Liquid metal mobile phone back plate and preparing method thereof

A technology of liquid metal and back plate, which is applied in the field of liquid metal mobile phone back plate and its preparation, can solve the problems of short service life, non-wear-resistant and scratch-resistant protective shell, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

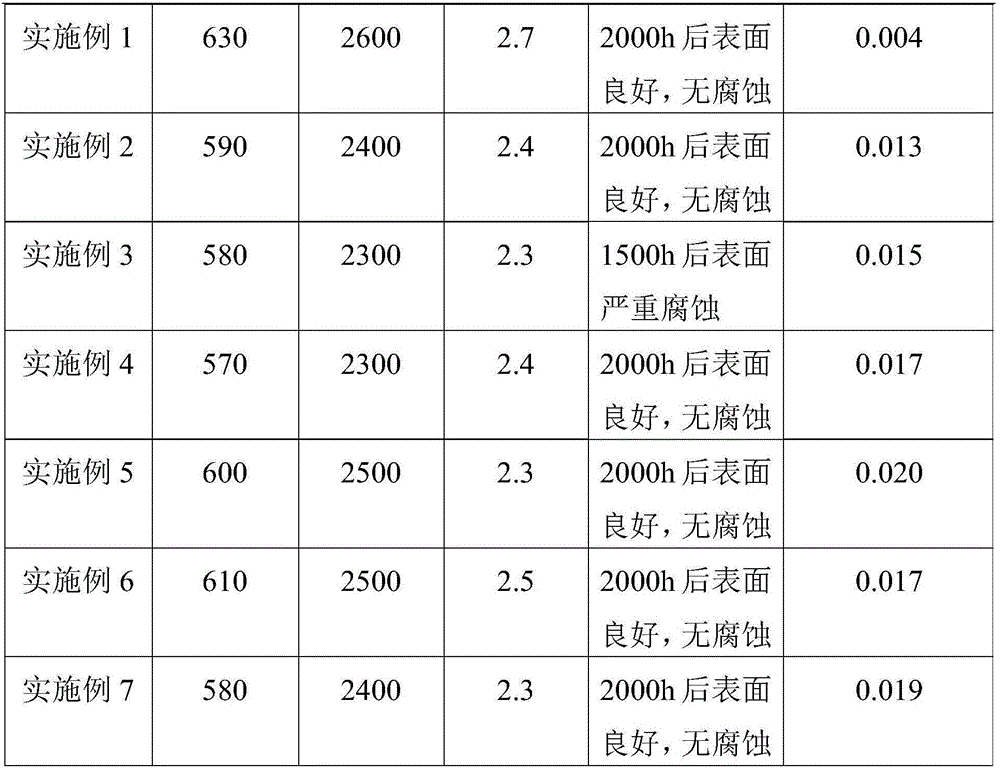

Embodiment 1

[0037] Liquid metal mobile phone backplane raw materials (parts by weight): 55 parts of Zr, 22 parts of Cu, 2 parts of Ni, 8 parts of Co, 10 parts of Al, 2.4 parts of M, and 0.6 parts of N.

[0038] The M is obtained by stirring and uniformly mixing Sn, Hf, and Y in a mass ratio of 1:1:1.

[0039] The N is obtained by uniformly stirring and mixing Pr, Yb, and Tb in a mass ratio of 1:1:1.

[0040] In a vacuum of 10 -1 Prepare the liquid metal mobile phone backplane under the protection of torr's vacuum state, specifically including the following steps:

[0041] (1) Feeding: put each raw material into the feeding device of the horizontal die-casting machine, and drop it into the melting device of the horizontal die-casting machine by the feeding device. The vacuum degree of the horizontal die-casting machine is 10 -1 torr;

[0042] (2) Melting: use induction heating to melt each raw material and form a molten soup, and the temperature of the molten soup is 1600°C;

[0043] (...

Embodiment 2

[0047] It is basically the same as in Example 1, except that the M is obtained by stirring and mixing Hf and Y in a mass ratio of 1:1. Obtain the liquid metal mobile phone back plate of embodiment 2.

Embodiment 3

[0049] It is basically the same as in Example 1, except that the M is obtained by stirring and mixing Sn and Y in a mass ratio of 1:1. Obtain the liquid metal mobile phone back plate of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com