Miniaturized impact hammer with low driving voltages

A technology of low driving voltage and impact hammer, which is applied to the components of TV systems, microelectronic microstructure devices, TVs, etc., can solve the problems of limited MEMS micro impact hammers, cannot be widely used, and high driving voltage, so as to make up for the inability to Effects of wide application, reduced driving force, and reduced driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

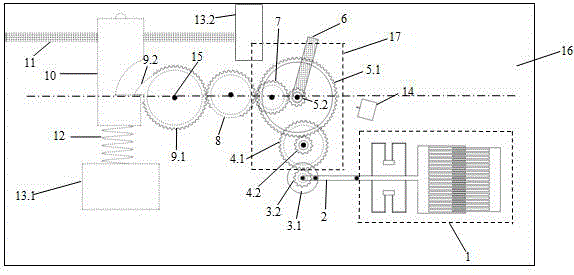

[0017] exist figure 1 The middle is a three-layer structure, the dotted gears at the index circle and the dotted structure (3.2, 4.2, 5.2, 7, 8, 9.1, 9.2, 10, 11, 12, 13) are at the bottom layer, and the solid line structure (1, 2 , 3.1, 4.1, 5.1) are in the middle layer, and the lever arm 6 and the mechanical lock 14 are in the top layer. The main gear 9.1 is integrated with the main gear driven block 9.2, the transmission gear 5.1 and the pinion gear 5.2 are 5:1 double-layer gears, and are integrated with the lever arm 6, the transmission gear 4.1 and the pinion gear 4.2 are 3:1 double-layer gears, and the pinion gears 3.2 is integrated with disc 3.1. pin 15 in figure 1 are represented as black dots.

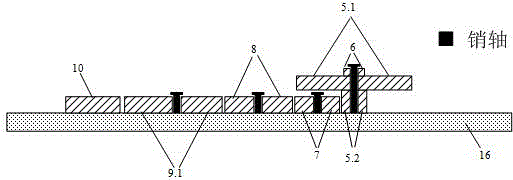

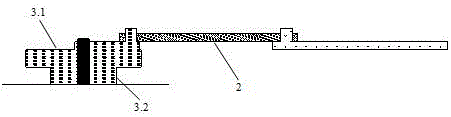

[0018] exist figure 2 , the component number indicates the same figure 1 ,for figure 1 Schematic diagram of the cross-section of the dotted lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com