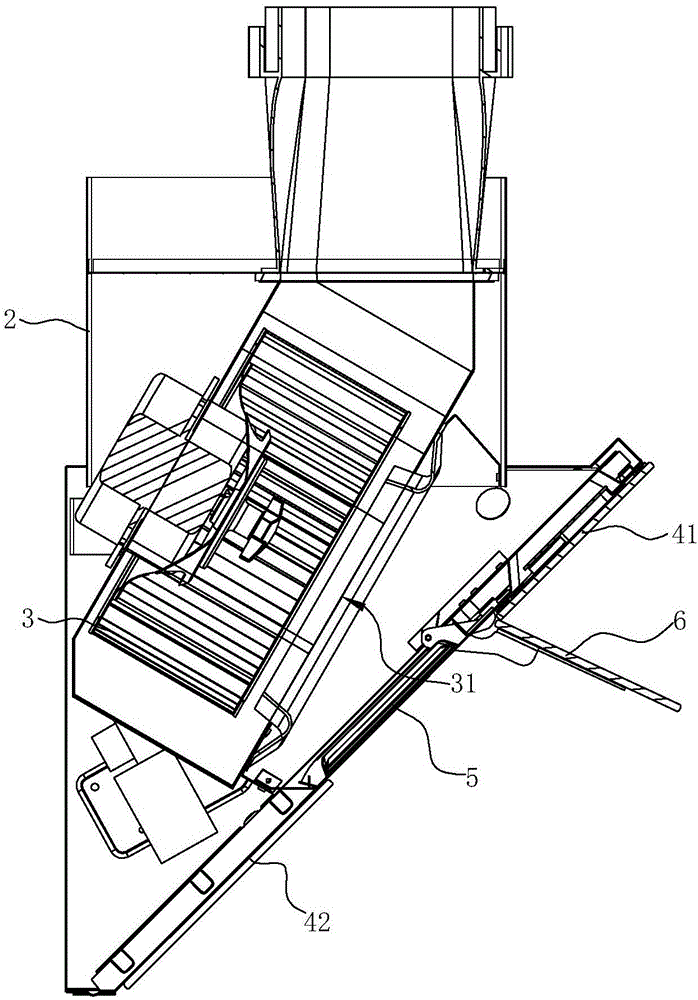

[0031] see Figure 1 to Figure 4 , a range hood. In this embodiment, it is a near-suction range hood, including a smoke collection hood 1, a fan cover 2 and a fan 3. The smoke collection hood 1 is installed under the fan cover 2, and the fan 3 is installed under the fan cover. 2 and partially located on the back side of the fume hood 1.

[0032] The front of the fume collecting hood 1 is provided with panels, including an upper panel 41 and a lower panel 42 , an oil screen 5 is arranged between the upper panel 41 and the lower panel 42 , and the side of the fan 3 facing the oil screen 5 has an air inlet 31 . A rotatable smoke baffle 6 is arranged above the oil screen 5 . When the range hood is turned on, the smoke baffle 6 is turned upwards to expose the oil net 5 , and when the range hood is turned off, the smoke baffle 6 is turned downwards to cover the oil net 5 .

[0033] The oil screen 5 includes a frame 51 and a plurality of blades arranged in the frame 51 , the frame ...

Embodiment 2

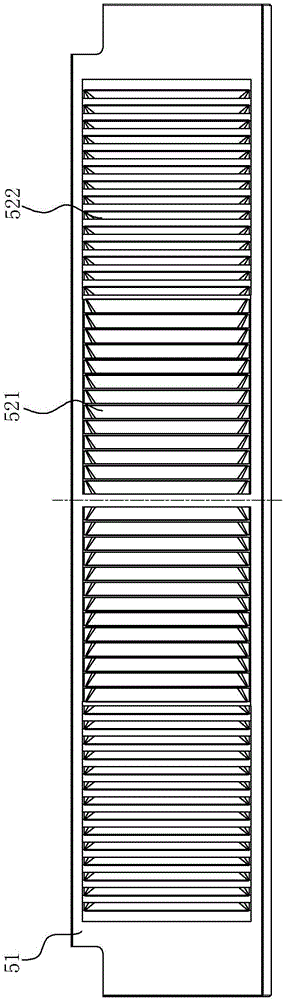

[0051] see Figure 5 with Image 6 , in this embodiment, the difference from the first embodiment above is that the air intake angles of the first vane 521 and the second vane 522 (the angle between the two planes formed by obliquely setting relative to the frame 51) are the same, both is α, the width of each blade is L, the distance between the first blades 521 is d, and the u between the second blades 522 is di, the above parameters satisfy the following relationship: d

[0052] d>L, this is to ensure one-time processing through the mold and save costs;

[0053] L>d*cosα, this is to ensure that adjacent first blades 521 and second blades 522 project overlapping parts along the direction of the vertical blades, thereby ensuring the guiding effect of the first blades 521 and the second blades 522;

[0054] 20°

[0055] The closer the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com