Carrier rocket thrust vector control swing engine resonant frequency test system

A thrust vector control, launch vehicle technology, applied in the direction of frequency measurement device, etc., can solve the problems of complex engine structure design, difficult to simulate and calculate the resonance characteristics, affecting the stability of the dynamic performance of the servo mechanism rocket control system, etc., and achieve accurate results. , Test the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

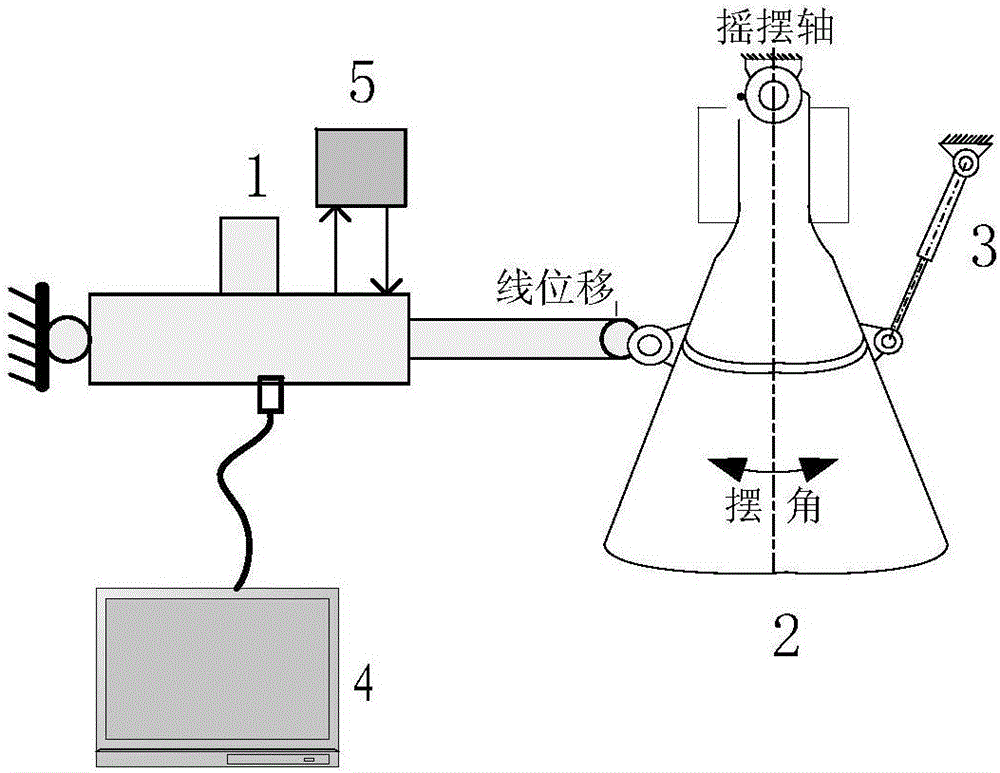

[0026] like figure 1 As shown, the system of the present invention includes a servo mechanism 1, an angular displacement sensor 3, a tester 4, and a ground energy source 5; the servo mechanism 1 is a mechanism with a built-in displacement sensor and one end is retractable, and one end of the servo mechanism 1 is fixed on the frame of the engine 2, The telescopic end is fixedly connected to the nozzle of the engine 2, the ground energy source 5 supplies power to the servo mechanism 1, the upper end of the swing part of the engine is connected through the swing shaft, one end of the angular displacement sensor 3 is installed on the frame of the engine 2, and the other end is retractable and fixedly connected On the engine nozzle, it is coplanar with the servo mechanism and passes through the same rocking center; the tester 4 issues instructions to control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com