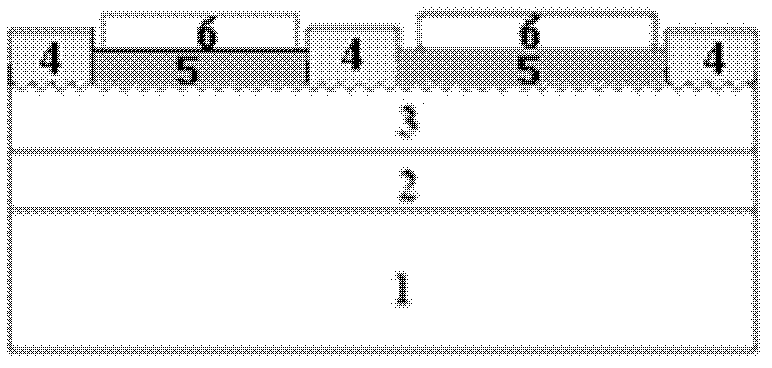

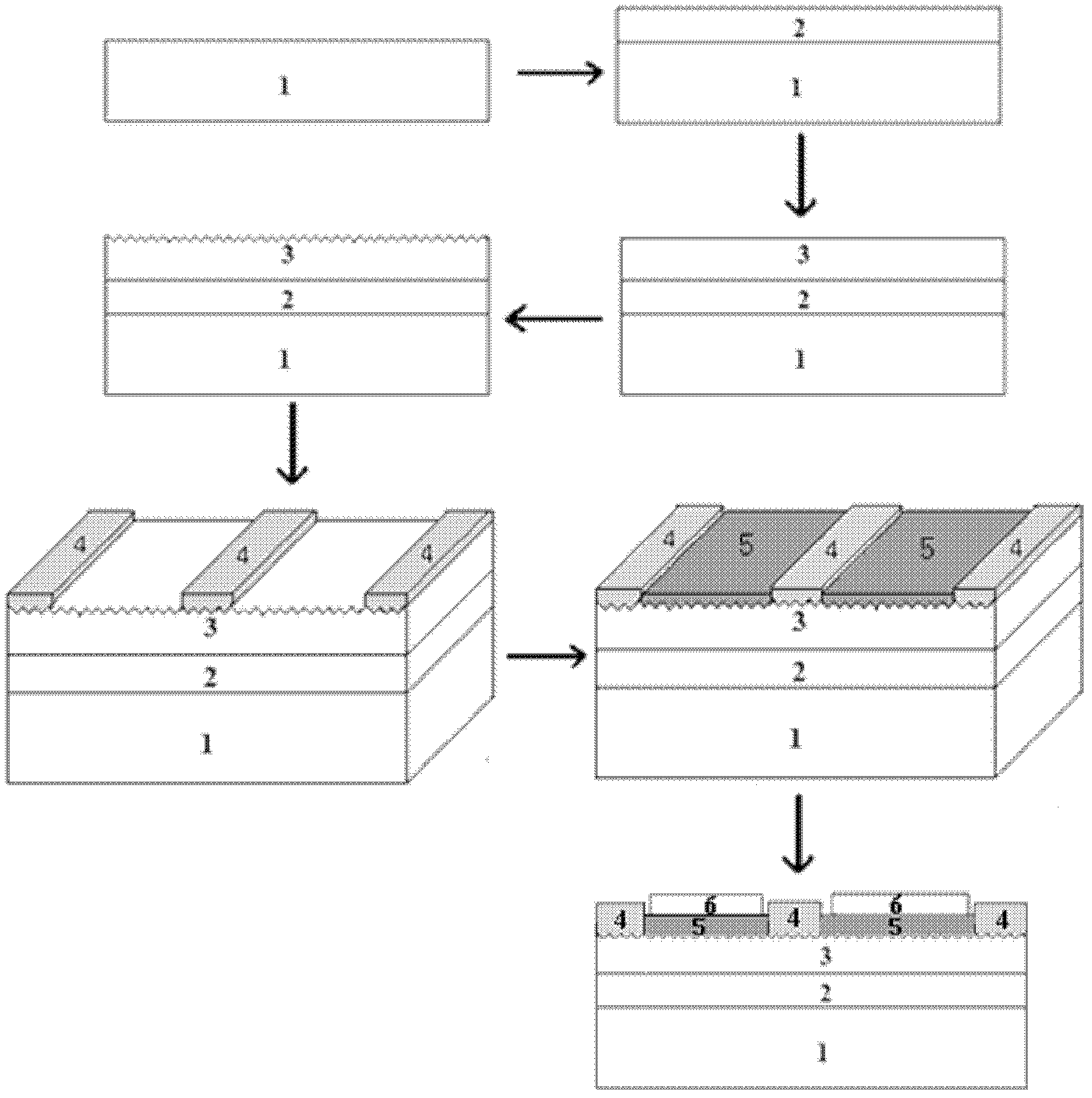

Nitrogen-faced gallium nitride suede solar cell and fabrication method thereof

A technology of solar cells and manufacturing methods, applied in the field of microelectronics, can solve the problems of low photoelectric conversion efficiency and high production costs, and achieve the effects of easy control of corrosion time and temperature, large short-circuit current, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, comprises the steps:

[0029] Step 1, grow an AlN buffer layer with a thickness of 150nm on the sapphire substrate by MOCVD method, and the process conditions are: temperature is 1050°C, NH 3 It is 3500sccm, TMAl is 30sccm, and the time is 30min.

[0030]Step 2: On the AlN buffer layer, the MOCVD method is used to grow the thickness of 2 μm and the electron concentration of 1.0×10 17 cm -3 -2.0×10 18 cm -3 The nitrogen surface n-GaN epitaxial layer, the process conditions are: the temperature is 1020 ℃, NH 3 It was performed at 5000 sccm, TEGa at 220 sccm, and for 2 hours.

[0031] Step 3, put the sample material after growing the n-GaN epitaxial layer on the nitrogen surface into acetone and absolute ethanol for 3 minutes, respectively, and ultrasonically clean it for 3 minutes, repeat twice, and then use deionized water to clean it ultrasonically for 10 minutes.

[0032] Step 4, add KOH solution with a concentration of 15% into the beaker, heat it ...

Embodiment 2

[0036] Embodiment 2, comprises the steps:

[0037] Step 1, at a temperature of 1050°C, NH 3 Under the process conditions of 3500 sccm, 30 sccm of TMAl, and 30 min, an AlN buffer layer with a thickness of 150 nm was grown on the sapphire substrate by MOCVD method.

[0038] Step 2, using MOCVD method, at a temperature of 1020 ° C, NH 3 Under the conditions of 5000 sccm, TEGa 220 sccm, and a time of 2 hours, the growth thickness on the AlN buffer layer is 2 μm, and the electron concentration is 1.0×10 17 cm -3 -2.0×10 18 cm -3 The nitrogen-faced n-GaN epitaxial layer.

[0039] Step 3, put the sample after growing the n-GaN epitaxial layer on the nitrogen surface into acetone and absolute ethanol for 3 minutes for ultrasonic cleaning respectively, repeat twice and then use deionized water for 15 minutes for ultrasonic cleaning.

[0040] Step 4: Add the prepared KOH solution with a concentration of 20% into the beaker, heat it to 85°C with a universal heating furnace, measure...

Embodiment 3

[0044] Embodiment 3, comprises the steps:

[0045] In step A, an AlN buffer layer with a thickness of 200nm is grown on a sapphire substrate by MOCVD, and the growth process conditions are as follows: temperature is 1050°C, NH 3 It is 3500 sccm, TMAl is 30 sccm, and the time is 40 min.

[0046] Step B, using MOCVD to grow on the AlN buffer layer with a thickness of 3 μm and an electron concentration of 1.0×10 17 cm -3 -2.0×10 18 cm -3 The nitrogen surface n-GaN epitaxial layer, the process conditions are: the temperature is 1020 ℃, NH 3 It is 5000 sccm, TEGa is 220 sccm, and the time is 3 hours.

[0047] In step C, the sample material after growing the n-GaN epitaxial layer on the nitrogen surface is put into acetone and absolute ethanol for 3 minutes, respectively, and ultrasonically cleaned for 3 minutes, and after repeated 2 times, ultrasonically cleaned with deionized water for 12 minutes.

[0048] Step D, add the prepared KOH solution with a concentration of 25% int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com