Combustion particle image acquisition device and method

An image acquisition device and particle technology, applied in the field of optical imaging, can solve the problems of indistinguishable flame front and particle shape, excessive light intensity between particles and flame, and indistinguishable particle and flame, so as to improve the success rate and accuracy, Effects with high image quality and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the embodiments described below by referring to the figures are examples, and are only for explaining the present invention, and should not be construed as limiting the present invention.

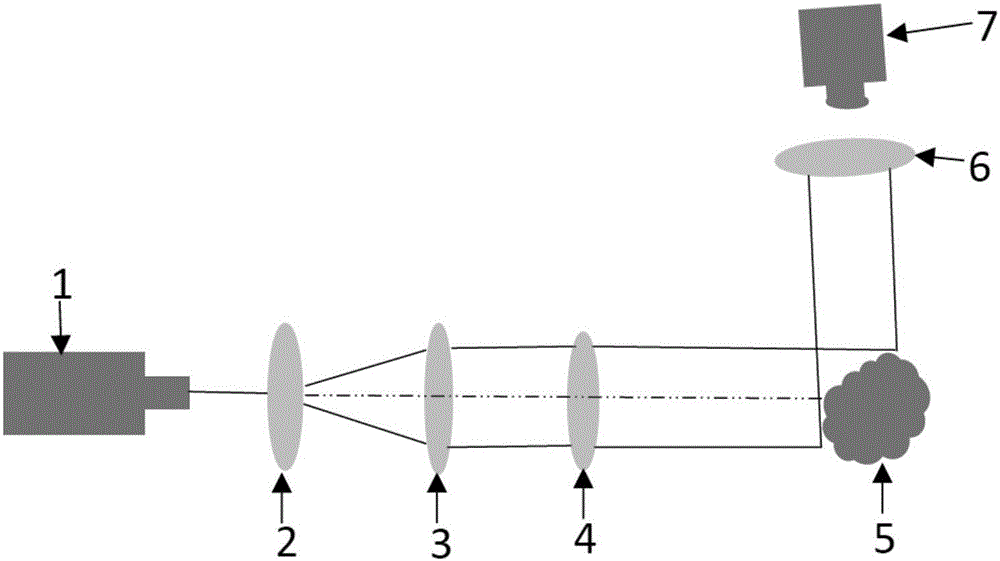

[0016] figure 1 It is a schematic diagram of the structure of a burning particle image acquisition device proposed by an embodiment of the present invention. The device includes a laser active light source 1, a beam expander lens 2, a collimating lens 3, an attenuation plate 4, a burning particle placement platform 5, an optical filter 6 and a camera 7.

[0017] Laser active light source 1, which provides a light source whose wavelength band does not intersect with the particle combustion emission light band 965nm-1931nm, and is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com