A photosensitive memory based on quantum dot organic field effect transistor and its preparation method

A technology of quantum dots and transistors, applied in the field of photosensitive memory based on quantum dot organic field effect transistors and its preparation, can solve the problems of difficult device size reduction, narrow absorption spectrum, high operating voltage, etc., and reduce the dependence of operating voltage and absorption spectrum The effect of widening and improving storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

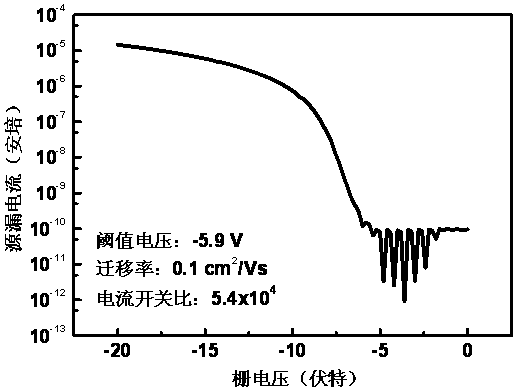

Examples

Embodiment 1

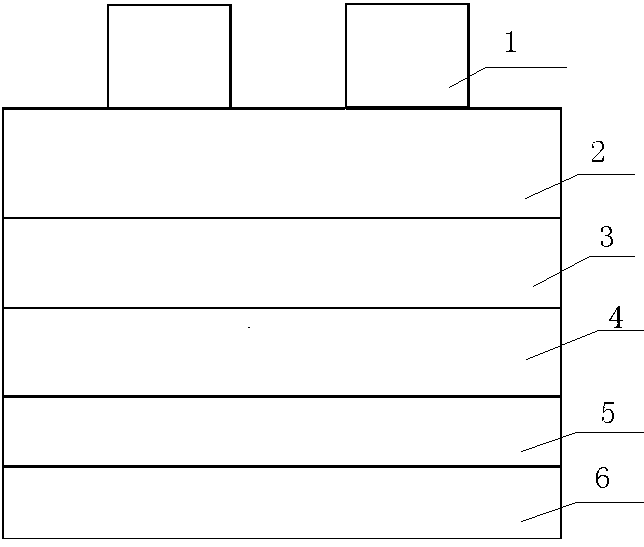

[0030] Such as figure 1 As shown, the first step: prepare a lead sulfide solution, the solvent is toluene, the concentration of the solution is 1 mg / ml, and it is allowed to stand for 30 minutes to make it evenly dispersed;

[0031] Step 2: Select a highly doped silicon wafer as the substrate 6, and sequentially form a gate electrode 5 and a gate insulating layer 4 on the substrate 6. The gate electrode 5 is made of highly doped silicon, and the gate insulating layer 4 is made of silicon dioxide. The thickness of the gate insulating layer 4 is 50nm, and the substrate is made. The substrate is ultrasonically cleaned with acetone, ethanol, and deionized water for 10 minutes, and the ultrasonic frequency is 100 KHz. Then, the liquid on the substrate surface is blown dry with high-purity nitrogen. The surface of the substrate is clean, and then it is dried in an oven at 120°C;

[0032] The third step: Place the dried clean substrate in a UV ozone machine and treat it with UV ozone for ...

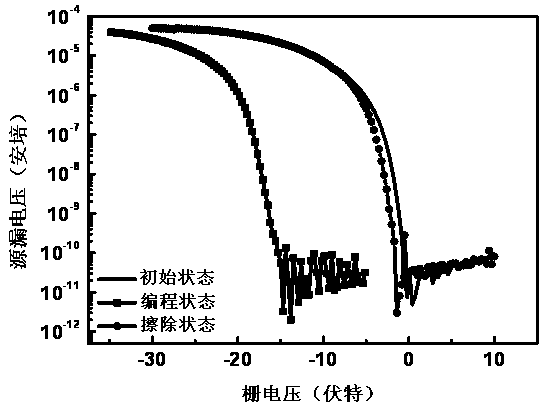

Embodiment 2

[0043] Step 1: Prepare a PbSe quantum dot solution with toluene as the solvent and a concentration of 1 mg / ml. Let it stand for 30 min to make it evenly dispersed;

[0044] Step 2: Select a highly doped silicon wafer as the substrate 6, and sequentially form a gate electrode 5 and a gate insulating layer 4 on the substrate 6. The gate electrode 5 is made of highly doped silicon, and the gate insulating layer 4 is made of silicon dioxide. The thickness of the gate insulating layer 4 is 50nm, and the substrate is made. The substrate is ultrasonically cleaned with acetone, ethanol, and deionized water for 10 minutes, and the ultrasonic frequency is 100 KHz. Then, the liquid on the substrate surface is blown dry with high-purity nitrogen. The surface of the substrate is clean, and then it is dried in an oven at 120°C;

[0045] The third step: Place the dried clean substrate in a UV ozone machine and treat it with UV ozone for 3 minutes;

[0046] The fourth step: in the air, spin-coat th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com