High-power cylindrical gear comprehensive performance test bench with stepless adjustable center distance

A cylindrical gear and comprehensive performance technology, which is applied in the field of high-power cylindrical gear comprehensive performance test bench, can solve the problems of not being able to change the center distance at will, time-consuming and laborious disassembly, and staying in place, so as to meet long-term frequent tests and avoid repeated disassembly Fast assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and example the present invention will be further described

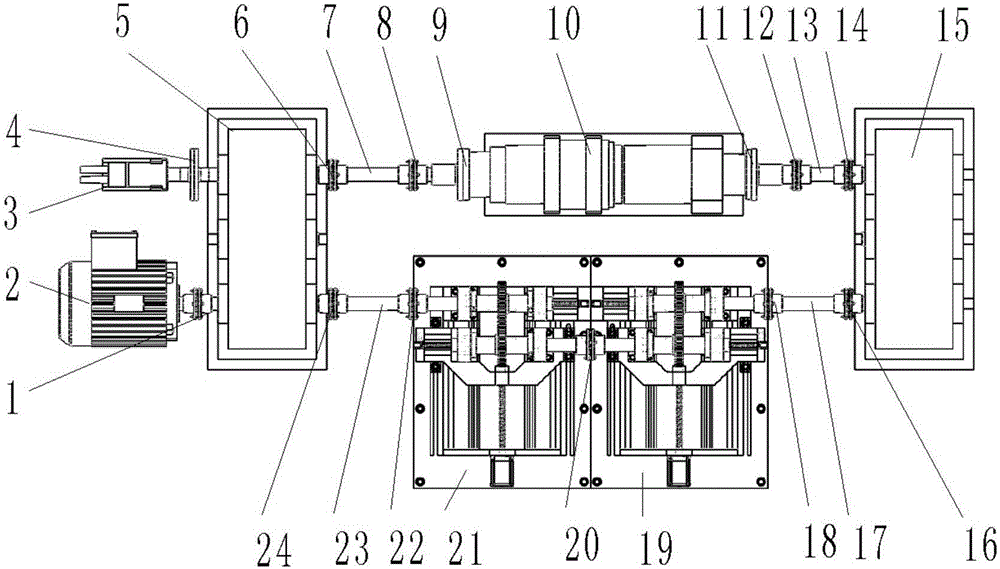

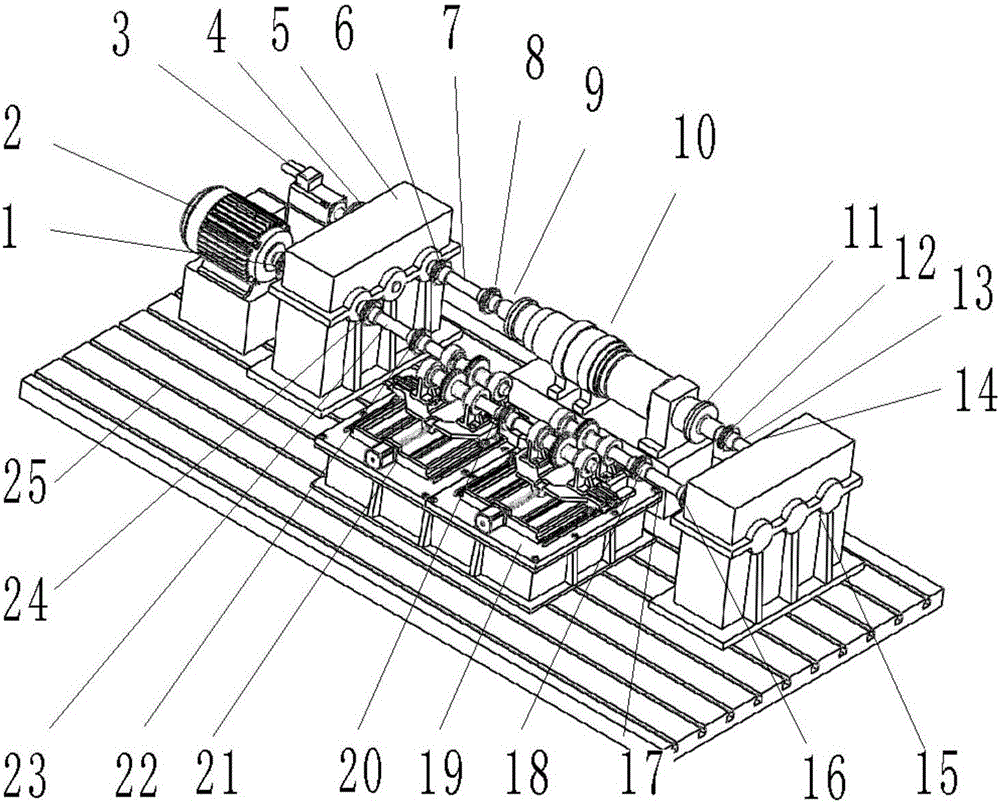

[0032] Such as figure 1 and 2As shown, the present invention comprises frequency conversion AC motor (2), servo motor (3), two closed cylindrical gear boxes (5, 15), hydraulic swing cylinder (10), main test bench (21), accompanying test bench (19), ten elastic couplings (1,6,8,12,14,16,18,20,22,24), four intermediate transmission shafts (7,13,17,23), two links flanges (9,11), a clutch (4). One side on the floor iron (25) is installed frequency conversion alternating current motor (2), starts from servomotor (3), installs first closed cylinder gear box (5), hydraulic swing cylinder (10), The second enclosed cylindrical gear box (15), the companion gear test stand (19), the main test gear test stand (21), and the variable frequency AC motor (2).

[0033] On the side of the floor iron, the output end of the servo motor (3) is connected with the second input end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com