Polyethylene composition and antistatic film

A technology of polyethylene and composition, applied in the field of polyethylene composition and antistatic film, can solve the problems of poor film forming property, easy film rupture and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

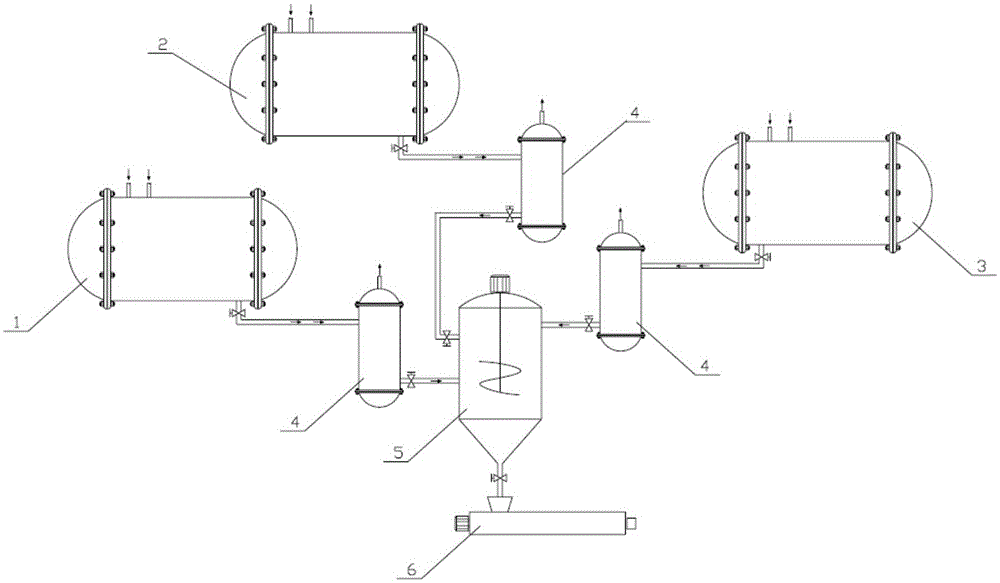

[0032] According to a preferred embodiment of the present invention, the polyethylene composition is figure 1 Prepared in the shown multi-reactor parallel device, described multi-reactor parallel device comprises first reactor 1, second reactor 2, third reactor 3, solid / liquid (gas) separator 4, homogenizer The silo 5 and the melt granulation system 6, wherein the first reactor 1, the second reactor 2 and the third reactor 3 are connected in parallel, and the number of the solid / liquid (gas) separator 4 is three One, communicated with the first reactor 1, the second reactor 2 and the third reactor 3 respectively, the component A prepared by the first reactor 1, the component B prepared by the second reactor 2 and the component B prepared by the third reactor The component C prepared by the reactor 3 is separately phase-separated in different solid / liquid (gas) separators 4, and then the phase-separated component A, component B and component C are sent to the homogenizer in pro...

Embodiment 1

[0048] This example is used to illustrate the polyethylene composition and antistatic film provided by the present invention.

[0049] The polyethylene composition provided in this embodiment contains component A, component B, component C, conductive filler and lubricant. Component A, component B and component C are all linear low density polyethylene (LLDPE) of ethylene / alpha olefin copolymerization, and all adopt identical catalyst system (metallocene catalyst system is the support prepared by CN102453124A embodiment 1 type metallocene catalyst, the same below). The properties of component A, component B, component C, conductive filler and lubricant are as follows:

[0050] Melt index MI of component A A =1.5g / 10min, density ρ A =0.913g / cm 3 , molecular weight distribution index M w / M n =3.4, the molar content of α-olefin comonomer=7.5mol%;

[0051] Melt index MI of component B B =2.1g / 10min, density ρ B =0.913g / cm 3 , molecular weight distribution index M w / M ...

Embodiment 2

[0061] This example is used to illustrate the polyethylene composition and antistatic film provided by the present invention.

[0062]The polyethylene composition provided in this embodiment contains component A, component B, component C, conductive filler and lubricant. Component A, component B and component C are all ethylene / α-olefin copolymerized linear low-density polyethylene (LLDPE), and are all prepared by using the same metallocene catalyst system. The properties of component A, component B, component C, conductive filler and lubricant are as follows:

[0063] Melt index MI of component A A =0.01g / 10min, density ρ A =0.930g / cm 3 , molecular weight distribution index M w / M n =3.0, the molar content of α-olefin comonomer=1.6mol%;

[0064] Melt index MI of component B B =10.0g / 10min, density ρ B =0.930g / cm 3 , molecular weight distribution index M w / M n =2.8, the molar content of α-olefin comonomer=1.9mol%;

[0065] Melt index MI of component C C =60g / 10mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com