Device and method for high temperature melt growth choking experiment

An experimental device, high-temperature melting technology, applied in the investigation phase/state change and other directions, can solve problems such as differences in research conditions and conclusions, limited applicability of existing models, and large uncertainties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] see Figure 5 , the present invention includes an operating piano cabinet 19, a transformer 20, a multi-channel data acquisition system, a programmable temperature control system, a thyristor, a thyristor trigger, and a heating furnace.

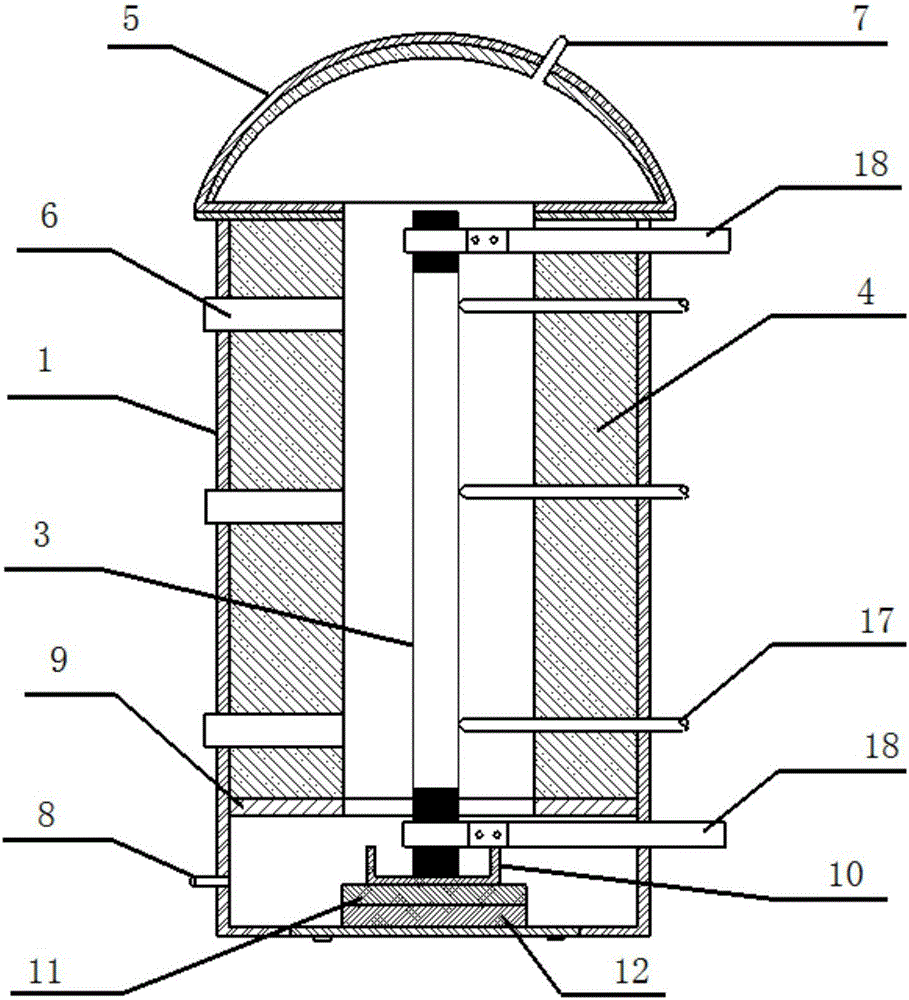

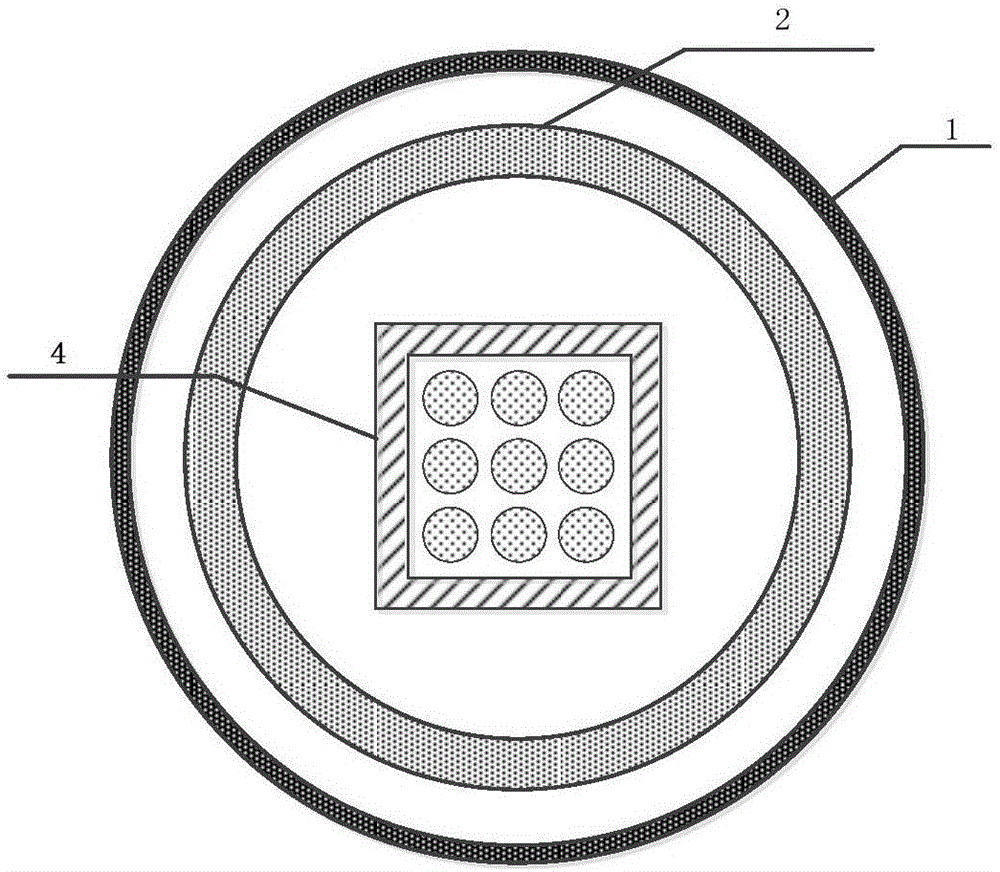

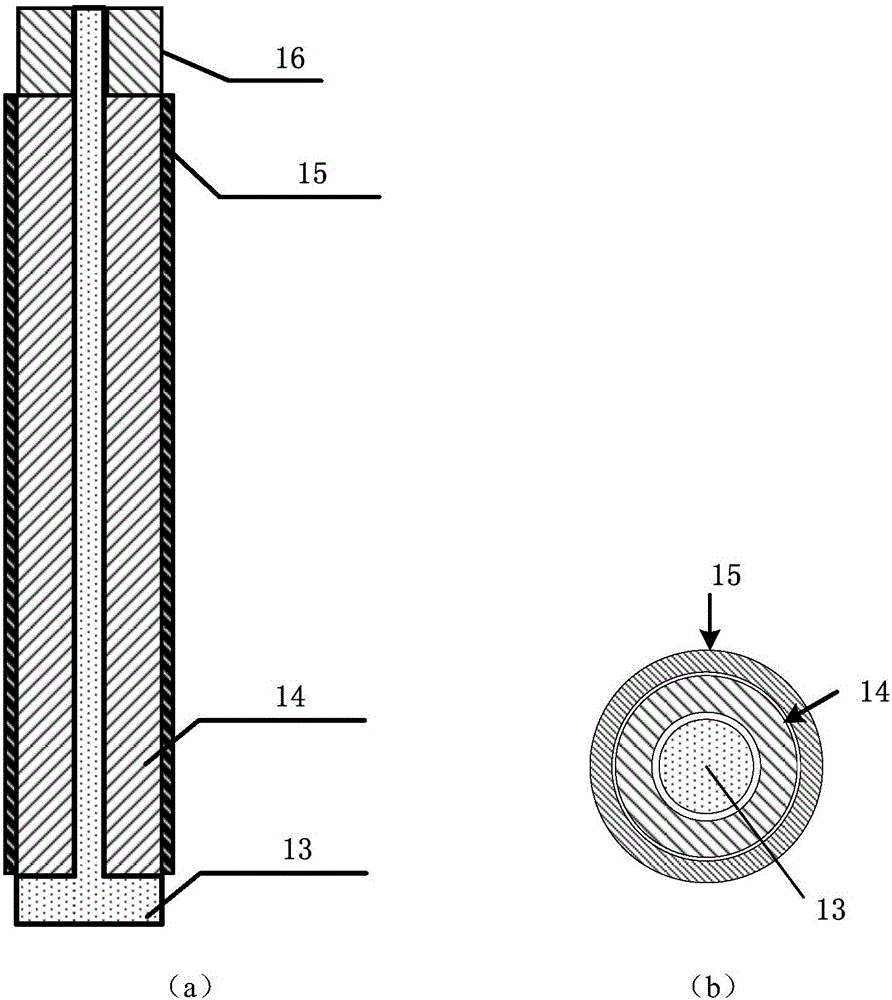

[0034] see figure 1 , the heating furnace includes a furnace body 1, the furnace body 1 is a cylindrical structure, the inner diameter of the heating furnace is 1.0m, the height of the furnace body is 1.5m, and the wall thickness of the furnace body is 0.01m. The top of the furnace body 1 is provided with an arc-shaped furnace cover 5. The arc-shaped furnace cover 5 has a stronger pressure capacity. The furnace cover 5 is provided with an argon gas outlet 7; Heat layer 2, the furnace body 1 is provided with a molybdenum plate 9 for supporting the high temperature heat insulation layer 2; see Figure 5 , the furnace body 1 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com