Removal and resourceful treatment method for hydrogen sulfide in natural gas

A treatment method and technology for hydrogen sulfide, which are applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of large area of absorption tower and desorption tower, loss of alcohol amine solvent, equipment corrosion, etc., to achieve resource utilization, reduce The effect of occupying area and saving land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The volume content of hydrogen sulfide in a certain natural gas is 10%.

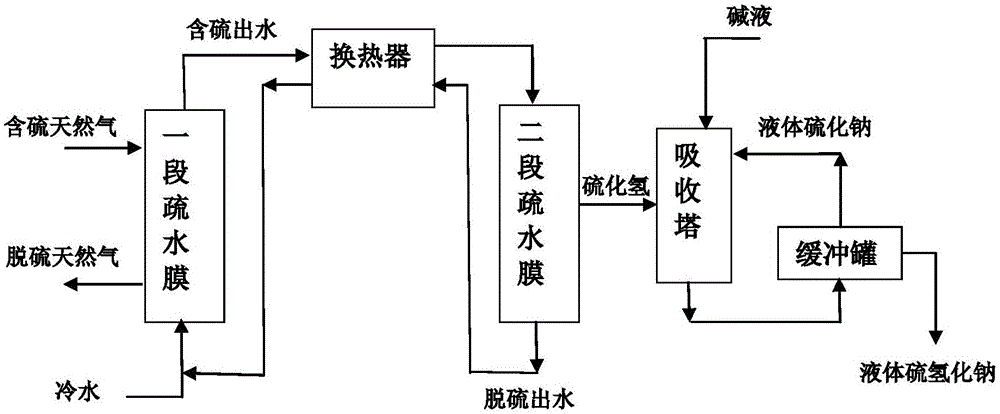

[0062] The treatment steps are as follows: under the pressure of 0.1MPa, press natural gas containing hydrogen sulfide into the shell side of a section of polypropylene hollow fiber hydrophobic membrane module with a pore size of 0.2μm, and use cold water at a temperature of 5°C as the absorbing liquid to make it in the hollow The tube side of the fiber hydrophobic membrane module is the reverse flow of the hollow fiber membrane hole and the natural gas containing hydrogen sulfide. The hydrogen sulfide in the natural gas enters the water absorption liquid through the membrane. The flow rate of the cold water in the tube side is 0.5m / s. After the sulfur-containing effluent of the hydrophobic membrane is heat-exchanged by the heat exchanger, it is heated to 45°C by a pipeline heater, and then flows into the membrane pores of the two-stage polypropylene hollow fiber hydrophobic membrane with a pore si...

Embodiment 2

[0067] The volume content of hydrogen sulfide in a certain natural gas is 12%.

[0068] The treatment steps are as follows: under the pressure of 0.2MPa, press natural gas containing hydrogen sulfide into the shell side of a section of polypropylene hollow fiber hydrophobic membrane module with a pore size of 0.15μm, and use cold water at a temperature of 15°C as the absorbing liquid to make it in the hollow The tube side of the fiber hydrophobic membrane module is the reverse flow of the hollow fiber membrane hole and the natural gas containing hydrogen sulfide. The hydrogen sulfide in the natural gas enters the water absorption liquid through the membrane. The cold water flow rate in the tube side is 1.0m / s. After the sulfur-containing effluent of the hydrophobic membrane is heat-exchanged by the heat exchanger, it is heated to 43°C by a pipeline heater, and then flows into the membrane pores of the two-stage polypropylene hollow fiber hydrophobic membrane with a pore size of...

Embodiment 3

[0073] The volume content of hydrogen sulfide in a certain natural gas is 15%.

[0074] The treatment steps are as follows: under the pressure of 0.3 MPa, the natural gas containing hydrogen sulfide is pressed into the shell side of a section of polypropylene hollow fiber hydrophobic membrane module with a pore size of 0.1 μm, and cold water at a temperature of 10 ° C is used as the absorption liquid to make it in the hollow The tube side of the fiber hydrophobic membrane module is the reverse flow of the hollow fiber membrane hole and the natural gas containing hydrogen sulfide. The hydrogen sulfide in the natural gas passes through the membrane and enters the water absorption liquid. The cold water flow rate in the tube side is 0.7m / s. The sulfur-containing effluent from the hydrophobic membrane is heated to 40°C by a pipeline heater after being heat-exchanged by a heat exchanger, and then flows into the membrane pores of the two-stage polypropylene hollow fiber hydrophobic m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap