Black hair dyeing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

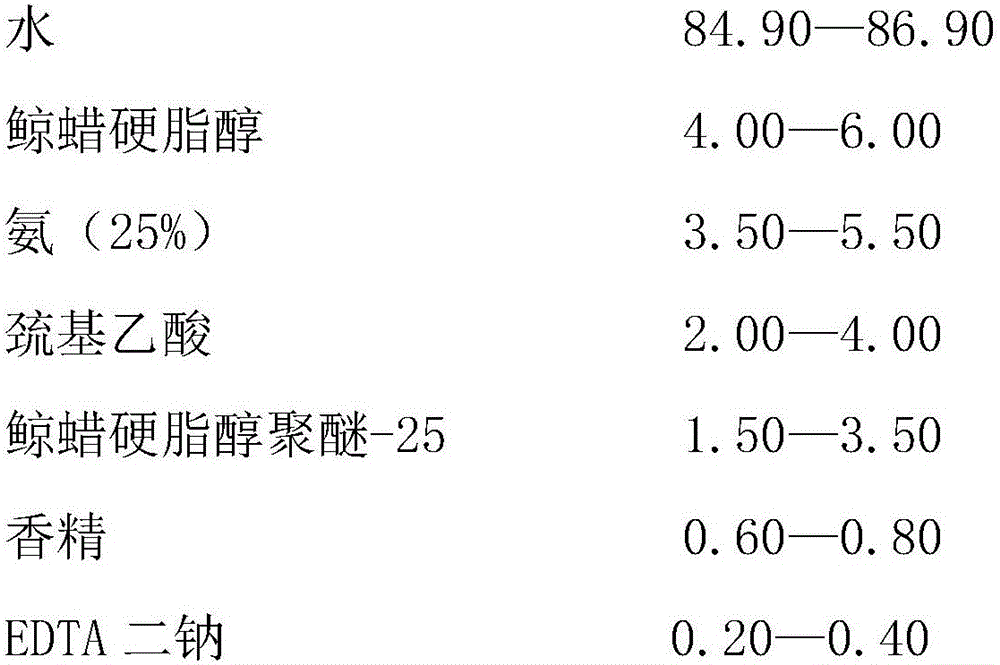

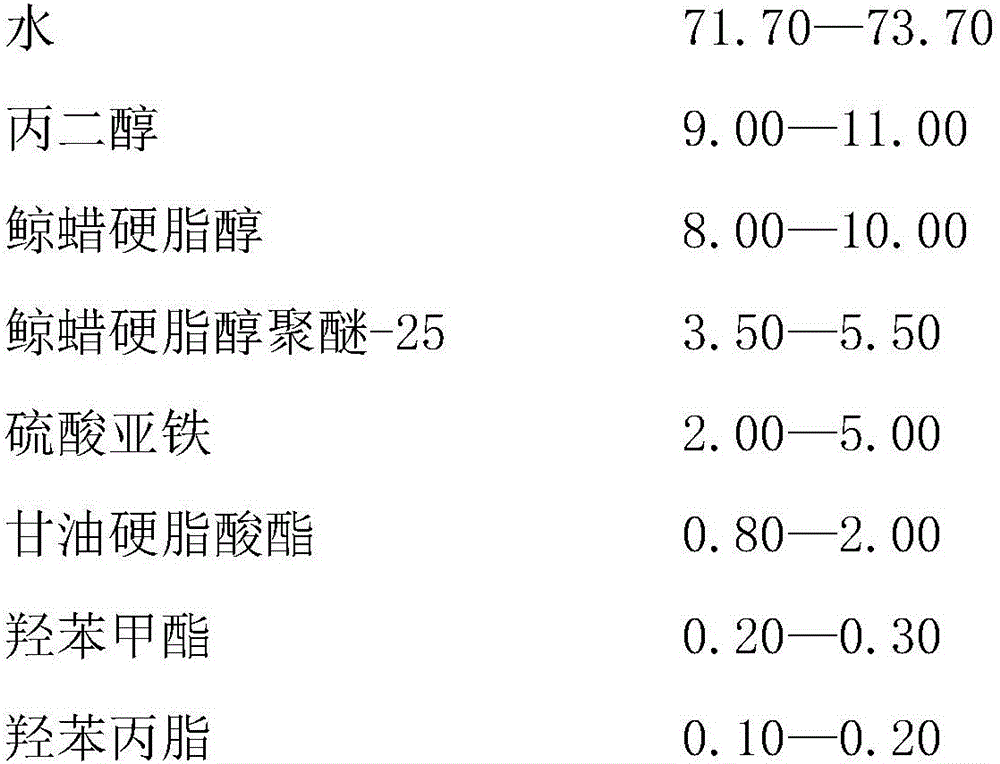

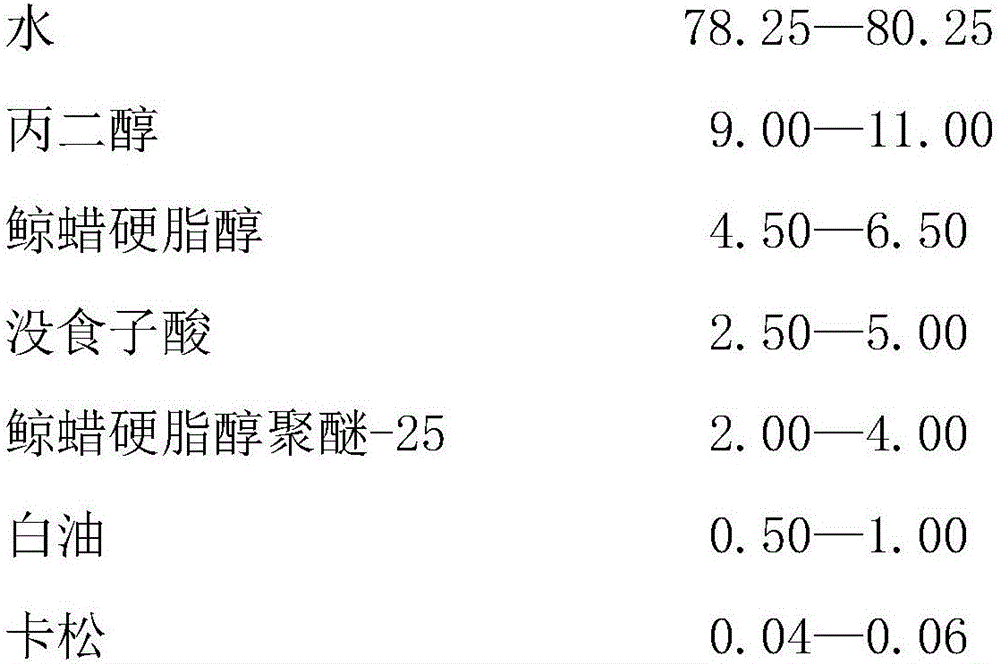

[0014] Ⅰ agent:

[0015] In step (1), add 25 kg of water and 2 kg of thioglycolic acid into a plastic container, then slowly add 3.5 kg of 25% ammonia by weight, and stir evenly to obtain 30.5 kg as the C1 phase raw material;

[0016] In step (2), add 4kg of cetearyl alcohol and 251.5kg of ceteareth-251.5kg into the oil phase tank, heat to 80-90°C, stir evenly to obtain 7.5kg, and use it as the raw material of A1 phase;

[0017] In step (3), 59.9kg of water and 0.2kg of disodium EDTA are added to the water phase tank and heated to 90-95°C, and stirred evenly to obtain 60.3kg, which is used as the raw material of B1 phase;

[0018] In step (4), 7.5kg of A1-phase raw materials and 60.3kg of B1-phase raw materials are pumped into an emulsification tank, stirred evenly, and emulsified at a temperature of 80-85°C for a certain period of time to obtain 67.8kg of raw materials;

[0019] Step (5), when the 67.8kg of raw material emulsified in the step (4) is cooled to 40°C, slowly ad...

Embodiment 2

[0033] Ⅰ agent:

[0034] Step (1), add 26kg of water and 4kg of thioglycolic acid into a plastic container, then slowly add 5.5kg of ammonia water with a weight percentage of 25%, stir evenly to obtain 35.5kg, as the C1 phase raw material;

[0035] In step (2), add 6kg of cetearyl alcohol and 253.5kg of ceteareth-253.5kg into the oil phase tank, heat to 80-90°C, stir evenly to obtain 9.5kg, and use it as the raw material of A1 phase;

[0036] In step (3), add 60.9kg of water and 0.4kg of disodium EDTA into the water phase tank and heat to 90-95°C, and stir evenly to obtain 61.3kg, which is used as the raw material of B1 phase;

[0037] In step (4), 9.5kg of A1-phase raw materials and 61.3kg of B1-phase raw materials are pumped into an emulsification tank, stirred evenly, and emulsified at a temperature of 80-85°C for a certain period of time to obtain 70.8kg of raw materials;

[0038] Step (5), when the 70.8kg raw material emulsified in the step (4) is cooled to 40°C, slowly ...

Embodiment 3

[0052] Ⅰ agent:

[0053] Step (1), adding 25.5kg of water and 3kg of thioglycolic acid into a plastic container, then slowly adding 4kg of ammonia water with a weight percentage of 25%, stirring evenly to obtain 32.5kg, as the C1 phase raw material;

[0054] In step (2), 5kg of cetearyl alcohol and 252kg of ceteareth-252kg are added to the oil phase tank and heated to 80-90°C, and stirred evenly to obtain 7.5kg, which is used as the raw material of A1 phase;

[0055] Step (3), add 60.4kg of water and 0.3kg of disodium EDTA into the water phase tank and heat to 90-95°C, stir evenly to obtain 60.7kg, which is used as the raw material of B1 phase;

[0056] In step (4), 7.5kg of A1-phase raw materials and 60.7kg of B1-phase raw materials are pumped into an emulsification tank, stirred evenly, and emulsified at a temperature of 80-85°C for a certain period of time to obtain 68.2kg of raw materials;

[0057]Step (5), when the 68.2kg of raw material emulsified in the step (4) is coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com