Rotating-disk semi-automatic machine for kernel removal and peeling of litchi

A semi-automatic, turntable technology, which is used in fruit peeling devices, vegetable or fruit peeling, food science, etc. It can solve the problem that the core and peeling is not clean and hygienic, affect the development of the lychee deep processing industry, and cannot obtain lantern-shaped pulp. and other problems, to achieve the effect of easy cleaning and maintenance, less loss of pulp and juice, and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

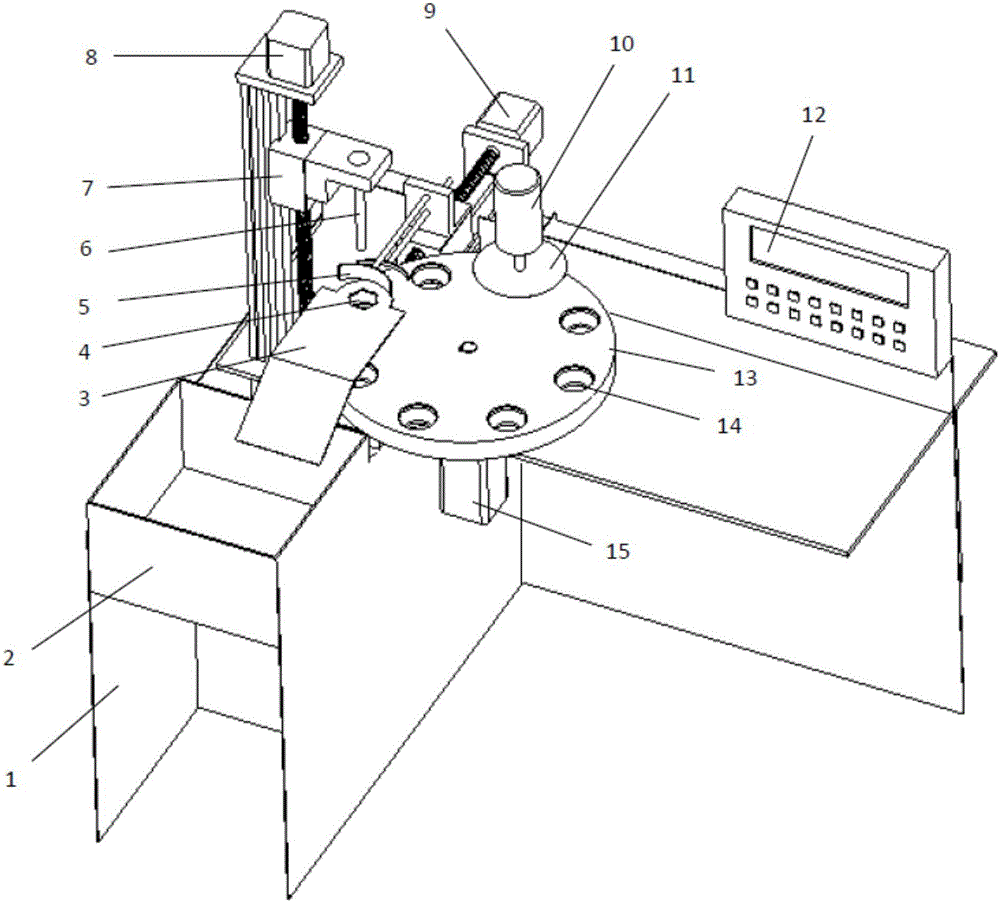

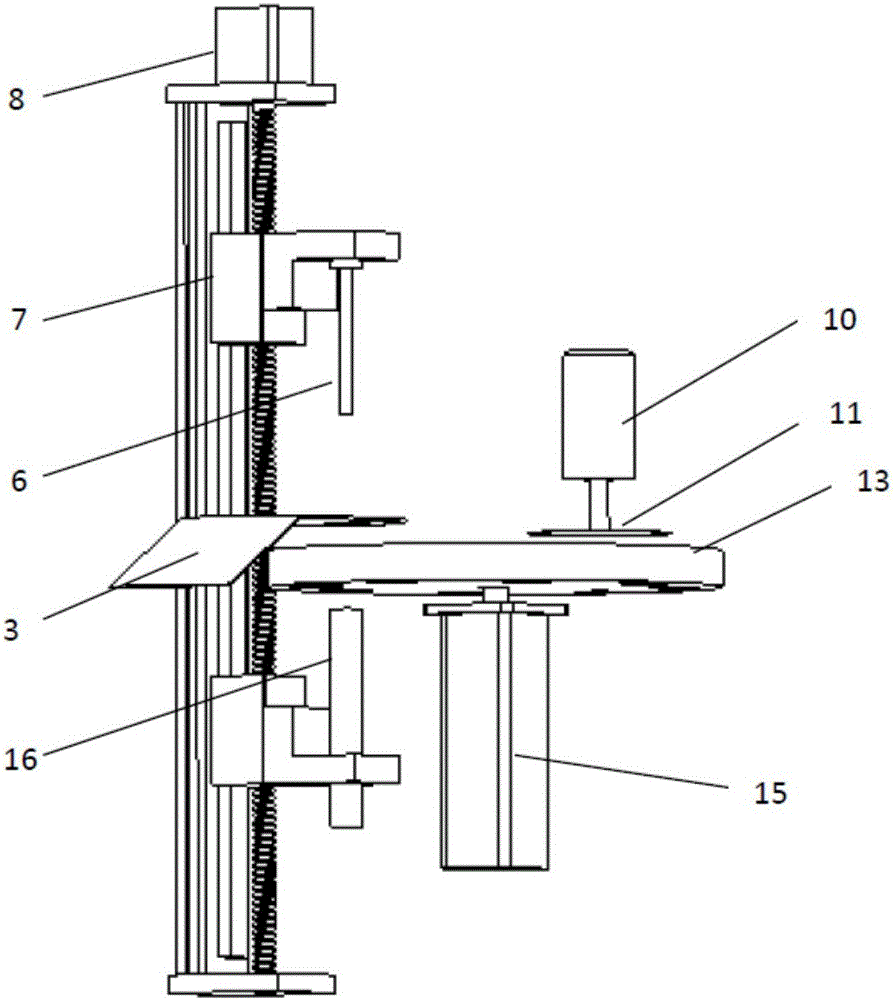

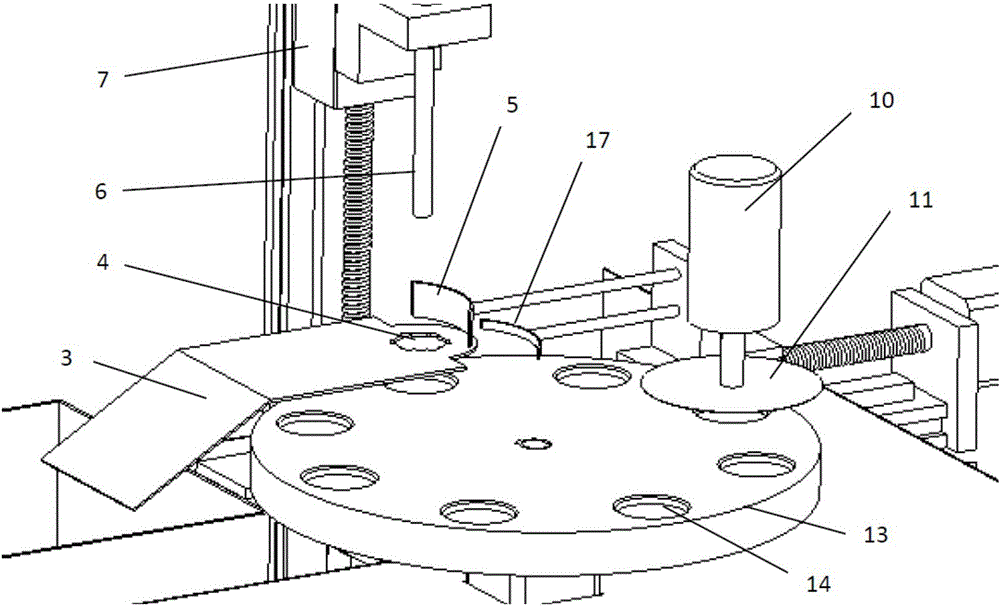

[0034] Such as figure 1 with Figure 4 As shown, the present invention discloses a turntable type semi-automatic lychee peeling and peeling machine, comprising a controller 12 and a turntable mechanism provided with a positioning hole 14 for placing litchi, and a device for cutting off fruit pedicles sequentially installed around the turntable mechanism. Pre-cut mechanism and coring and peeling mechanism. The controller 12 is electrically connected with the turntable mechanism, the pre-cut mechanism and the coring and peeling mechanism respectively, and controls them respectively and cooperates with each other. The turntable mechanism is arranged horizontally and rotates intermittently in one direction. Described pre-cutting mechanism is arranged on the pre-cutting station, is positioned at the top of positioning hole 14, litchi is placed in positioning hole 14 (fruit pedicle is upward), when passing through pre-cut mechanism, fruit pedicle is excised. Described denucleatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Opening diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com