Multifunctional combustion testing device and method for simulating engine conditions

A combustion test, multi-functional technology, applied in the direction of internal combustion engine test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

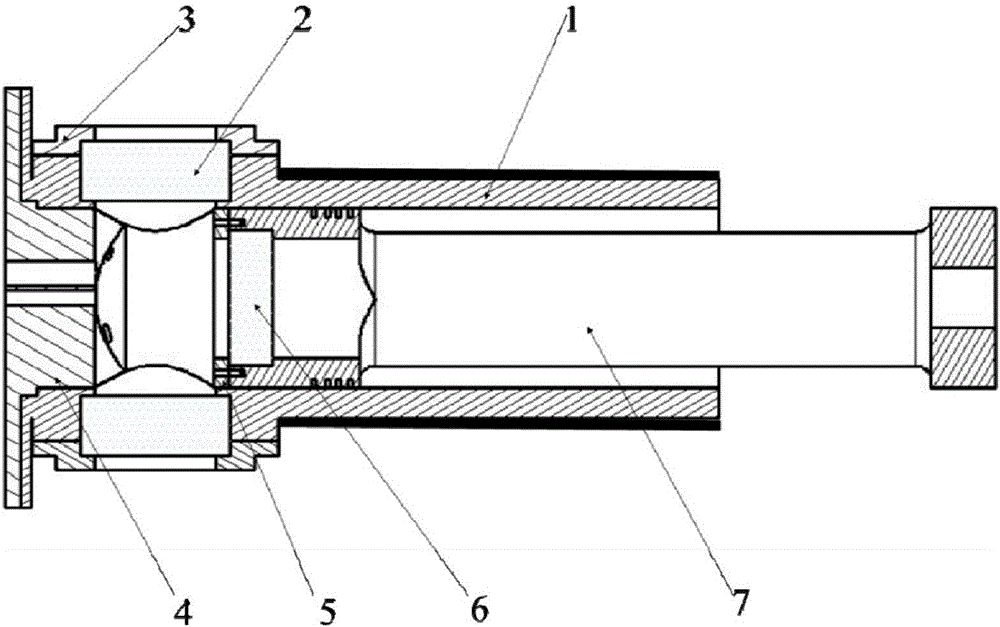

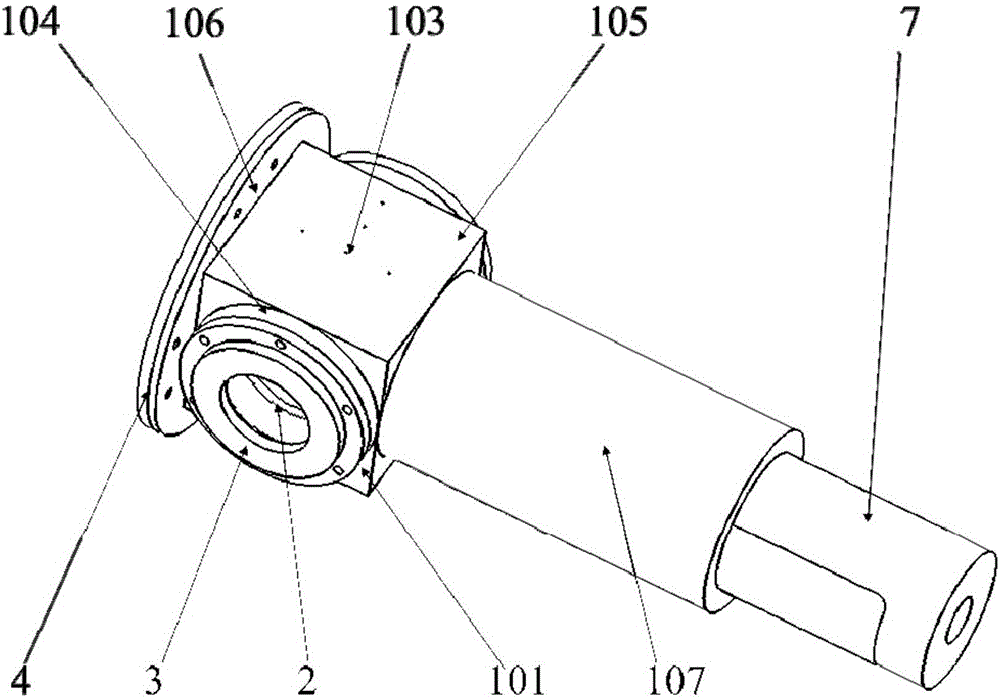

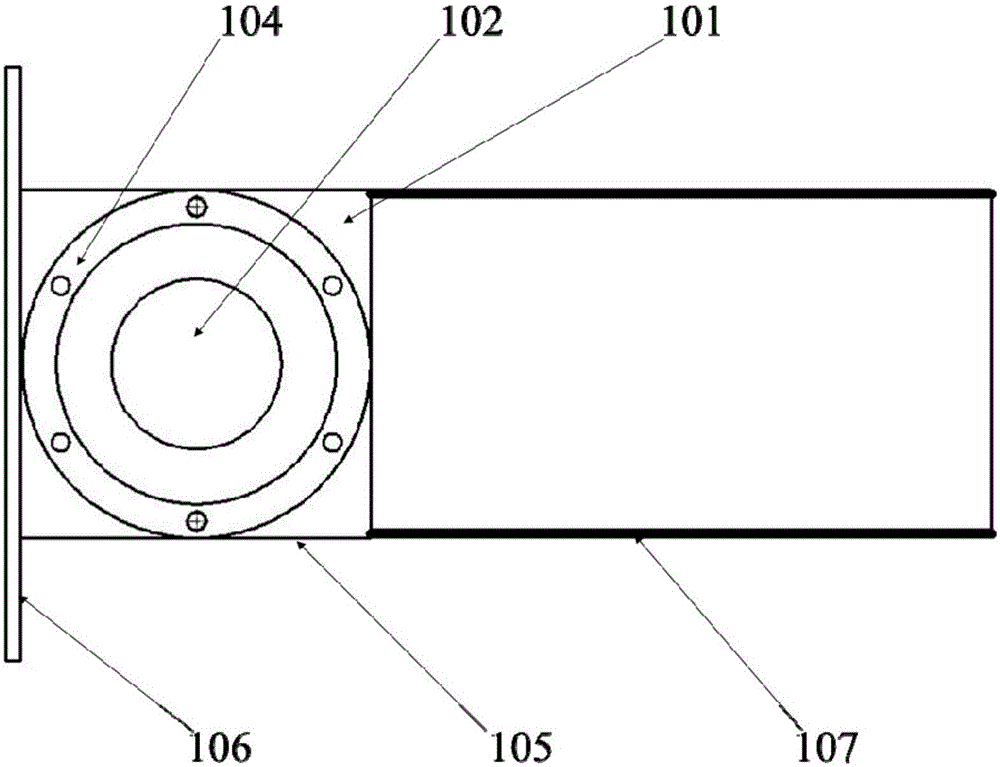

[0082] The device mainly includes: device main body 1 main body quartz glass 2 main body quartz glass gland 3 end cap 4 piston quartz glass gland 5 piston quartz glass 6 piston 7

[0083] Optical window plane 101 Main body optical through hole 102 Sampling through hole 103 Through hole boss 104 Sampling hole plane 105 Main body top plate 106 Heating belt 107

[0084] End cap top plate 401 End cap boss 402 Optical path groove 403 Spark plug through hole 404 Nozzle through hole 405 Air intake pipe threaded hole 406 Exhaust pipe threaded hole 407 Pressure sensor through hole 408 Temperature sensor through hole 409

[0085] Plug tail 701 Piston skirt 702 Piston head 703 Piston optical through hole 704 Piston ring groove 705 Piston stroke groove 706 Tail through hole 707

[0086] The device main body 1 is divided into two sections, front and rear. The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com