A method for removing dibenzothiophene in oil by using co/kit-6 cubic mesoporous catalyst

A technology of KIT-6 and dibenzothiophene is applied in the field of removing dibenzothiophene in oil products, which can solve the problems of insufficient reaction and immiscibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

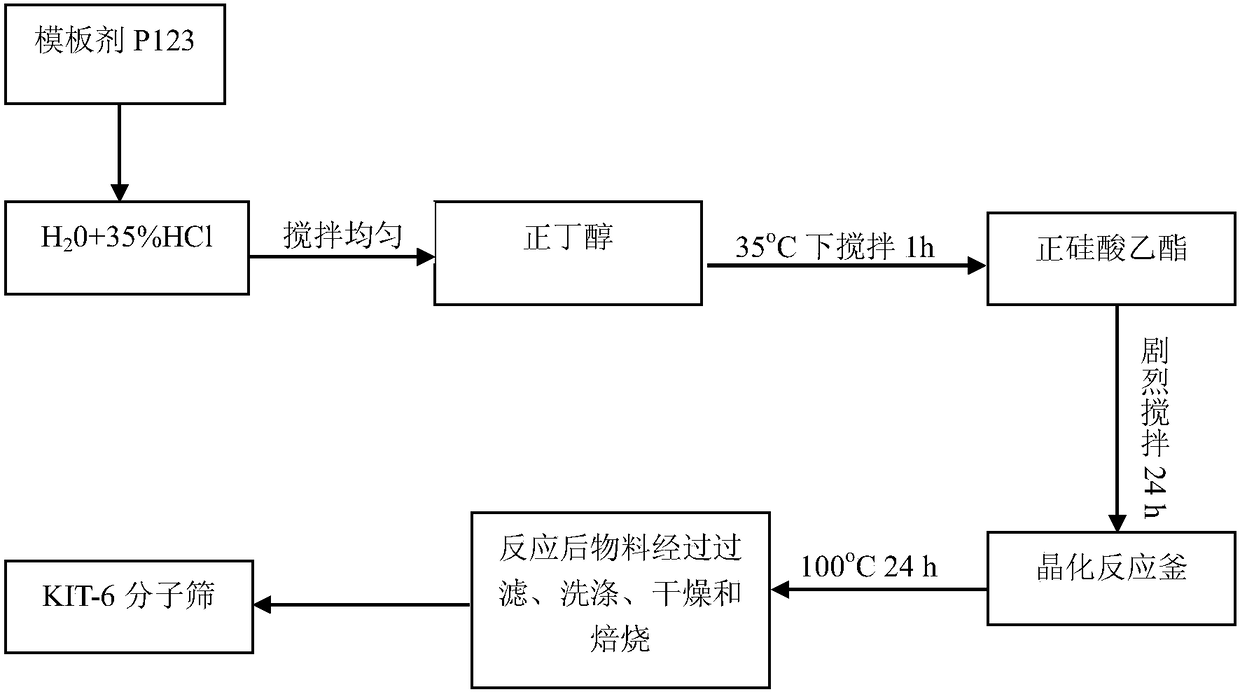

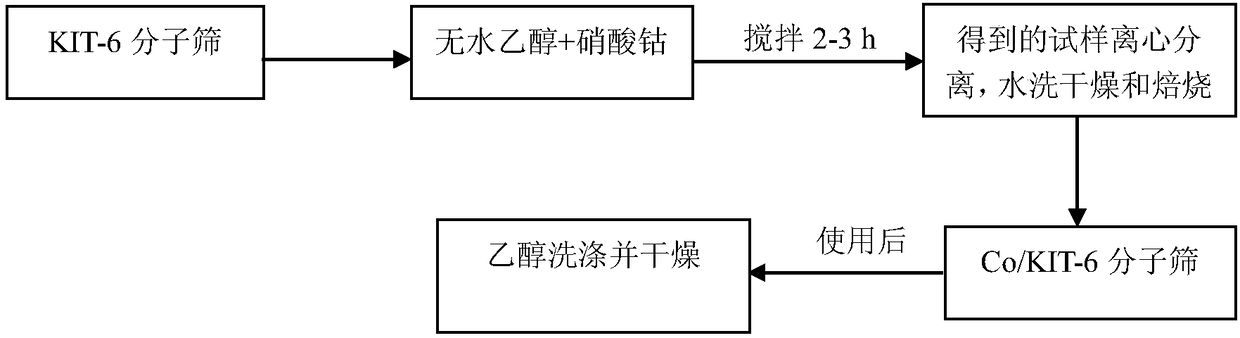

Method used

Image

Examples

Embodiment 1

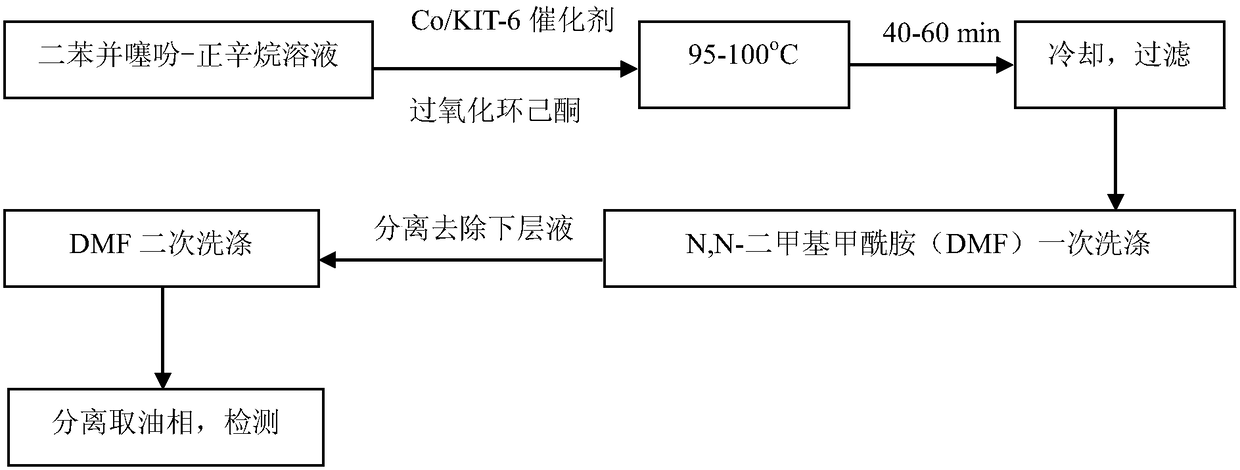

[0016] Add 5g of KIT-6 molecular sieve to 100ml of absolute ethanol, add 25ml of cobalt nitrate solution dropwise, the concentration of cobalt is 0.25g / ml, magnetically stir for 2-3h, the obtained sample is centrifuged, washed with water and heated at 60°C Dry overnight at 550 DEG C for 6 h and dry to constant weight; take 0.1 g of the catalyst prepared above, add it to 20 ml of DBT-n-octane solution with a sulfur concentration of 400 ppm, and then add a certain amount of cyclohexanone peroxide oxidant, O / S=4, react in an oil bath at 100°C for 40min, take it out and cool to room temperature, filter to obtain a clear solution, transfer it to an extraction bottle, add 10ml of N,N-dimethylformamide for extraction twice, each Every time, it must be left to stand for 10 minutes after being fully shaken, then remove the lower layer solution, take out the oil phase, and then use gas chromatography to detect its sulfur content. The sulfur content in the solution is reduced to 5.28ppm<1...

Embodiment 2

[0018] Add 5g of KIT-6 molecular sieve to 100ml of absolute ethanol, add 25ml of cobalt nitrate solution dropwise, the concentration of cobalt is 0.25g / ml, magnetically stir for 2-3h, the obtained sample is centrifuged, washed with water and heated at 60°C Dry overnight under 550 DEG C of roasting 6h and dry to constant weight; Get the catalyst 0.1g of above-mentioned preparation, join in the DBT-n-octane solution that 20ml sulfur-containing concentration is 400ppm, add a certain amount of cyclohexanone peroxide oxidant ( O / S=6), react in an oil bath at 100°C for 40 minutes; take it out and cool to room temperature, filter to obtain a clear solution, transfer it to an extraction bottle, add 10ml of N,N-dimethylformamide to extract twice, Each time, it should be left to stand for 10 minutes after being fully shaken, then remove the lower layer solution, take out the oil phase, and then use gas chromatography to detect its sulfur content. The rate reaches 98.71%.

Embodiment 3

[0020] Add 5g of KIT-6 molecular sieve to 100ml of absolute ethanol, add 25ml of cobalt nitrate solution dropwise, the concentration of cobalt is 0.25g / ml, magnetically stir for 2-3h, the obtained sample is centrifuged, washed with water and heated at 60°C Dry overnight at 550°C for 6 hours until constant weight. Get 0.1g of the catalyst prepared above, add it into 20ml of DBT-n-octane solution with a sulfur concentration of 400ppm, then add a certain amount of cyclohexanone peroxide oxidant, O / S=4, in an oil bath at 100°C React in medium for 50min. Take it out and cool it to room temperature, filter to obtain a clear solution, transfer it to an extraction bottle, add 10ml of N,N-dimethylformamide for extraction twice, each time shake fully and let it stand for 10min, then remove the lower layer solution The oil phase is taken out, and its sulfur content is detected by gas chromatography, and the sulfur content in the solution is reduced to 4.12ppm<10ppm, which meets the Euro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com