A kind of mushroom bag waste processing device

A waste treatment and mushroom technology, applied in the field of mushroom bag waste treatment devices, can solve the problems of waste of resources, white pollution of mushroom bags, waste of resources, etc., and achieve the effect of easy replacement, long-term use, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

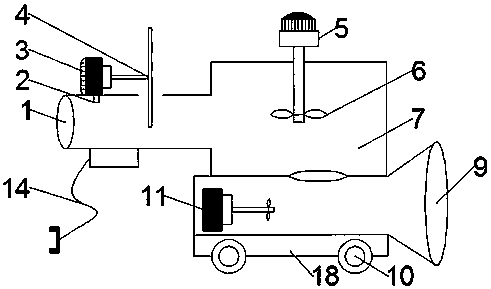

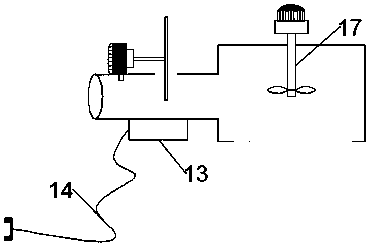

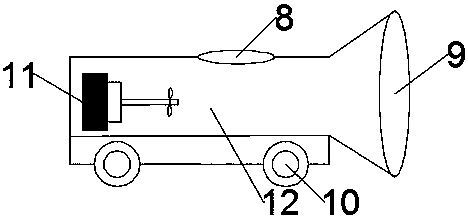

[0022] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a kind of technical scheme: a kind of mushroom package waste processing device, comprises crushing bin 7 and discharging bin 12, is provided with blower 11 at the left end of discharging bin 12 inside, and the power of blower 11 is 2.2 kilowatts, simultaneously The operating voltage is 220 volts, which ensures that the power supply is convenient and also provides a strong blowing force to ensure that the waste can be sprayed out, and the right end of the discharge bin 12 is provided with a discharge port 9, and the discharge port 9 is welded on the discharge port. On the silo 12, a feed port 8 is provided on the top of the discharge silo 12;

[0023] The upper surface of the discharge bin 12 is provided with a crushing bin 7, and the crushing bin 7 is made of engineering plastics, which greatly reduces the quality of the main body of the device while ensuring the service life. Weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com