No commutation zone and in-phase traction power supply system for electrified railway

A technology for electrified railways and traction networks, which is applied to power lines, transportation and packaging, and vehicle components, and can solve problems affecting transportation capacity, high electricity charges for electrified railways, and blocked train power supply, so as to improve safety, transportation efficiency, and convenience The effect of train operation and accelerated construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

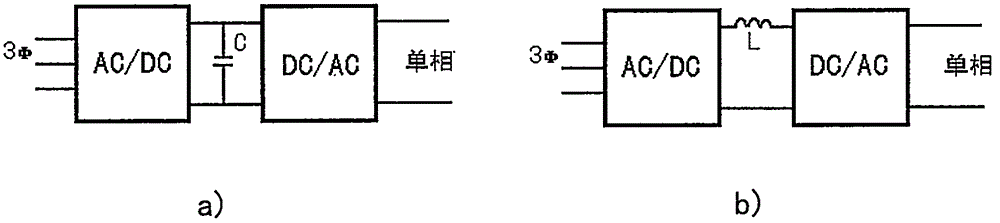

[0025] To change the balanced three-phase power into a single-phase power supply, the simplest traditional method is to fully rectify the balanced three-phase power into direct current, and then pass through a DC / AC inverter to convert the direct current into single-phase alternating current in full. This structure is called a basic 3-phase to 1-phase converter circuit.

[0026] figure 1 It is a traditional basic 3-phase to 1-phase electronic converter circuit.

[0027] DC / AC inverters are divided into voltage source inverters and current source inverters. The former has higher efficiency and better voltage stability, while the latter has good current limiting characteristics and high safety.

[0028] figure 1 a) is a DC / AC voltage source inverter, and there is a parallel capacitor C in the DC circuit. figure 1 b) is a DC / AC current source inverter, and an inductor L is connected in series in the DC circuit.

[0029] The rectifier and inverter are bidirectional, which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com