Turbofan engine and fan blade thereof

A turbofan and fan blade technology, which is applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., can solve the problems of desoldering of welding seams, increasing the quality of blades, and damage of blades, so as to improve impact resistance and increase damping effect, the effect of increasing path length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiment of the present invention describes a fan blade of a turbofan engine, the ability of the blade to resist the impact of foreign objects is improved, and the quality does not need to be increased, the shape of the blade does not need to be changed, and the processing technology is easy to realize.

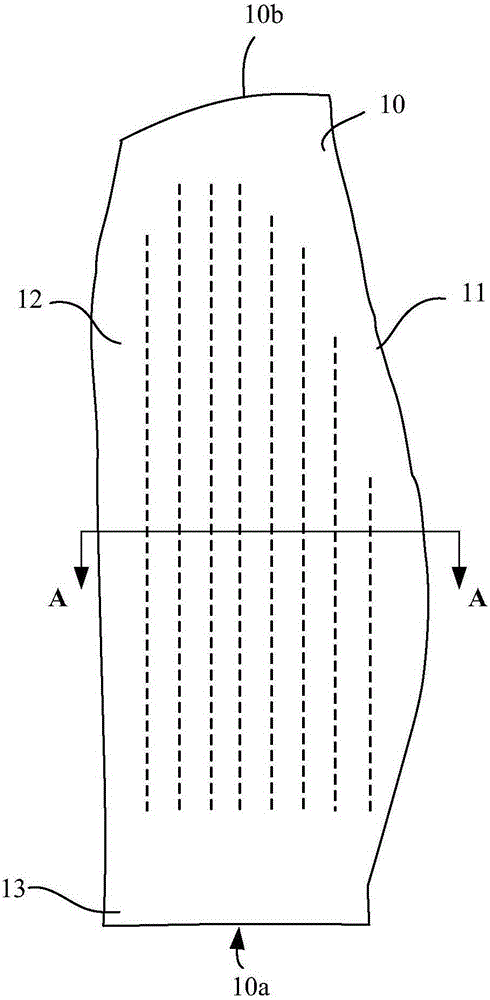

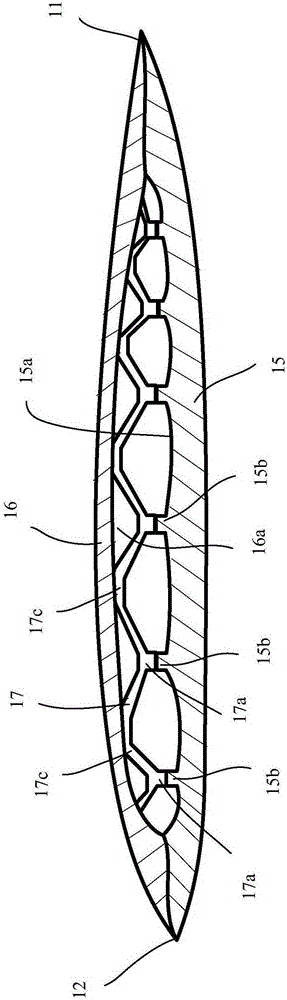

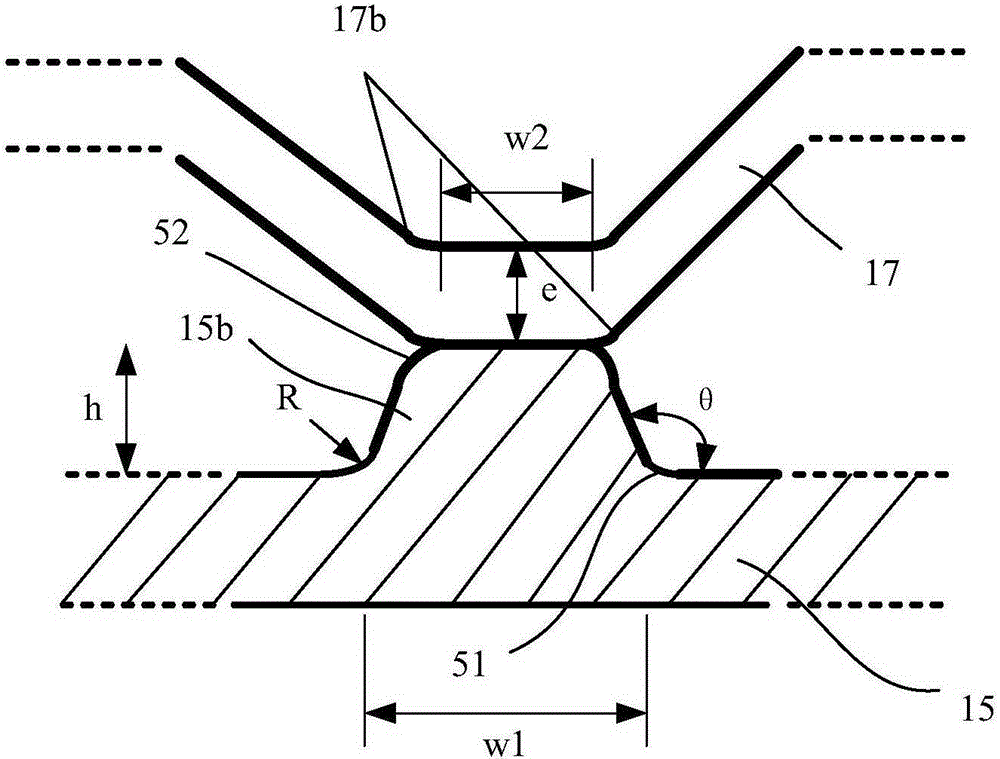

[0027] figure 1 An outline view of a fan blade of a turbofan engine according to an embodiment of the present invention is shown. figure 2 A-A sectional view showing a fan blade of a turbofan engine according to an embodiment of the present invention. refer to figure 1 and figure 2 As shown, the blade 10 can be divided into a leading edge 11 , a trailing edge 12 and a tenon 13 . The entire blade 10 is a hollow structure, including a pressure side wall plate 15 , a suction side wall plate 16 , and a core plate structure 17 . The pressure side wall plate 15 and the suction side wall plate 16 are combined to form a cavity 18 , and the core plate structure 17 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com