Low-yield-ratio high-strength pipeline steel production method

A technology of high-strength pipeline steel and production method, applied in the field of metal rolling, can solve the problems of high-strength and low-yield ratio, etc., and achieve the effects of good toughness, excellent range of yield-strength ratio, and huge social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

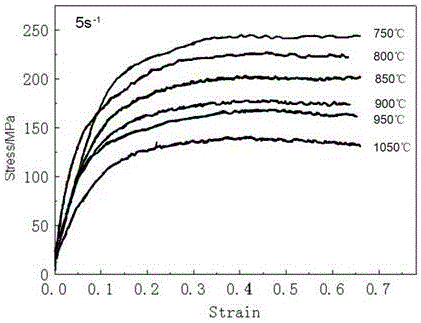

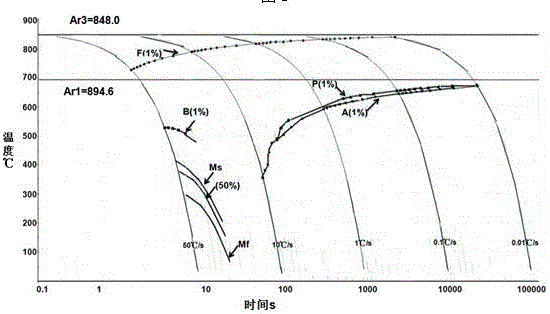

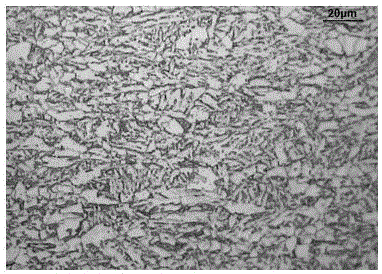

[0032] Example 1: Purified molten steel is obtained through smelting, and then cast into slabs through continuous casting machines. The composition weight percentages are: C: 0.03%, Si: 0.025%, Mn: 1.50%, P: 0.0018%, S : 0.006%, Als: 0.015%, Nb: 0.055%, Ti: 0.030%, Cr: 0.20%; Pcm: 0.13%; heat the billet to 1100°C and keep it for 320min; The pressure is 22Mpa, and the furnace oxide scale on the surface is completely removed; then rolling in the austenite recrystallization zone in the first rolling process, the starting rolling temperature is 1020°C, after the slab widening rolling is completed, four passes are used for elongation rolling In the first rolling, the pass reduction rates are 16%, 18%, 18%, and 25%, respectively, and the cumulative effective reduction rate is 77%. The temperature range of the second rolling start rolling temperature is 780°C. The pass reduction rates are 13%, 15%, 17%, and 10% respectively; the cooling temperature is 670°C, the DQ cooling section co...

Embodiment 2

[0034] Example 2: Purified molten steel is obtained through smelting, and then continuously cast into a slab through a continuous casting machine. The composition weight percentages are: C: 0.05%, Si: 0.06%, Mn: 1.61%, P: 0.013%, S : 0.005%, Als: 0.025%, Nb: 0.059, Ti: 0.020%, Cr: 0.26%; Pcm: 0.15%; heat the billet to 1130°C and keep it for 340min; to 26Mpa, thoroughly remove the furnace oxide scale on the surface; then carry out rolling in the austenite recrystallization zone in the first rolling process, the starting rolling temperature is 1050°C, and after the slab widening rolling is completed, four passes are used for elongation rolling Rolling, the pass reduction rate is 16%, 17%, 19%, 20% respectively, the cumulative effective reduction rate is 72%, the starting temperature of the austenite non-recrystallized zone in the second rolling pass is 795 ° C, four passes are adopted rolling, the pass reduction rates were 12%, 14%, 16%, and 10%. The starting cooling temperatur...

Embodiment 3

[0036] Example 3: Purified molten steel is obtained by smelting, and then cast into slabs through continuous casting machines. The composition weight percentages are: C: 0.07%, Si: 0.08%, Mn: 1.70%, P: 0.025%, S : ≤0.007%, Als: 0.045%, Nb: 0.070%, Ti: 0.010%, Cr: 0.30%; Pcm: 0.18%; heat the slab to 1150°C and keep it for 360min; turn on all the high-pressure water for descaling and descaling The water pressure is 30Mpa, and the surface furnace scale is completely removed; then the rolling in the austenite recrystallization zone in the first rolling process is carried out, and the starting rolling temperature is 1080°C. Pass rolling, the pass reduction rate is 17%, 18%, 19%, 22%, the cumulative effective reduction rate is 76%, and the rolling temperature range of the austenite non-recrystallized zone in the second rolling pass is 810°C , using four-pass rolling, the pass reduction rate is 12%, 15%, 15%, 10%, respectively, the cooling temperature is 690 °C, and the DQ cooling se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com