Biomass energy fuel pelleter

A biomass energy and pellet mill technology, applied in grain processing and other directions, can solve problems such as low production efficiency, and achieve the effect of easy maintenance and precise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

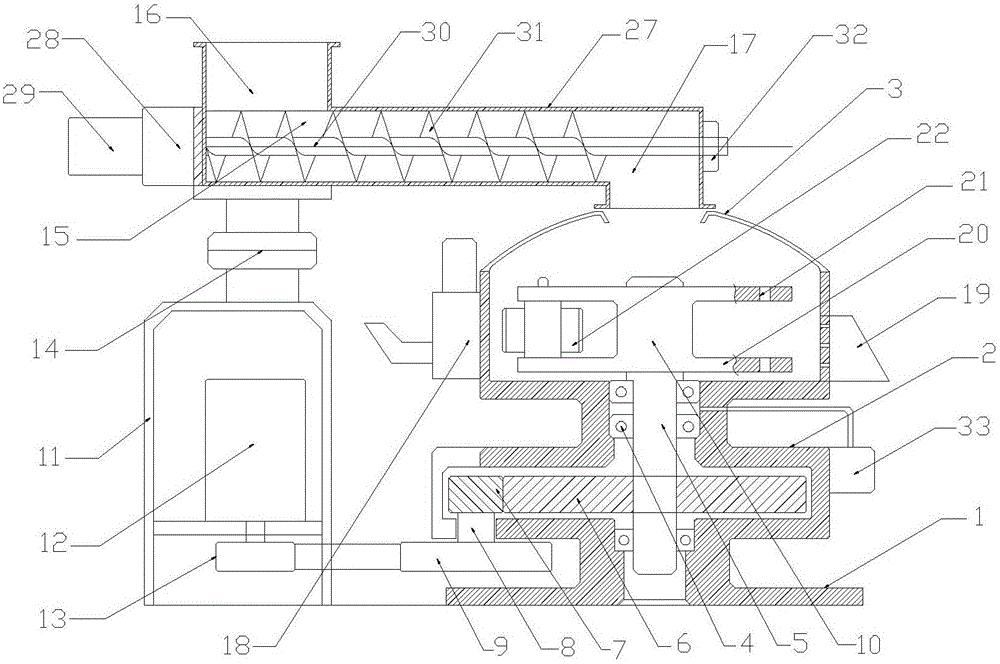

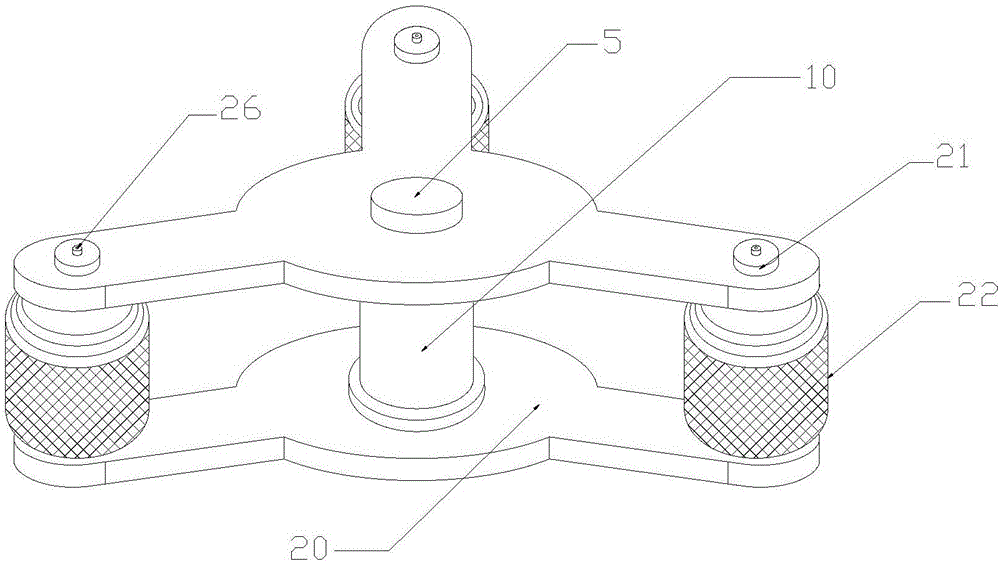

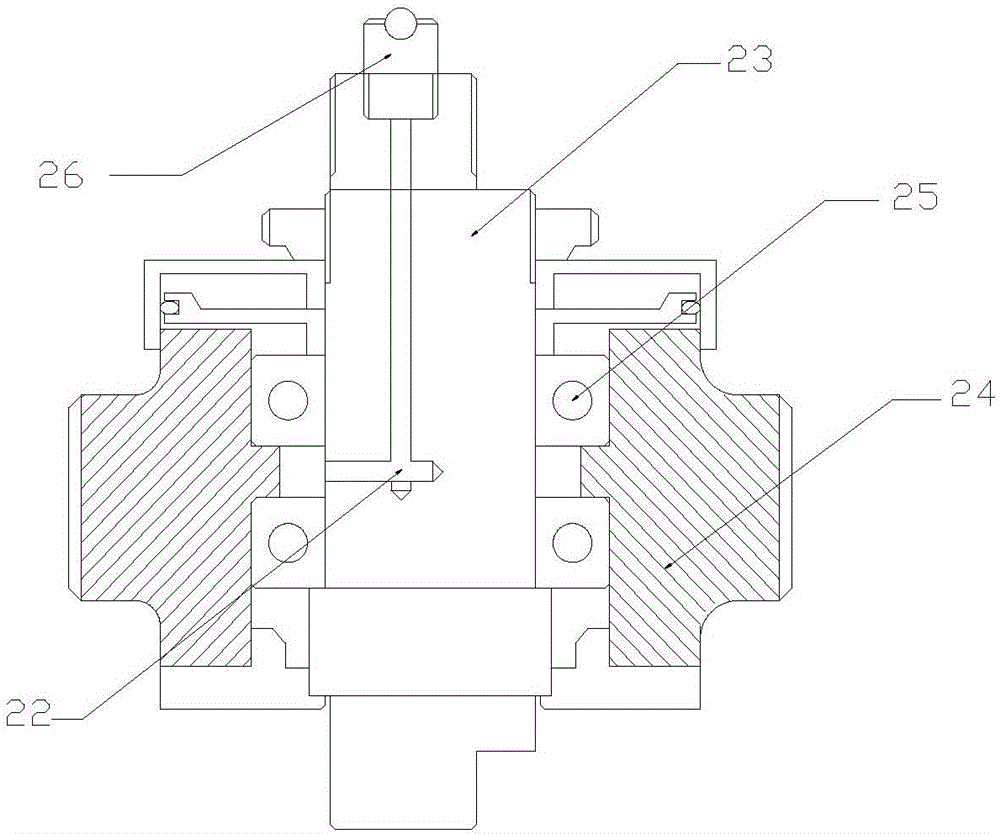

[0022] Such as Figure 1-3 As shown, the present invention provides a biomass fuel pelletizer, comprising a crushing extruder 1, a pressing roller assembly 10 and a feeder assembly 15, and the crushing extruder 1 includes an hourglass-shaped main engine housing 2 , the top of the host housing 2 is provided with a dome feed inlet 3, the middle of the inner cavity of the host housing 2 is embedded with a power spindle 5 through the spindle bearing 4 connected by fitting, and the bottom end of the power spindle 5 is connected with a The main shaft gear 6, one side of the main shaft gear 6 is meshed with a transmission gear 7, the center of the transmission gear 7 is coaxially connected with a large pulley 9 through the transmission shaft 8, and the top of the power main shaft 5 is connected in series with a pressure roller assembly 10. One side of the host housing 2 is fixed with a mounting frame 11, and the middle part of the mounting frame 11 is fixed with a crushing motor 12 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com