Vertical circulation transmission structure of serving machine

A technology of transmission structure and vertical circulation, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of inability to move, large amount of engineering, increased labor intensity, etc. The effect of the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

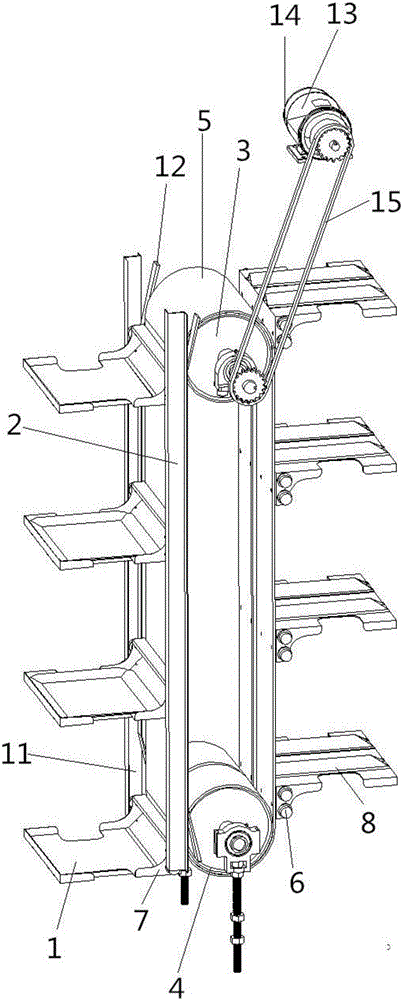

[0035] Such as figure 1 As shown, this embodiment discloses a transmission structure of a vertical circulation serving machine, which is composed of a drive device, a tray 1, a circulation transmission device, a gravity rotation device for a tray, and a tray guide rail 2; wherein, the circulation transmission device includes and drives The main transmission wheel, the auxiliary transmission wheel and the conveyor belt connected to the device, the main transmission wheel and the auxiliary transmission wheel are respectively installed on both sides of the conveyor belt, and form a circular transmission structure with the conveyor belt. Axis 9 and angular rotation axis 10.

[0036] Wherein, in this embodiment, the angle of the angular rotation axis 10 is limited, so that the angular rotation axis 10 does not rotate any more after being turned over to the other side, and drives the tray 1 after turning over, only the orientation of the disk surface is different, and the angle is t...

Embodiment 2

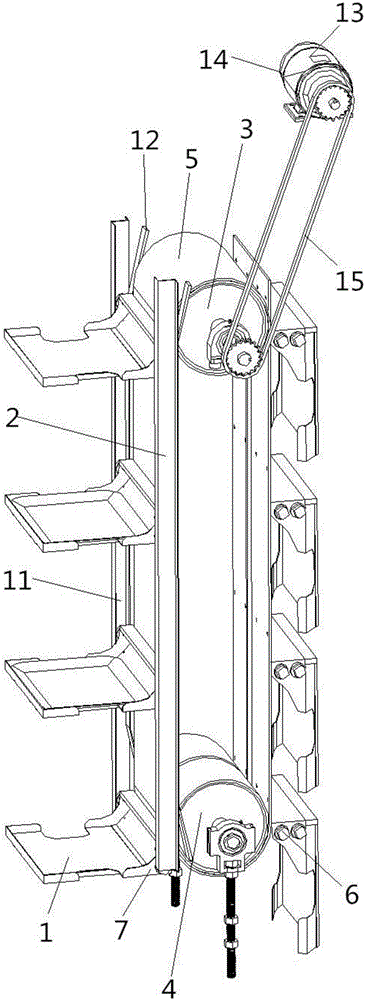

[0039] Such as figure 2 As shown, on the basis of Embodiment 1, the angle of the angular rotation shaft 10 is not limited, and the angular rotation shaft 10 can be stacked clockwise after turning over according to the action of gravity, so as to facilitate the reduction of the occupied space of the serving machine. The specific process is as follows: When the conveyor belt drives the tray to turn over the top of the serving machine, under the action of the gravity of the weight plate 8, the angular rotation axis 10 rotates 90 degrees clockwise, and drives the tray 1 to be stacked on the conveyor belt for storage. When the bottom of the machine is overturned again, under the action of the gravity of the weight plate 8, the angle rotating shaft 10 rotates 90 degrees counterclockwise, which drives the tray 1 to open, which is convenient for placing dishes.

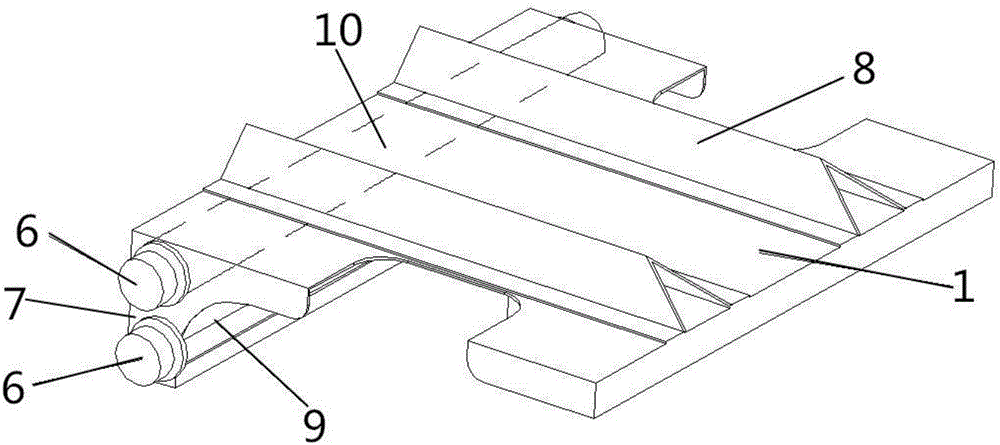

[0040] Such as image 3 As shown, the cam wheels are set on both sides of the angular rotation axis 10 and the fixed axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com