High-speed low-loss mixed medium differential transmission signal line structure

A mixed-media, differential transmission technology, applied in the field of communication materials, can solve problems such as insufficient consistency control, unstable conductor center distance, and affecting signal characteristic transmission, etc., to achieve optimal tuning and differential and common mode impedance, large shielding area, The effect of excellent transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

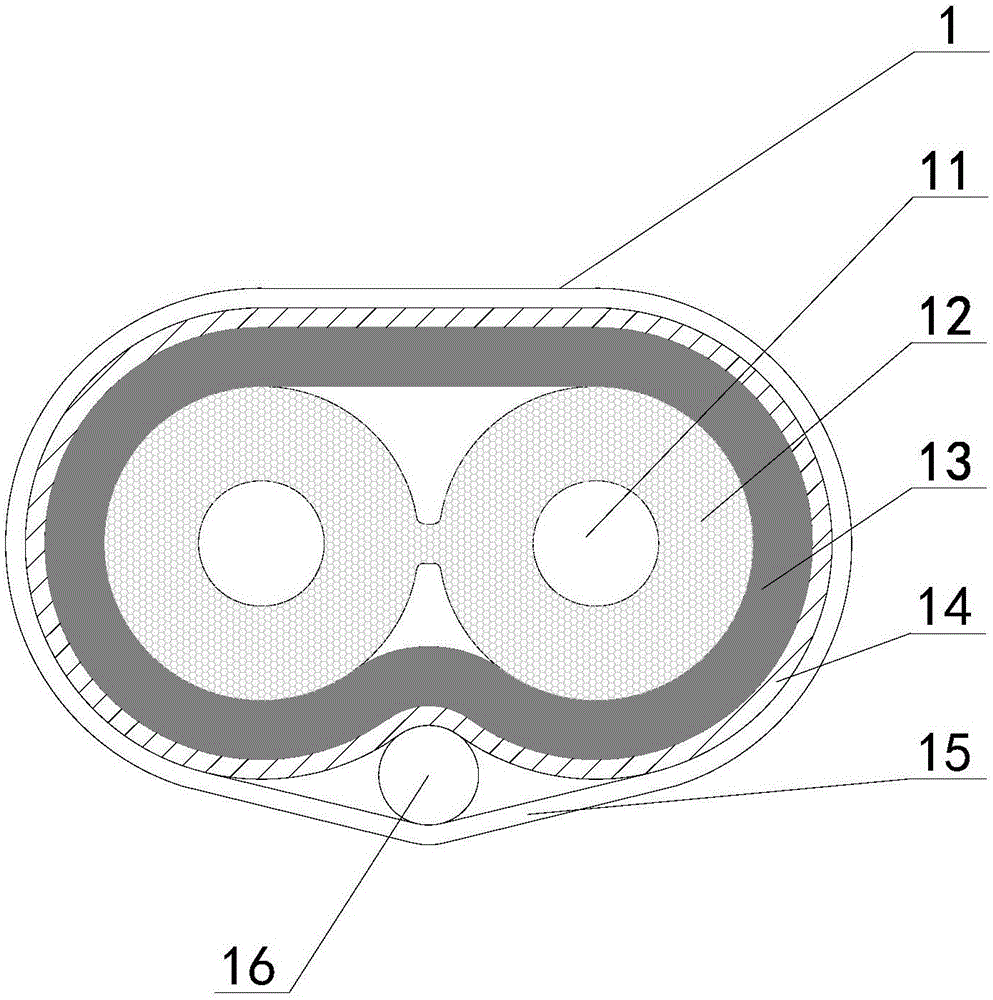

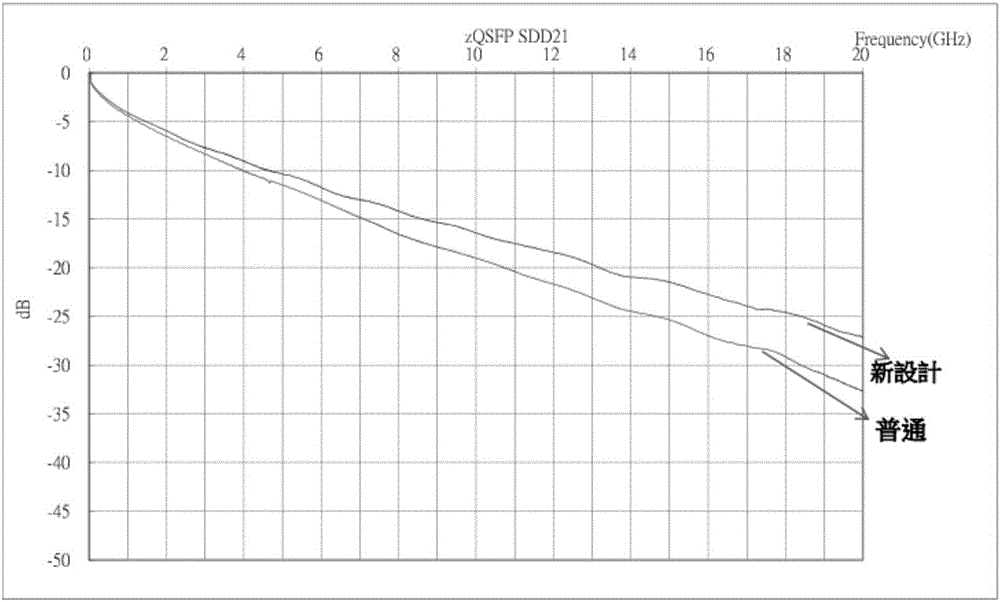

[0021] Such as Figure 1-2 As shown, the high-speed low-loss mixed-medium differential transmission signal line structure includes a main body 1, a conductor 11, a first insulating layer 12, a second insulating layer 13, a shielding layer 14, a mylar layer 15, and a ground wire 16. The first insulating layer The layer 12 wraps the conductor 11 to form a core wire. The two core wires are placed side by side or twisted to each other and are wrapped sequentially through the second insulating layer 13 and the shielding layer 14 to form a wrapping wire, and the first insulating layer of the two core wires 12 is connected as a whole through PE extrusion, and the mylar layer 15 wraps the wrapping wire and the ground wire 16 to form the signal wire structure main body 1; the material of the first insulating layer 12 is Skin-Foam-Skin or HDPE; The second insulating layer 13 is an EPTFE layer, and the EPTFE layer is formed by winding an EPTFE tape, and the winding overlap rate is 50%; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com