Method for making banana slices by closed-loop dehumidification-heat pump technology

A heat pump technology and banana chip technology, which are applied in the field of food manufacturing, can solve the problems of loss of nutrients, unevenness and roundness, wrinkled appearance, etc., and achieve the effect of long shelf life, smooth surface and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

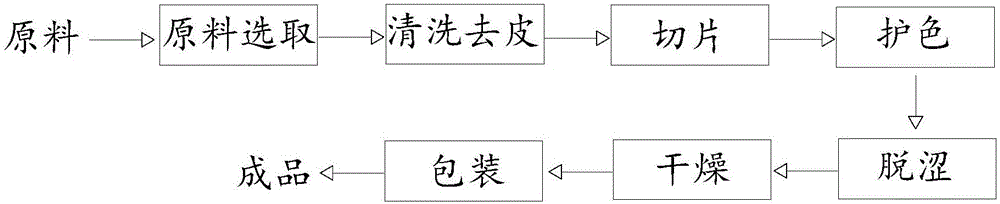

[0028] Example 1, see figure 1 :

[0029] The present invention provides a kind of method adopting closed-loop dehumidification-heat pump technology to make banana chips, adopting closed-loop dehumidification-heat pump drying technology, comprising the following steps:

[0030] 1) Raw material selection: select banana fruits with basically the same size and maturity and without any defects in appearance;

[0031] 2) Cleaning and peeling: wash off the surface dirt of the raw bananas, peel off the banana peels manually, and put them in the color protection solution for temporary storage;

[0032] 3) Slicing: Cut off the two ends of the cleaned banana pulp, and then cut it into circular banana slices with a thickness of 0.3cm;

[0033] 4) Color protection: Clean and peel the fresh pineapple fruit without pests and diseases, put it in a juicer, add 4 times the quality of drinking water, squeeze the juice with a squeezer, and then use a centrifuge to centrifuge at a speed of 1000...

Embodiment 2

[0038] The present invention provides a kind of method adopting closed-loop dehumidification-heat pump technology to make banana chips, adopting closed-loop dehumidification-heat pump drying technology, comprising the following steps:

[0039] 1) Raw material selection: select banana fruits with basically the same size and maturity and without any defects in appearance;

[0040]2) Cleaning and peeling: wash off the surface dirt of the raw bananas, peel off the banana peels manually, and put them in the color protection solution for temporary storage;

[0041] 3) Slicing: cut off the two ends of the cleaned banana pulp, and then cut it into round banana slices with a thickness of 0.4cm;

[0042] 4) Color protection: Clean and peel the fresh pineapple fruit without pests and diseases, put it in a juicer, add 4 times the quality of drinking water, squeeze the juice with a squeezer, and then use a centrifuge to centrifuge at a speed of 10000r / min 29 minutes, take out the supernat...

Embodiment 3

[0047] The present invention provides a kind of method adopting closed-loop dehumidification-heat pump technology to make banana chips, adopting closed-loop dehumidification-heat pump drying technology, comprising the following steps:

[0048] 1) Raw material selection: select banana fruits with basically the same size and maturity and without any defects in appearance;

[0049] 2) Cleaning and peeling: wash off the surface dirt of the raw bananas, peel off the banana peels manually, and put them in the color protection solution for temporary storage;

[0050] 3) Slicing: cut off both ends of the cleaned banana pulp, and then cut it into round banana slices with a thickness of 0.2cm;

[0051] 4) Color protection: Clean and peel the fresh pineapple fruit without pests and diseases, put it in a juicer, add 4 times the quality of drinking water, squeeze the juice with a squeezer, and then use a centrifuge to centrifuge at a speed of 10000r / min After 25 minutes, take out the supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com