A Separation Method of Polymer Materials Based on Magnetic-Archimedes Principle

A polymer material and separation method technology, applied in the field of polymer material separation, can solve problems such as difficult to accurately separate different materials, difficult to achieve complete separation, high cost, etc., to achieve easy observation, simple process, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the present invention more clearly understood, the present invention will be further described below according to specific examples and accompanying drawings of the present invention.

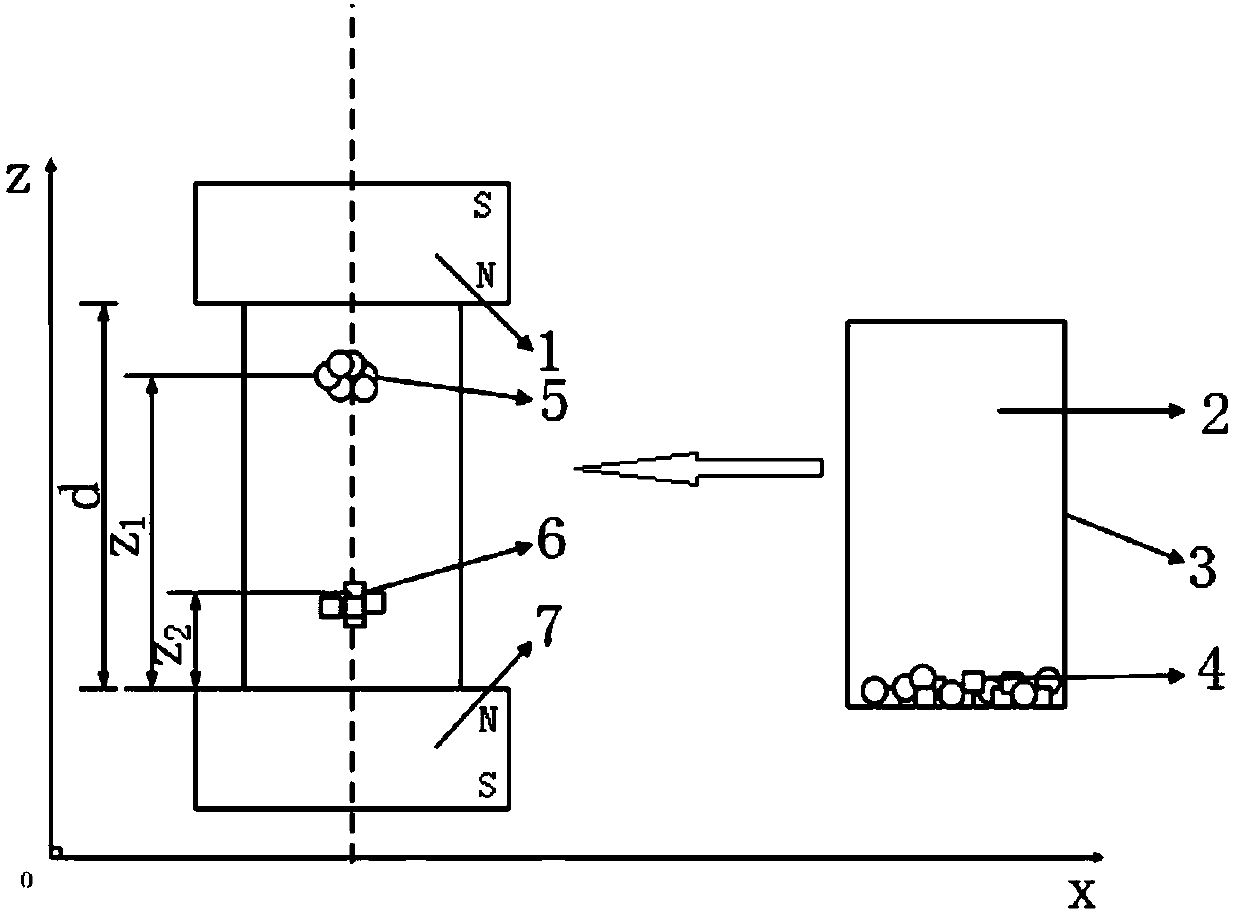

[0050] Such as figure 1 Shown is the schematic diagram of the magnetic Archimedes separation method of the present invention, including magnet 1, magnet 7, medium solution 2, medium solution container 3, mixed sample 4, sample 5 with smaller density after separation, density after separation Larger sample 6. The container 3 is required to be transparent and easy to observe the state of the sample. The distance between magnet 1 and magnet 7 is d. The suspension heights of different samples are z 1 and z 2 .

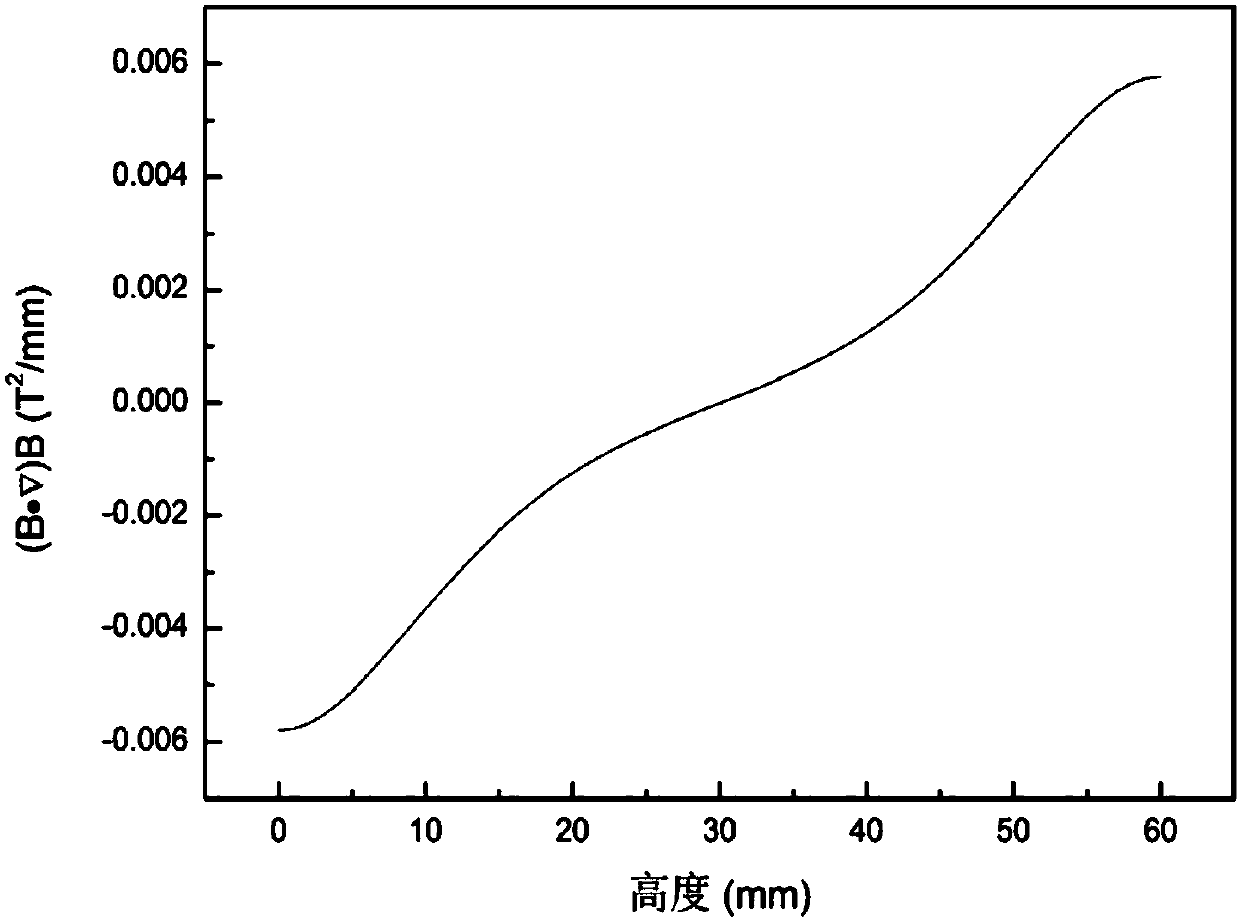

[0051]In this embodiment, magnet 1 and magnet 7 are square magnets with a length of 50mm*width of 50mm*height of 25mm, and magnets with a magnetic induction intensity of 0.425T on the center surface, which are formed by facing opposite poles at a distance of 60m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com