Motor control device, motor control method, and motor control system

A technology for a control device and a motor, which is applied in the direction of controlling multiple AC motors, converting irreversible DC power input into AC power output, etc., can solve the problems of large conduction noise, radiated noise, large influence, and inability to become large noise, etc. Achieve the effect of avoiding conducted noise and reducing radiated noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

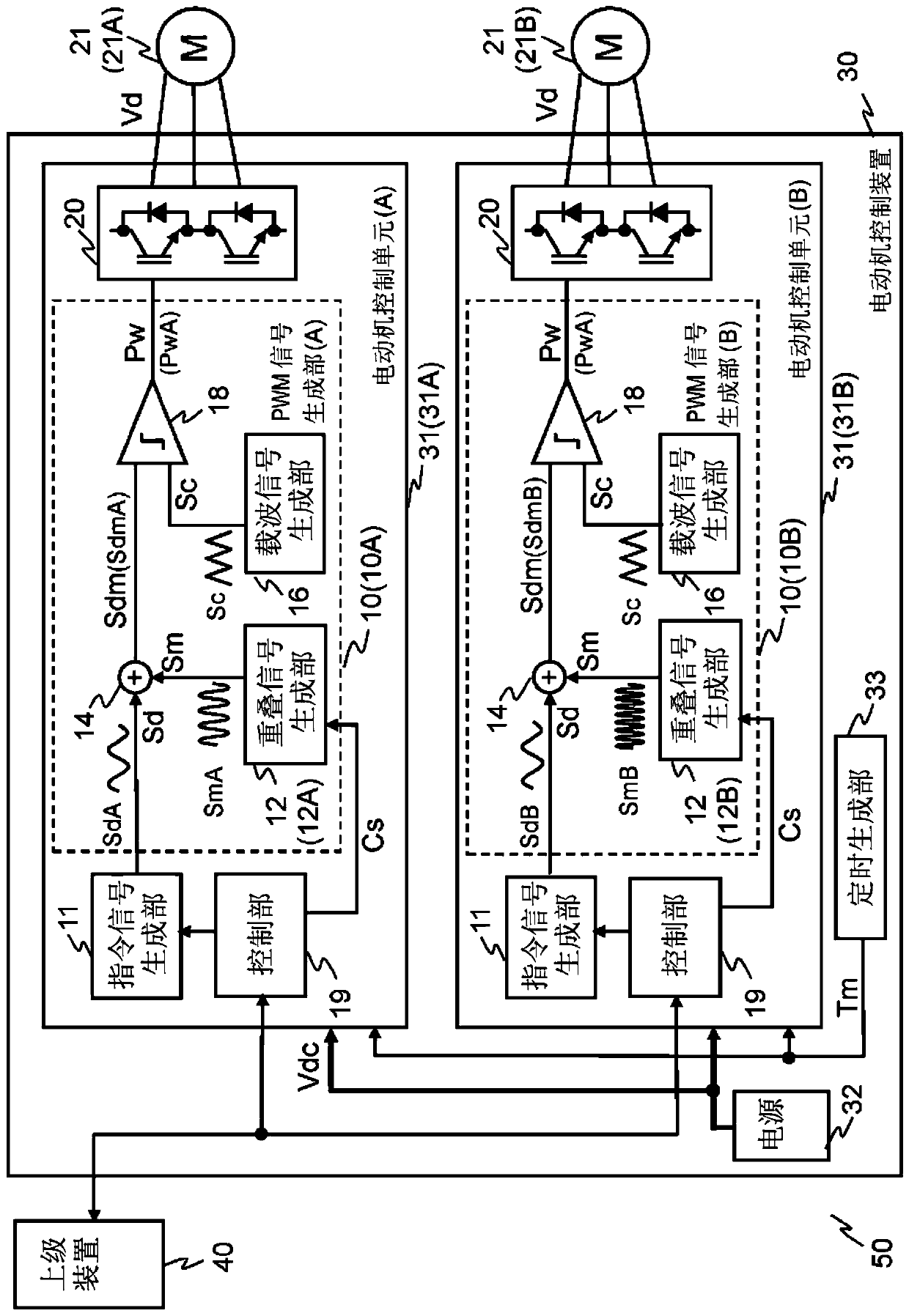

[0030] figure 1 It is a configuration diagram of a motor control system including a motor control device in an embodiment of the present invention. exist figure 1 In the figure, as an example of such a system, the configuration of a motor control system 50 for multi-axis motor control including a motor control device 30 that controls a plurality of motors 21 is shown. Also, as multiple axes, in figure 1 An example including two motors 21 as two shafts is shown in . Furthermore, in order to control the motor control device 30 by commands or the like, the present motor control system 50 also includes a host device 40 using a personal computer or the like, for example. The host device 40 and the motor control device 30 are communicatively connected via a control bus or the like. Commands from the host device 40 are transmitted to the motor control device 30 and information from the motor control device 30 is transmitted to the host device 40 .

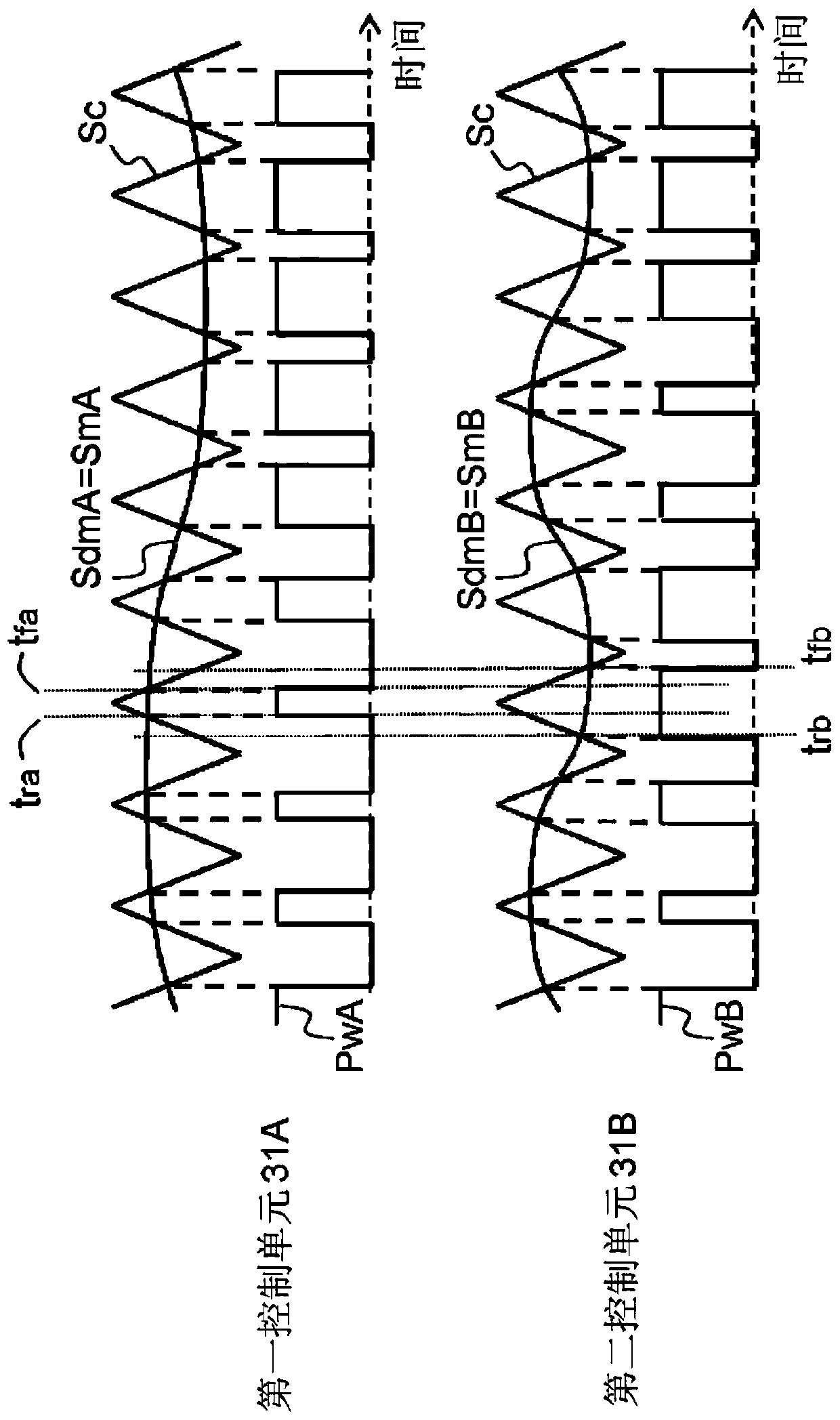

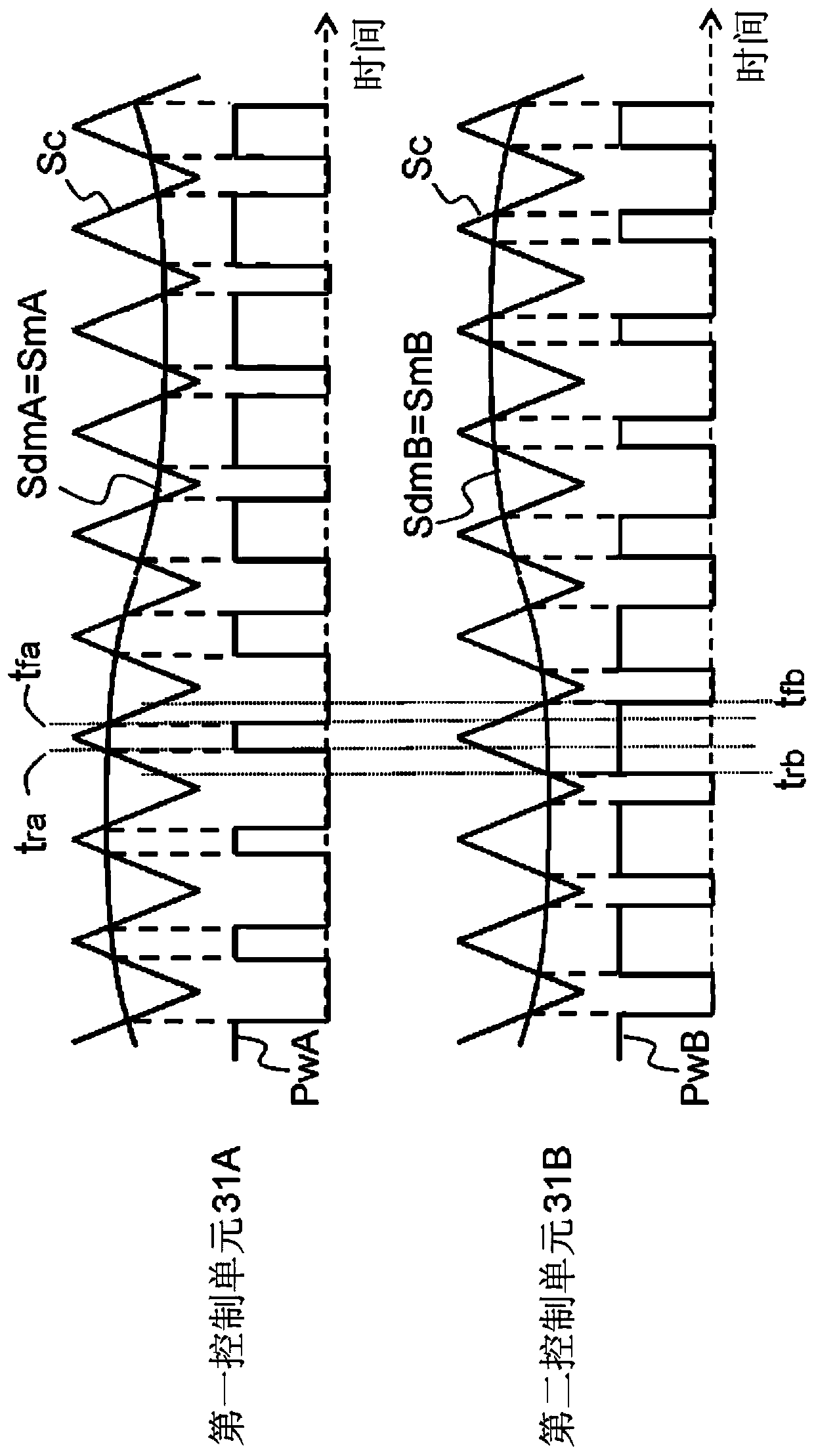

[0031] Next, in order to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com