Laser repair technology for centring roller bed

A technology of laser repairing and centering roll, which is applied in the field of laser repair, can solve problems such as lack of good wear resistance, inability to complete center roll replacement, and limited precision, and achieve low production cost, high cladding efficiency, and good long-lasting strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 A large factory centered the roller table.

[0026] The basic situation of the roller table.

[0027] Specification: Φ310×100mm; Weight: 500kg / piece; Material: 35# cast steel.

[0028] Working conditions: Conveying billets and rolled rails, billet temperature is 1050°C, roller table is 150--200°C under normal conditions, contact surface temperature can reach 500--600°C, and the roller body is naturally cooled.

[0029] Laser cladding metal powder: Cr: 15%, Mo: 5%, W: 10%, Ti: 3%, Ta: 2%, W: 2%, Co balance.

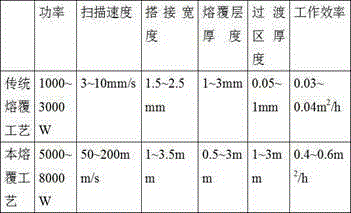

[0030] Cladding process parameters: power: 5000-8000W, scanning speed: 160mm / s, lap spacing: 2.5mm, cladding layer thickness: 1.5 mm, spot diameter: 10 mm.

[0031] After laser cladding, the centering roller has been on-line for 30 months, and its service life is more than 30 times that of the original new product, creating great economic benefits for users.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com