Preparation method of a carbon gel-loaded sulfur-lithium-sulfur battery cathode material

A lithium-sulfur battery and cathode material technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of long reaction time, high production cost and high temperature, achieve uniform distribution of sulfur element, fast cooling speed, and improve energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

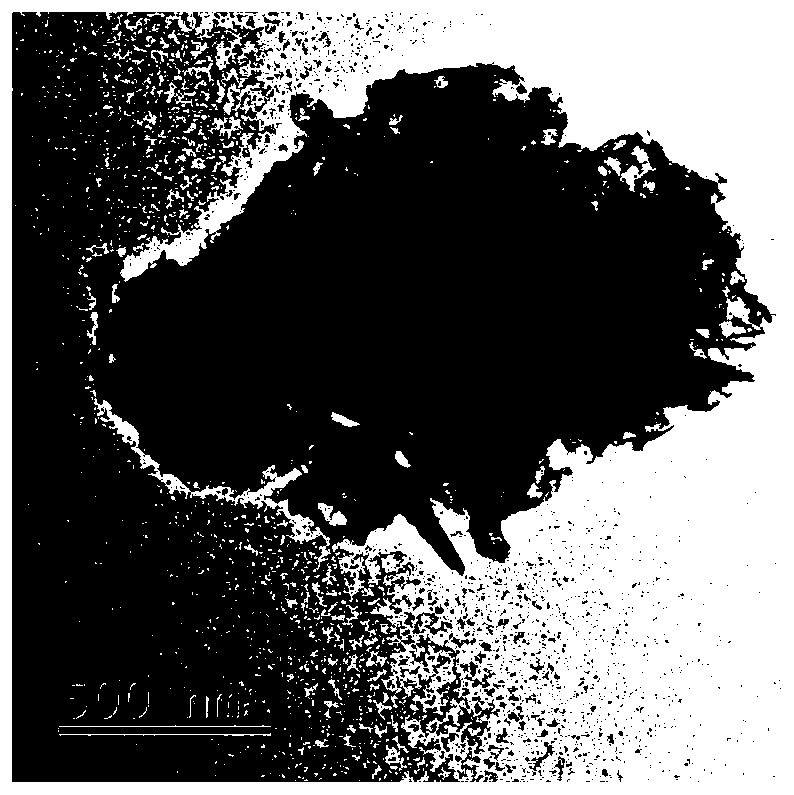

[0046] (1) Pretreatment of the carbon gel material and the container conduit used: the carbon gel material, the container and conduit used were cleaned with deionized water, and then placed in a blast drying oven for 10 hours at 80°C to remove surface moisture;

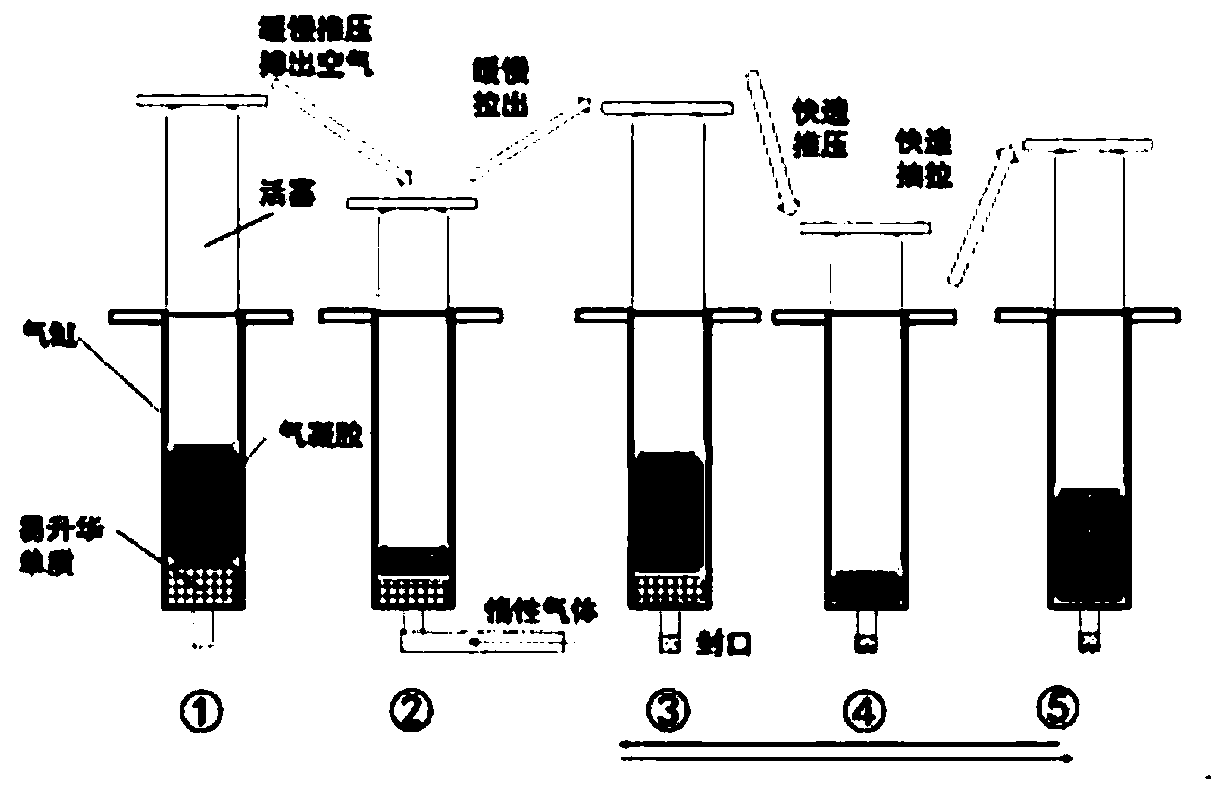

[0047] (2) Put 5g of elemental sulfur into the bottom of the piston-sealed cylindrical cylinder, stack 5g of cylindrical carbon gel material on it, and pack into the piston;

[0048] (3) Push the piston to the bottom of the cylinder, completely discharge the air in the cylinder and the carbon gel material, connect the outlet of the cylinder to nitrogen, and pull the piston to fill it with nitrogen until the compression ratio is 2;

[0049] (4) Seal the outlet of the cylinder, and quickly push the piston at a speed of 0.2m / s. The nitrogen in the cylinder will heat up due to sudden compression, causing the sulfur element to be sublimated by heat and enter the pores of the carbon gel material under the pressure of the pist...

Embodiment 2

[0053] (1) Pretreatment of the carbon gel material and the container and conduit used: Clean the carbon gel material, the container and the conduit used with deionized water and put them in a blast drying oven for 24 hours at 100°C to remove surface moisture;

[0054] (2) Put 20g of elemental sulfur into the bottom of the piston-sealed cylindrical cylinder, stack 1g of cylindrical carbon gel material on it, and pack into the piston;

[0055] (3) Push the piston to the bottom of the cylinder, completely discharge the air in the cylinder and the carbon gel, connect the outlet of the cylinder to helium, and pull the piston to fill it with helium until the compression ratio is 10;

[0056] (4) Seal the outlet of the cylinder, and quickly push the piston at a speed of 1m / s. The helium in the cylinder will heat up due to sudden compression, causing the sulfur element to be sublimated by heat, and enter the pores of the carbon gel material under the pressure of the piston. middle; ...

Embodiment 3

[0061] (1) Pretreatment of the carbon gel material and the container conduit used: the carbon gel material, the container and conduit used were cleaned with deionized water, and then placed in a blast drying oven for 18 hours at 90°C to remove surface moisture;

[0062] (2) Put 10g of elemental sulfur into the bottom of the piston-sealed cylindrical cylinder, stack 2g of cylindrical carbon gel material on it, and pack into the piston;

[0063] (3) Push the piston to the bottom of the cylinder, completely discharge the air in the cylinder and the carbon gel, connect the outlet of the cylinder to argon, and pull the piston to fill it with argon until the compression ratio is 5;

[0064] (4) Seal the outlet of the cylinder, and quickly push the piston at a speed of 1m / s. The argon in the cylinder will heat up due to sudden compression, causing the sulfur element to be sublimated by heat and enter the pores of the carbon gel material under the pressure of the piston. middle;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com