Turn-off power semiconductor device with improved centering and fixing of gate ring, and method for manufacturing same

一种功率半导体、半导体的技术,应用在半导体/固态器件制造、半导体器件、半导体/固态器件零部件等方向,能够解决晶片破裂、电气故障、橡胶环损坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

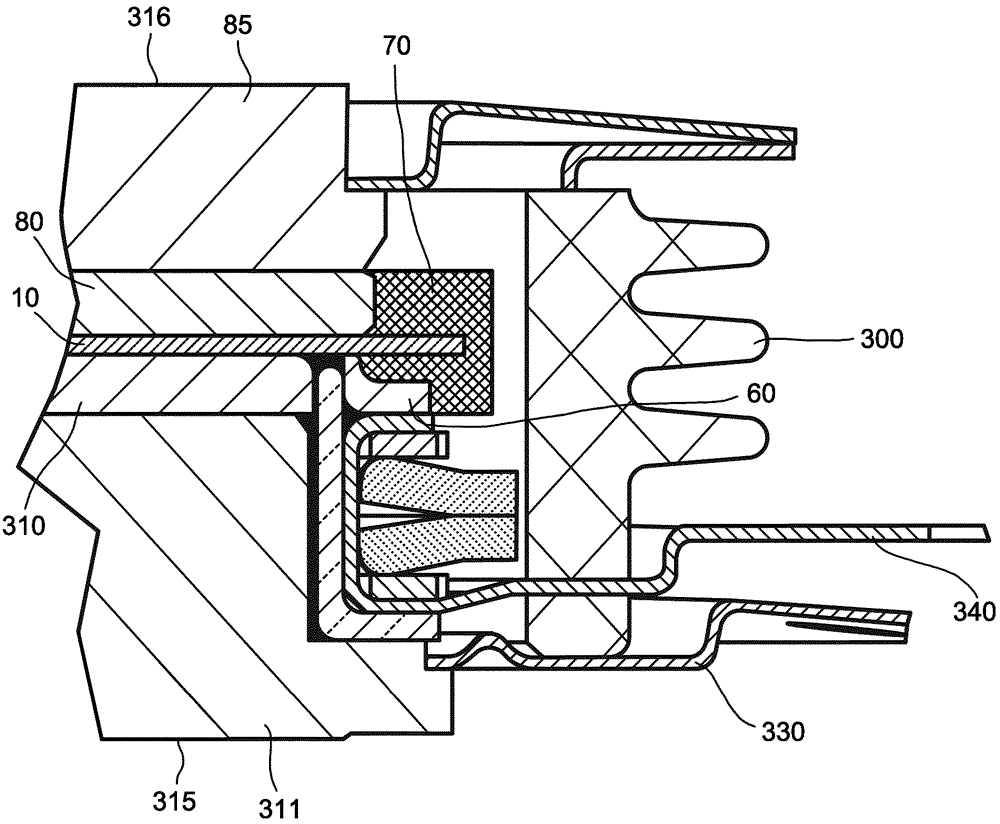

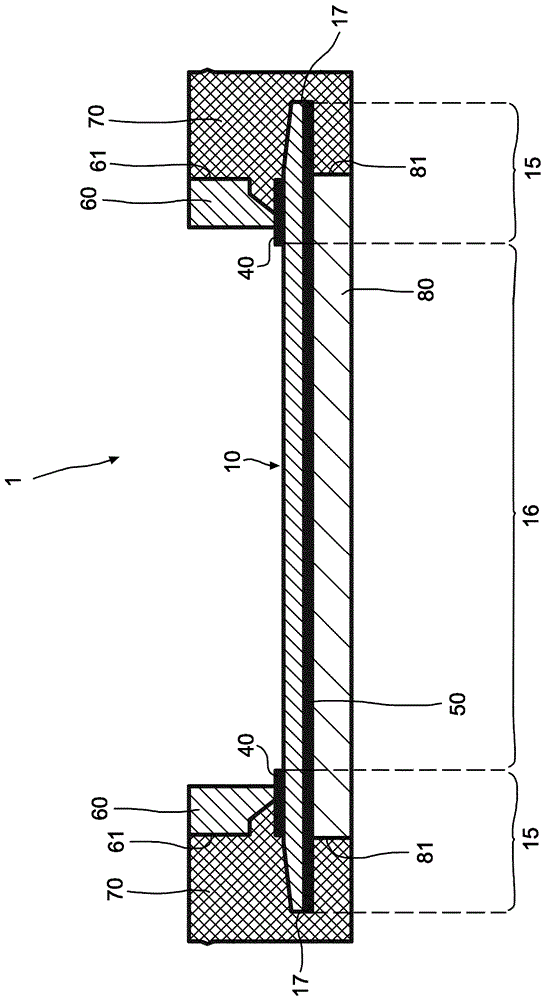

[0036] figure 1 The turn-off power semiconductor device according to the first embodiment of the invention shown in cross section is a reverse conducting integrated gate commutated thyristor (RC-IGCT) 1 comprising a wafer 10 , a conductive gate ring 60 and a rubber ring 70 . as in Figure 2A (which shows along the Figure 2BAs can best be seen in the cross-section of the wafer 10 in line AA' in ), the wafer 10 has a first main side 11 and a second main side 12, which are parallel to the first main side 11 and extend laterally. The wafer comprises an active region 16 (inner region) and a termination region (edge region) 15 surrounding the active region 16 . In the active region 16 of the wafer 10 a plurality of thyristor cells 2 and a single freewheeling diode 3 are provided between the first main side 11 and the second main side 12 .

[0037] Each thyristor cell 2 comprises, from the first main side 11 to the second main side 12 of the wafer 10, a first cathode electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com