Prefabricated outer wallboard and assembling method thereof

An external wall panel and pre-embedded technology, which is applied to walls, building materials, building components, etc., can solve problems such as the inconsistency of the installation method of the external wall panel with the design calculation model, the difficulty of the installation and adjustment of the external wall panel, and the water seepage of the external wall panel. , to improve the overall accuracy and construction efficiency, light weight, good sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the content of the present invention more obvious and understandable, further description will be made below in conjunction with the accompanying drawings and specific embodiments.

[0029] The technical content, features and effects of the present invention can be clearly presented in the detailed description of the preferred embodiments with reference to the drawings below. Through the description of the specific implementation, the present invention can be understood more deeply and specifically, but the accompanying drawings are only for reference and description, and are not intended to limit the present invention.

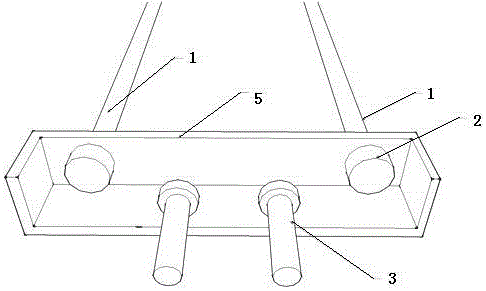

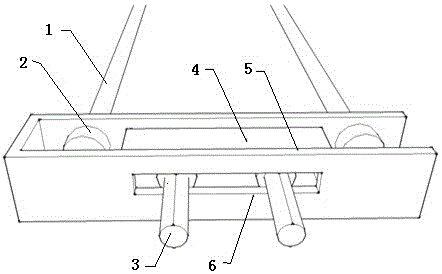

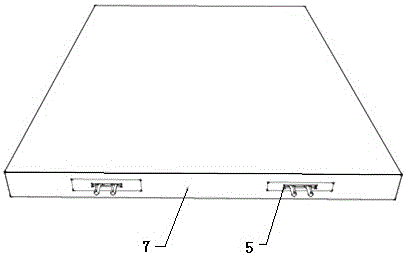

[0030] Such as Figure 1-5 As shown, a prefabricated exterior wall panel is provided with anchor rods (1), threaded anchor caps (2), sliding bolts (3), bolt limit boxes (4), embedded boxes ( 5), living tank (6), aerated concrete filling wall (7), installation column (8), embedded connector in column (9), nut hole (10), nut inner conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com