Grout injection type waterproof high-viscoelasticity modified asphalt pavement mixture and preparation method thereof

A technology of asphalt mixture and modified asphalt, which is applied in the field of pavement mixture, can solve the problems of large voids, poor performance, and difficult maintenance of asphalt mixture, and achieve smooth and rough pavement surface, excellent high-temperature stability, and anti-fatigue powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A grouting type impermeable high viscoelastic modified asphalt pavement mixture

[0055] Grouting impermeable high viscoelastic modified asphalt pavement mixture,

[0056] Including the parent asphalt mixture, the grout filled into the parent asphalt mixture,

[0057] The parent asphalt mixture is compacted to form a skeleton void type high viscoelastic modified asphalt mixture with a porosity of 18% to 22%. The composition of the skeleton void type high viscoelastic modified asphalt mixture is calculated as : 100 parts of aggregate, 4.2-5.2 parts of high viscoelastic modified asphalt, 3.7-4.7 parts of filler;

[0058] The composition of the grouting material is calculated by weight: 100 parts of grouting material, 34-36 parts of water, and the grouting material is nanometer grouting material with high elastic modulus.

[0059] The composition design of the present invention is carried out in two steps: the first step is to design the skeleton void type high viscoelas...

Embodiment 2

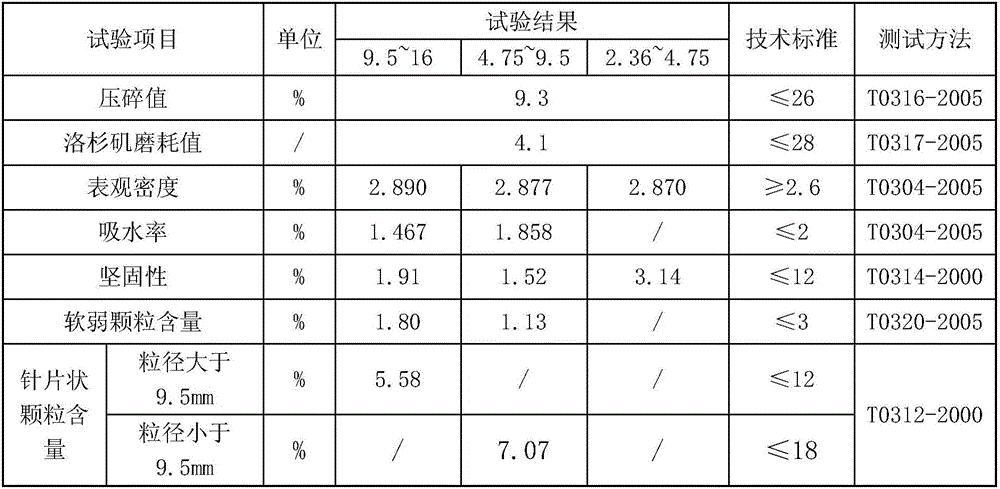

[0067] On the basis of Example 1: Preferably, the aggregate is made of hard basalt with high strength and good angularity, which facilitates the formation of a void ratio of 18% to 22%.

Embodiment 3

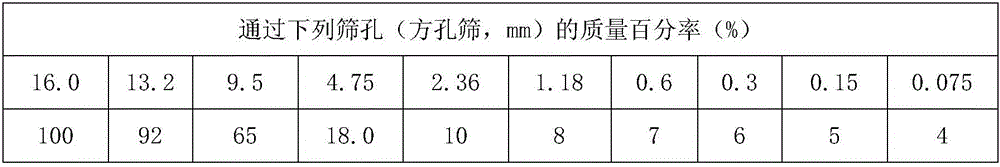

[0069] On the basis of Example 1, the synthetic gradation of the design aggregate is:

[0070] The aggregate passing rate of 16mm sieve is 100%,

[0071] The aggregate passing rate of 13.2mm sieve is 90%~94%,

[0072] The aggregate passing rate of 9.5mm sieve is 64%~68%,

[0073] The aggregate passing rate of the 4.75mm sieve is 13% to 22%.

[0074] The aggregate passing rate of 2.36mm sieve is 8%~13%,

[0075] The aggregate passing rate of 1.18mm sieve is 6% to 10%.

[0076] The aggregate passing rate of 0.6mm sieve is 5% to 8%.

[0077] The aggregate passing rate of 0.3mm sieve is 4% to 7%.

[0078] The aggregate passing rate of 0.15mm sieve is 3% to 15%.

[0079] The aggregate passing rate of 0.075mm sieve is 3% to 4%, and the sum of aggregate percentages of various particle sizes is 100%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Marshall stability | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com