Self-test auxiliary device and self-test method for visual hardware of distribution terminal

A technology for power distribution terminals and auxiliary devices, applied in the electric power field, can solve problems such as unfavorable large-scale production and management, irregular test reports, and inability to achieve, and achieve the effects of saving external equipment, facilitating aging tests, and facilitating maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

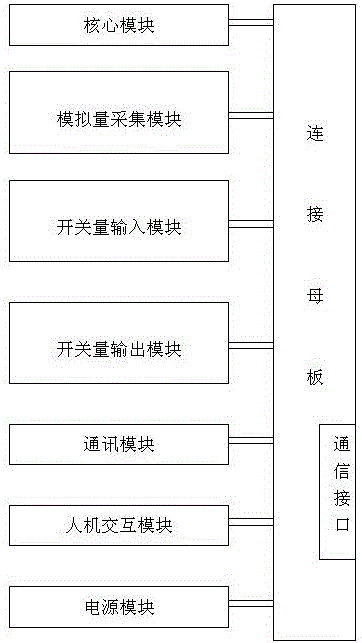

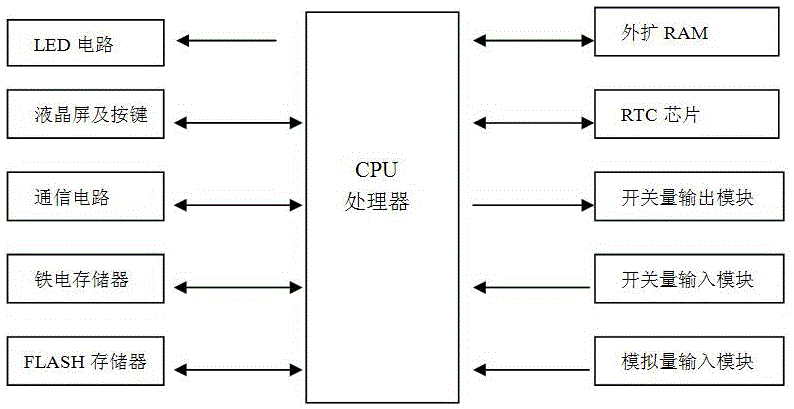

[0042] A visual hardware self-inspection auxiliary device for power distribution terminals, used to detect power distribution terminals, such as figure 2 As shown, the power distribution terminal includes a connecting motherboard and functional modules plugged into the connecting motherboard. The functional modules include an analog acquisition module, a digital input module, a digital output module, a human-computer interaction module, a communication module and a core module. , the core module is equipped with CPU, RTC chip and memory, and the human-computer interaction module includes a set of LED lights and a display screen. Each module is connected to the CPU through the connecting motherboard. The schematic diagram of the power distribution terminal is as follows: image 3 shown.

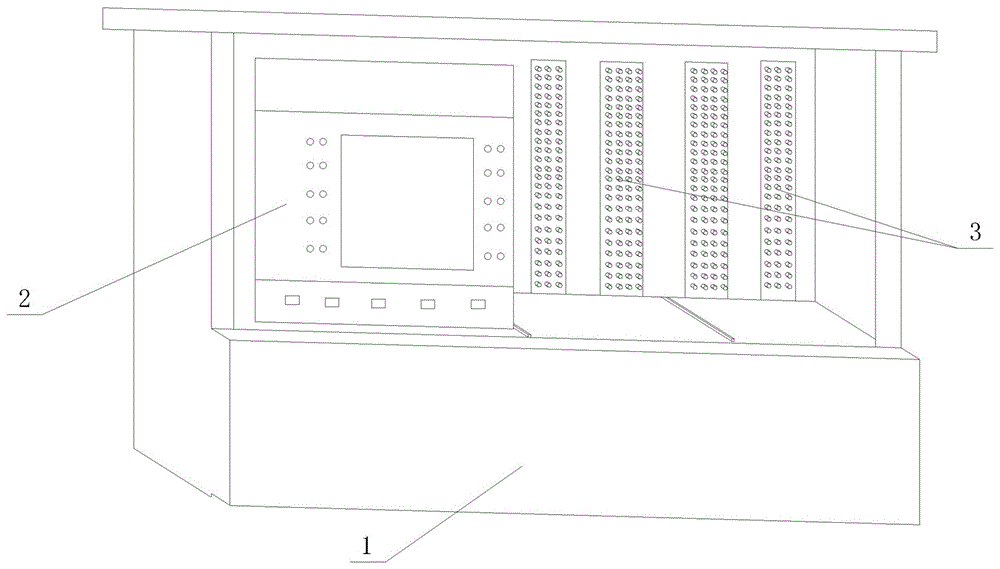

[0043] The auxiliary device includes a test cavity and a connector arranged in the housing 1, such as figure 1 As shown, the connector 3 is located at the back of the test chamber, the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com