Pressure cast metal hand mold and preparation method thereof

A technology of casting metal and hand molds, which is applied in the preparation of pressure casting metal hand molds and in the field of pressure casting metal hand molds. It can solve the problem of not being able to accurately ensure the levelness, verticality and actual requirements of impregnation of hand molds, and affect the stability of glove dipping. and reliability, affecting heat exchange and dipping production process, etc., to achieve smooth and bright appearance, reduce grinding workload, and easy to control wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

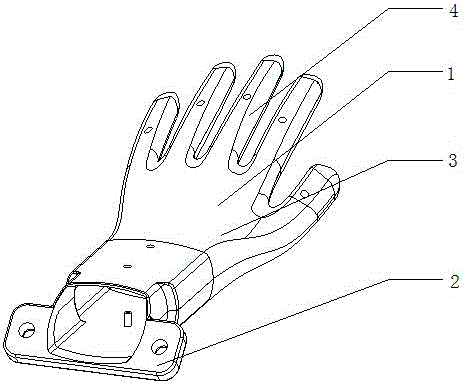

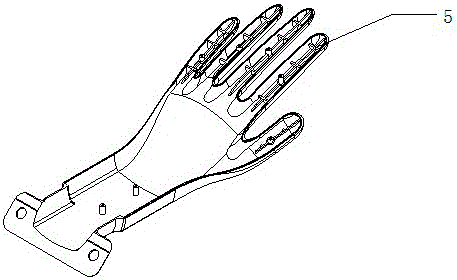

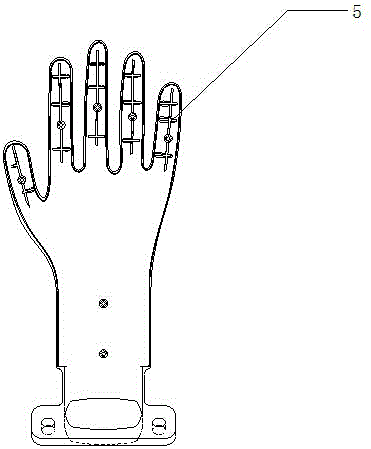

[0034] Such as figure 1 , figure 2 and image 3 As shown, a die casting metal hand mold includes a hand mold body 1 and a fixed base 2. The hand mold body 1 includes a palm part 3 and a finger part 4. Both the palm part 3 and the finger part 4 are designed to simulate the structure of a human hand. The hand mold body 1 is divided into two halves along its longitudinal direction, one half is the palm part, the other half is the back part of the hand, and the palm part and the back part of the hand are buckled and fixed to form a complete hand model. Reinforcing ribs 5 arranged longitudinally and transversely are arranged on the concave surface of the finger portion 4 .

[0035] The fixed connection between the palm surface part and the back p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com