Large suspension kiln and production process thereof

A large-scale, cyclone separator technology, applied in the field of suspension roasting kiln, can solve the problems of reduced separation efficiency, increased resistance loss, system energy waste, etc., to achieve reduced structure size, low system resistance, and low temperature of kiln materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

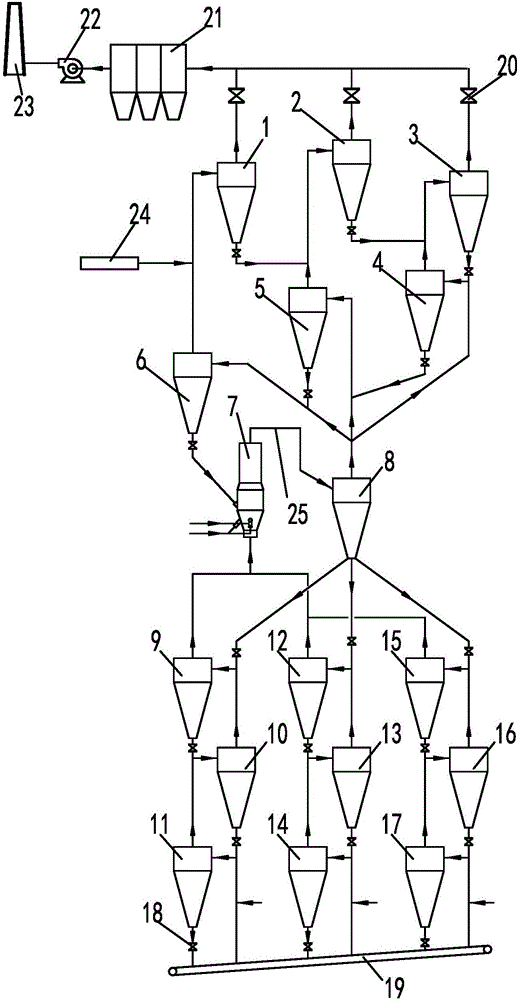

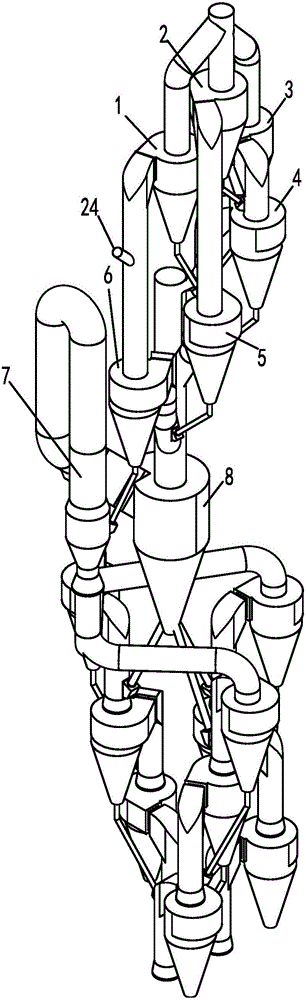

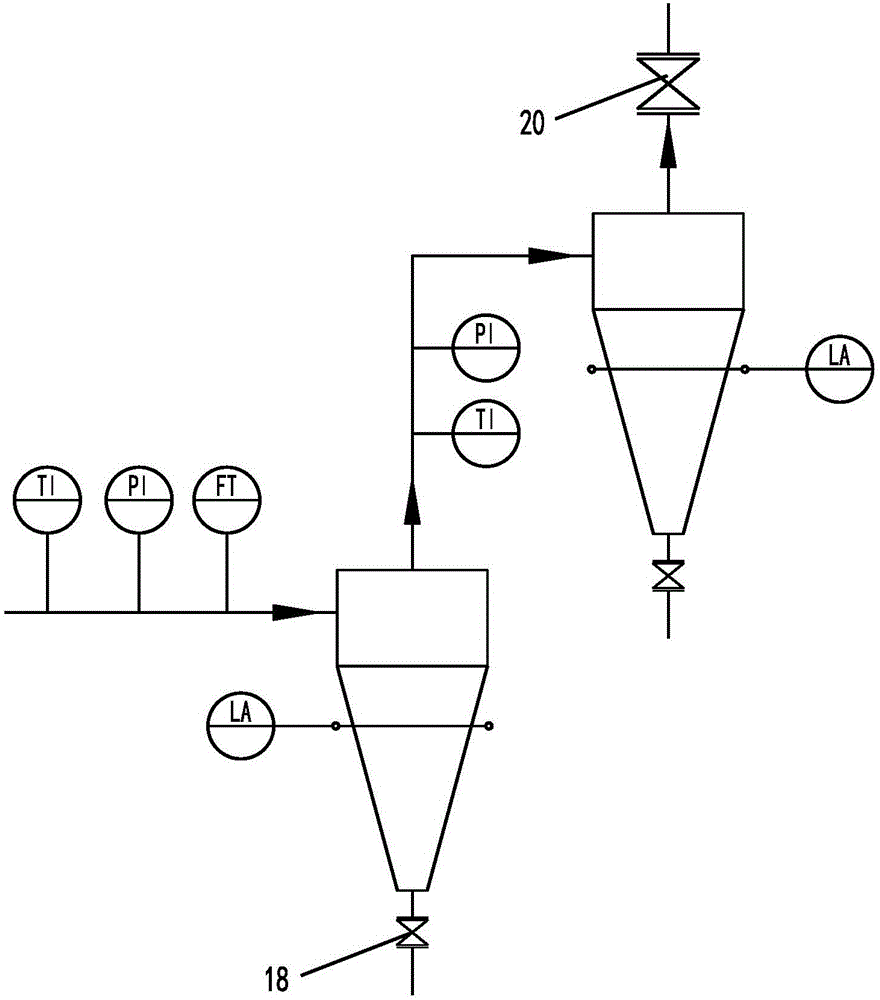

[0028] Such as figure 1 , figure 2 As shown, a large-scale suspension kiln of the present invention is composed of a raw material delivery system, a calcination system, a finished product delivery system and a smoke exhaust and dust removal system; the calcination system consists of a multi-stage preheating cyclone separator 1-6 , calcining reactor 7, intermediate separator 8 and multistage cooling cyclone separator 9-17; Wherein:

[0029] The multi-stage preheating cyclone separators 1-6 are equally divided into multiple groups, and each group is composed of several preheating cyclone separators; the feeding device 24 of the raw material delivery system is connected with the feeding pipeline before the first-stage preheating cyclone separator, and the multi-stage The feeding pipelines of the preheating cyclone separators 1-6 are connected in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com