Far-infrared multistage heating furnace for hot-pressed steel plate

A hot-pressed steel plate and far-infrared ray technology, which is applied in electric furnace heating, heat treatment furnace, ohmic resistance heating, etc., can solve the problems of reduced pressing formability and inability to manufacture pressed formed products, so as to improve heat uniformity and reduce maintenance costs , the effect of improving the operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is described with reference to the drawings.

[0054] 1. The structure of the furnace frame 12

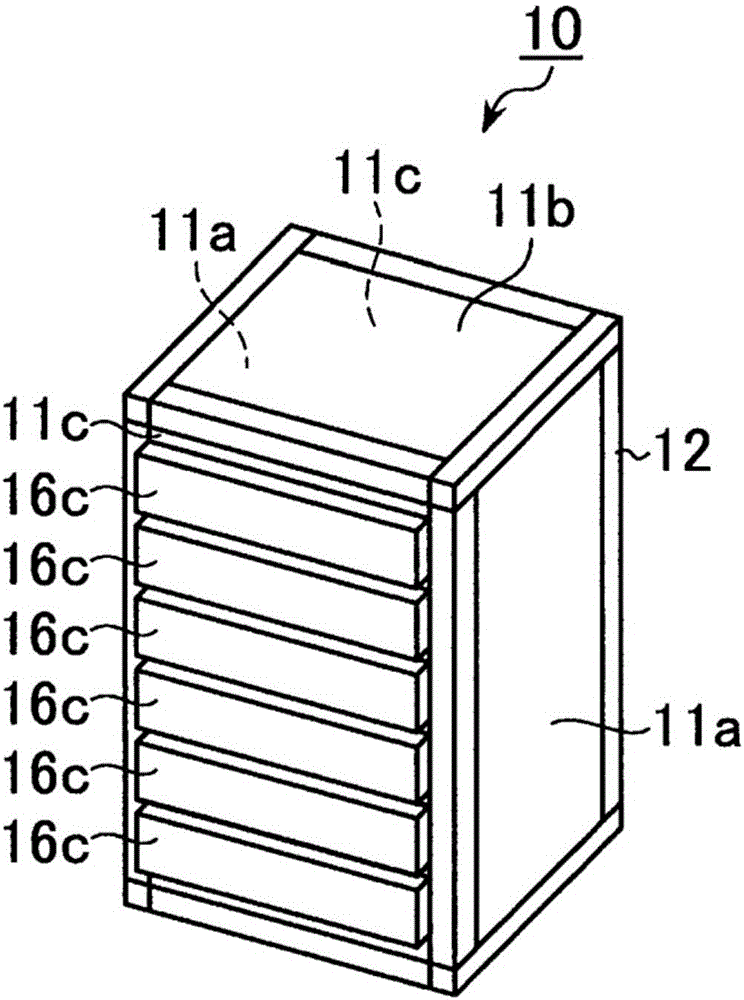

[0055] figure 2 It is an overall view showing the far-infrared multi-layer heating furnace 10 of the present invention, and is an explanatory view showing outer shell panels 11 a , 11 b , and 11 c and a furnace body frame 12 .

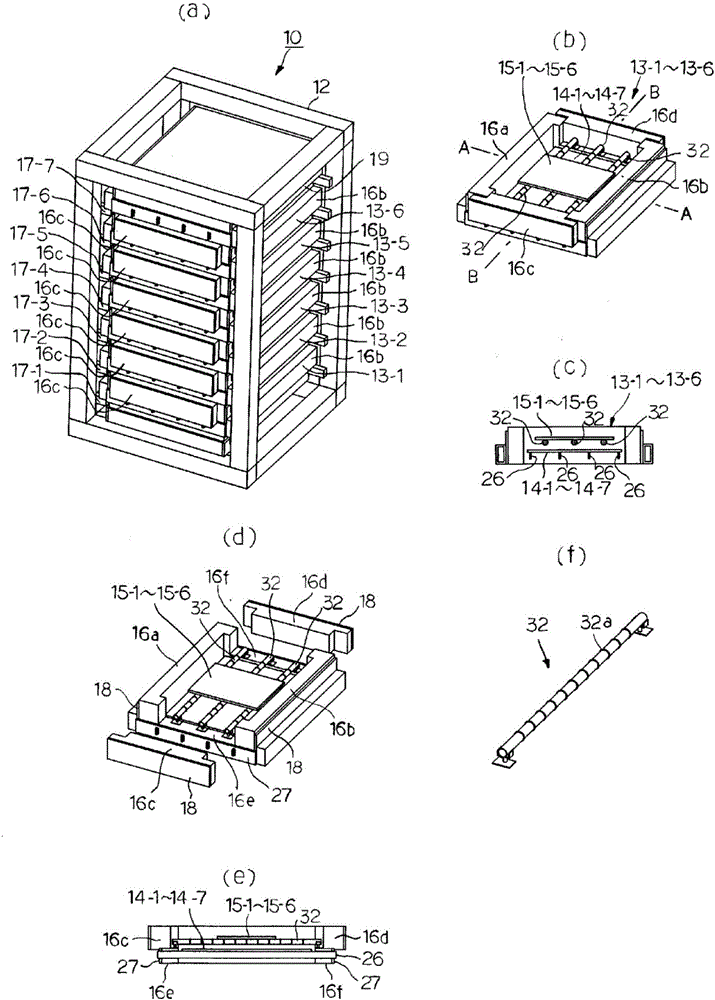

[0056] image 3 It is an explanatory diagram of the far-infrared multilayer heating furnace 10 of the present invention, image 3 (a) is an explanatory diagram showing the appearance of the far-infrared multilayer heating furnace 10, image 3 (b) is an explanatory diagram showing the heating units 13-1 to 13-6, image 3 (c) is image 3 A-A sectional view in (b), image 3 (d) is an explanatory diagram showing the heating units 13-1 to 13-6 in a state where the cover blocks 16c, 16d are removed, image 3 (e) is image 3 B-B sectional view in (b), image 3 (f) is a perspective view showing the steel plate support member 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com