Apparatus and method for generating glow discharge striations

A glow discharge and stripe technology, applied in the direction of solid cathode components, cold cathode tubes, etc., can solve the problems of irregular distribution of electron density and electron temperature, no selectivity, complex structure, etc., and achieve rich and stable active particles Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

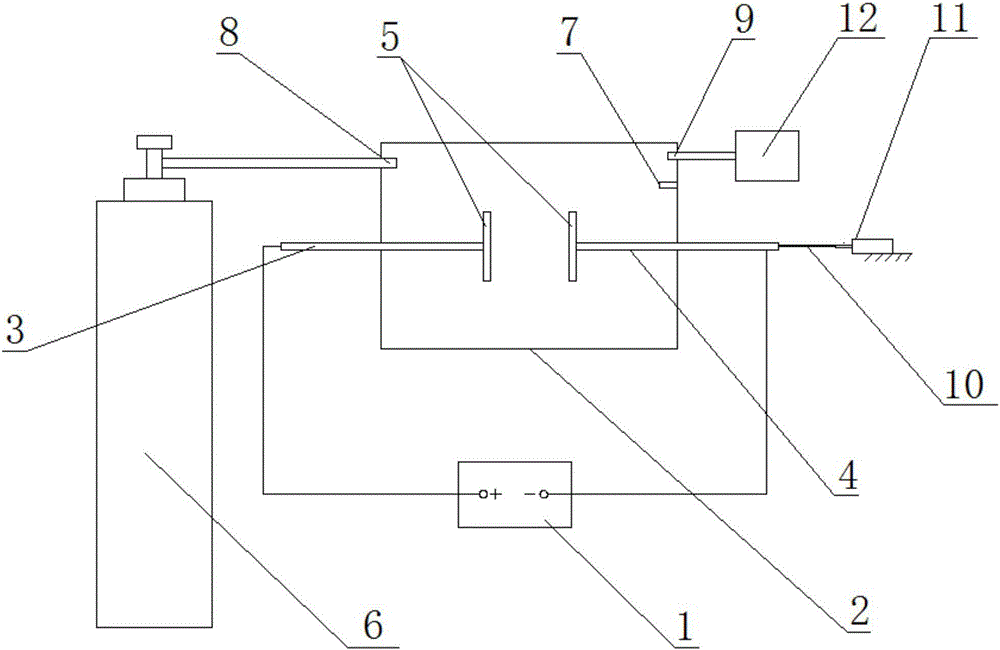

[0019] Such as figure 1 As shown, a device for generating glow discharge stripes in this embodiment includes a DC power supply 1, an anode 3, a cathode 4 and a workbench, wherein: a glow discharge chamber 2 is also included, and the glow discharge chamber 2 One side wall is provided with an argon gas inlet 8, and the other side wall of the glow discharge chamber 2 is provided with a vacuum port 9 and a vacuum degree tester 7, and the glow discharge chamber 2 is connected with the vacuum port 9 The vacuum pumping device 12 is connected, and the glow discharge chamber 2 is connected with the argon gas storage device 6 through the argon gas inlet 8;

[0020] One end of the anode 3 and the cathode 4 are arranged in the glow discharge chamber 2 through the two side walls of the glow discharge chamber 2, and the ends of the anode 3 and the cathode 4 are respectively provided with plate electrodes 5 parallel to each other; The other end of the anode 3 is connected to the positive po...

Embodiment 2

[0030] A method for producing glow discharge stripes with the glow discharge stripe device in embodiment 1, comprising the following steps:

[0031] 1) Install and connect various instruments and equipment, and check their tightness and insulation;

[0032] 2) The vacuum pumping device 12 draws air outwards through the vacuum port 9, and observes the vacuum degree tester 7 at the same time until the air pressure in the glow discharge chamber 2 is maintained at 8kpa, and the pumping is stopped;

[0033] 3) Fill the glow discharge chamber 2 with argon gas with a concentration of 99.999% through the argon gas inlet 8, and observe the vacuum degree tester 7 at the same time, so that the air pressure in the glow discharge chamber 2 is maintained at 9kpa, and the air intake is stopped. ;

[0034] 4) Turn on the DC power supply 1, and then gradually increase the voltage, so that the gas breaks down and a glow discharge plasma is formed between the plate electrodes 5;

[0035] 5) Ad...

Embodiment 3

[0037] A method for producing glow discharge stripes with the glow discharge stripe device in embodiment 1, comprising the following steps:

[0038] 1) Install and connect various instruments and equipment, and check their tightness and insulation;

[0039] 2) The vacuum pumping device 12 draws air outwards through the vacuum port 9, and observes the vacuum tester 7 at the same time until the air pressure in the glow discharge chamber 2 is maintained at 8.1kpa, and the pumping is stopped;

[0040] 3) Fill the glow discharge chamber 2 with argon gas with a concentration of 99.999% through the argon gas inlet 8, and observe the vacuum degree tester 7 at the same time, so that the air pressure in the glow discharge chamber 2 is maintained at 9.1kpa, and stop charging. gas;

[0041] 4) Turn on the DC power supply 1, and then gradually increase the voltage, so that the gas breaks down and a glow discharge plasma is formed between the plate electrodes 5;

[0042] 5) Adjust the vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com