Method for preparing psidium guajave slices by use of closed-loop dehumidification-heat pump technology

The technology of guava slices and heat pump technology is applied in the directions of food ingredients as taste improvers, food ingredients as taste improvers, food science and other directions, which can solve problems such as short storage time, and achieve good taste, full texture and original fruit flavor. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

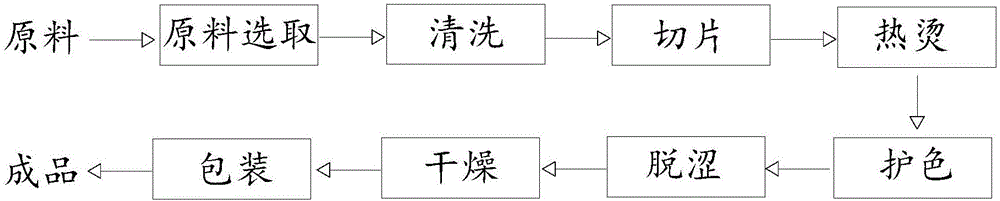

[0030] Example 1, see figure 1 :

[0031] The invention provides a kind of adopting closed-loop dehumidification-heat pump technology to make guava slices and a preparation method thereof, adopting closed-loop dehumidification-heat pump drying technology, comprising the following steps:

[0032] 1) Raw material selection: select guavas that are fresh and plump, nearly mature, free from rot and mechanical damage, and basically consistent in shape;

[0033] 2) Cleaning: wash away the surface dirt of the guava raw material, and temporarily store it in the color protection solution;

[0034] 3) Slicing: Cut off the two ends of the cleaned guava pulp, then cut it into round guava slices, with a thickness of 0.2cm;

[0035] 4) blanching: blanching the guava slices at 85°C;

[0036] 5) Color protection: the mass concentration of 0.2% CaCl 2 , 0.5% of 6° mature vinegar and 0.3% of Na 2 HS0 3 Mix at a volume ratio of 1:1:1, pour the blanched guava slices into it, soak for 0.8h, r...

Embodiment 2

[0041] The invention provides a kind of adopting closed-loop dehumidification-heat pump technology to make guava slices and a preparation method thereof, adopting closed-loop dehumidification-heat pump drying technology, comprising the following steps:

[0042] 1) Raw material selection: select guavas that are fresh and plump, nearly mature, free from rot and mechanical damage, and basically consistent in shape;

[0043] 2) Cleaning: wash away the surface dirt of the guava raw material, and temporarily store it in the color protection solution;

[0044] 3) Slicing: Cut off the two ends of the cleaned guava pulp, then cut it into round guava slices, with a thickness of 0.2cm;

[0045] 4) blanching: blanching the guava slices at 82°C;

[0046] 5) Color protection: the mass concentration of 0.2% CaCl 2 , 0.5% of 6° mature vinegar and 0.3% of Na 2 HS0 3 Mix at a volume ratio of 1:1:1, pour the blanched guava slices into it, soak for 0.8h, remove the guava slices, rinse with cl...

Embodiment 3

[0051] The invention provides a kind of adopting closed-loop dehumidification-heat pump technology to make guava slices and a preparation method thereof, adopting closed-loop dehumidification-heat pump drying technology, comprising the following steps:

[0052] 1) Raw material selection: select guavas that are fresh and plump, nearly mature, free from rot and mechanical damage, and basically consistent in shape;

[0053] 2) Cleaning: wash away the surface dirt of the guava raw material, and temporarily store it in the color protection solution;

[0054] 3) Slicing: Cut off the two ends of the cleaned guava pulp, then cut it into round guava slices, with a thickness of 0.2cm;

[0055] 4) blanching: blanching the guava slices at 88°C;

[0056] 5) Color protection: the mass concentration of 0.2% CaCl 2 , 0.5% of 6° mature vinegar and 0.3% of Na 2 HS0 3 Mix at a volume ratio of 1:1:1, pour the blanched guava slices into it, soak for 0.8h, remove the guava slices, rinse with cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com