Active polyurethane high molecular compound

A polymer compound and active technology, applied in the field of active polyurethane polymer compounds, can solve problems such as lack of reactivity and limited scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

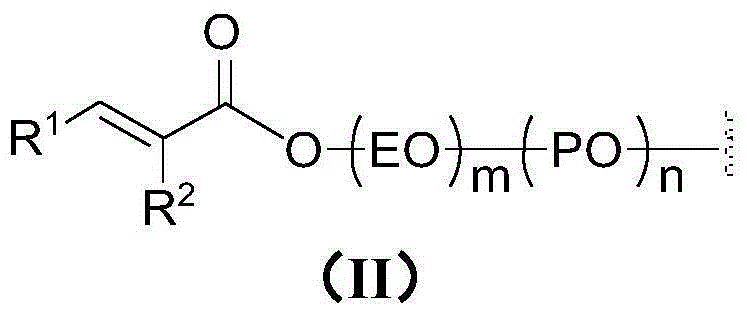

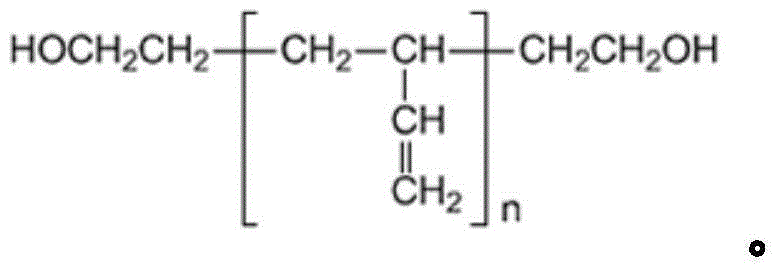

Method used

Image

Examples

Embodiment -5

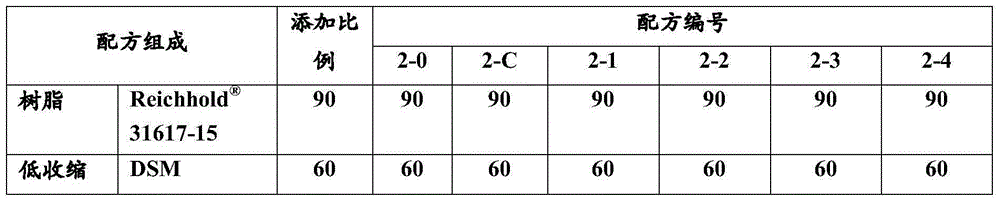

[0094] Example-5 application test

[0095] The phase separation prevention effect of the additive was tested in the following formulations

[0096]

[0097]

[0098] The commercially available product is W-972 from BYK Company of Germany, which is used to prevent phase separation.

[0099] Add additives to the resin, stir at 1000rpm for 1min to fully mix, add low-shrinkage components, and stir at 1000rpm for 2min. Immediately pour the paste into a 200ml beaker and observe the phase separation of the system.

[0100]

[0101] Where "--" indicates severe phase separation.

[0102] In the above examples, the effect of the present invention on preventing phase separation is better than or equal to that of the commercially available products.

[0103] Embodiment-6 application test

[0104] Testing Invention Product Performance in High Performance SMC Formulations

[0105] Step 1 Test the effect of preventing phase separation in the following resin paste formula

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com