Making method of chilled meat roll

A production method and a technology for chilling fresh meat, applied in the field of mutton processing, can solve the problems of uneven appearance, uneven proportion of fat and lean, uneven distribution, etc., and achieve the effects of not easy to spread, tight meat, and not easy to air-dry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

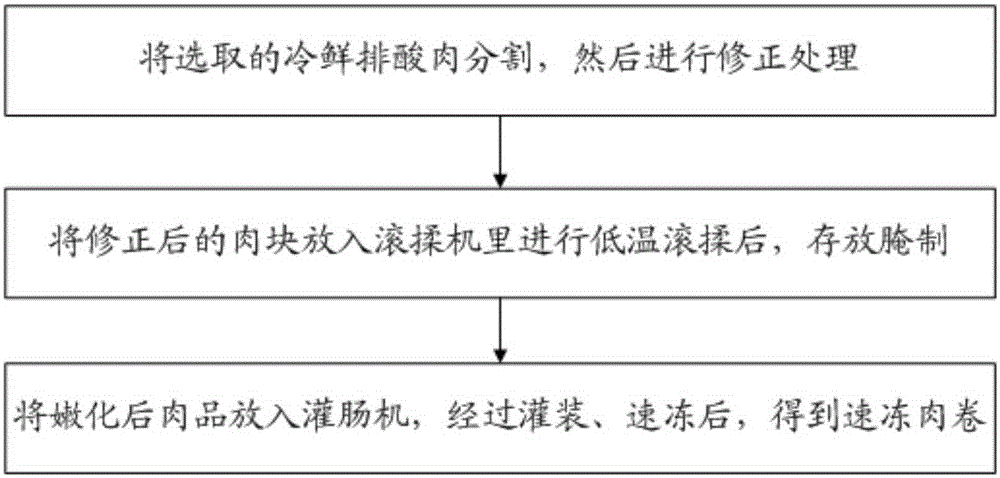

[0026] refer to figure 1 , the preparation method of cold fresh meat roll described in the present embodiment, this method realizes according to following steps:

[0027] S1, raw material pretreatment, the selected chilled fresh meat is divided into meat pieces with a size of 10cm×10cm; the meat pieces are corrected to remove blood stains, feces, lymph, broken bones, and tendons;

[0028] S2, tenderization treatment, put the corrected meat pieces into the tumbler for low-temperature tumbling and marinating for 5 minutes, and then complete the tenderization;

[0029] S3, filling, put the tenderized meat into the sausage filling machine, after filling and quick-freezing, quick-frozen meat rolls are obtained.

[0030] A more detailed explanation:

[0031] (1) In step S1, the chilled freshly soured meat selected includes chilled freshly soured mutton, cold freshly soured beef and cold freshly soured pork. Cold fresh and sour meat, with qualified sensory, physical, chemical and ...

Embodiment 2

[0041] The preparation method of cold fresh meat roll described in the present embodiment, this method realizes according to the following steps:

[0042] S1, raw material pretreatment, the selected chilled fresh meat is divided into meat pieces with a size of 8cm×8cm; the meat pieces are corrected to remove blood stains, feces, lymph, broken bones, and tendons;

[0043] S2, tenderization treatment, put the corrected meat pieces into the tumbler for low-temperature tumbling and marinating for 4 minutes, and then complete the tenderization;

[0044] S3, filling, put the tenderized meat into the sausage filling machine, after filling and quick-freezing, quick-frozen meat rolls are obtained.

[0045] In this embodiment, the temperature control condition in the process of making the chilled fresh meat roll is: the temperature is 10°C. The cold fresh and sour meat is cold fresh and sour mutton, and the weight ratio of lean meat and fat in the cold and fresh sour meat is 90:10. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com