Functional plant aromatic antibacterial cellulose fiber and preparation method thereof

A cellulose fiber and functional technology, applied in the field of functional cellulose fibers, can solve the problems of not introducing the preparation process, and the functional aromaticity of the prepared fibers cannot be known, and achieves excellent thermal insulation performance, good antibacterial performance, and long release time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

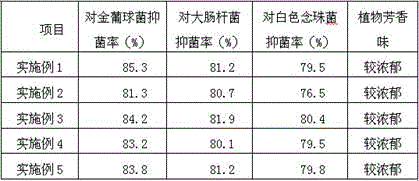

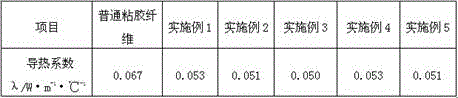

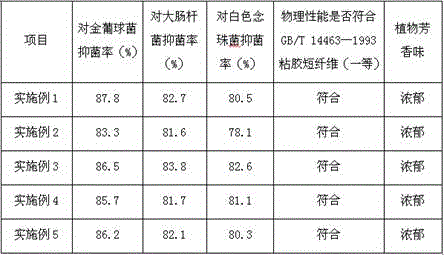

Examples

Embodiment 1

[0048] Embodiment 1 A kind of functional plant fragrance, antibacterial cellulose fiber and preparation method thereof, its preparation method comprises the following steps:

[0049] Step 1 Preparation of primary aromatic microcapsules of lavender essential oil

[0050] Add lavender essential oil to distilled water containing 1.5% (accounting for the total weight of lavender essential oil and acrylonitrile monomer) of Tween-80 emulsifier, stir well to form an emulsified solution; then weigh acrylonitrile monomer and add it to the above emulsified solution , wherein the weight ratio of essential oil lavender essential oil to polyacrylonitrile monomer is 1.0:1.0, continue to emulsify and disperse for 10 minutes to obtain a mixed emulsified solution; at 85°C, add azobisisobutyronitrile dropwise to the stirred emulsified solution to trigger Agent, polymerize acrylonitrile monomer into polyacrylonitrile and coat lavender essential oil to make microcapsules, then wash with ethanol a...

Embodiment 2

[0059] A functional plant aromatic, antibacterial cellulose fiber and a preparation method thereof, the preparation method comprising the following steps:

[0060] Step 1 Preparation of primary aromatic microcapsules of tea tree oil

[0061] Add tea tree oil to distilled water containing 1.2% (accounting for the total weight of tea tree oil and acrylonitrile monomer) of Tween-80 emulsifier, stir well to form an emulsified solution; then weigh acrylonitrile monomer and add it to the above emulsified solution , wherein the weight ratio of tea tree oil to polyacrylonitrile monomer is 1.0:1.2, continue to emulsify and disperse for 14min to obtain a mixed emulsified solution; at 76°C, add azobisisobutyronitrile initiator dropwise to the stirred emulsified solution , the acrylonitrile monomer is polymerized into polyacrylonitrile and coated with tea tree oil to make microcapsules, then washed with ethanol and distilled water, filtered and dried by suction to obtain primary aromatic ...

Embodiment 3

[0069] Embodiment 3 A kind of functional plant fragrance, antibacterial cellulose fiber and its preparation method, its preparation method comprises the following steps:

[0070] Step 1 Preparation of primary aromatic microcapsules of cinnamon essential oil

[0071] Add cinnamon essential oil to distilled water containing 1.0% (accounting for the total weight of cinnamon essential oil and acrylonitrile monomer) of Tween-80 emulsifier, stir well to form an emulsified solution; then weigh acrylonitrile monomer and add it to the above emulsified solution , wherein the weight ratio of cinnamon essential oil to polyacrylonitrile monomer is 1.0:1.5, continue to emulsify and disperse for 19 minutes to obtain a mixed emulsified solution; at 65°C, add the azobisisobutyronitrile initiator dropwise to the stirred emulsified solution , the acrylonitrile monomer is polymerized into polyacrylonitrile and coated with cinnamon essential oil to make microcapsules, then washed with ethanol and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com