Manufacturing process of helical wire type ceramic spring

A manufacturing process and helical technology, which is applied to the manufacturing process of ceramic springs, can solve the problems of large material consumption, high production cost, limited material range, etc., and achieve the effects of continuous preparation process, low requirements and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

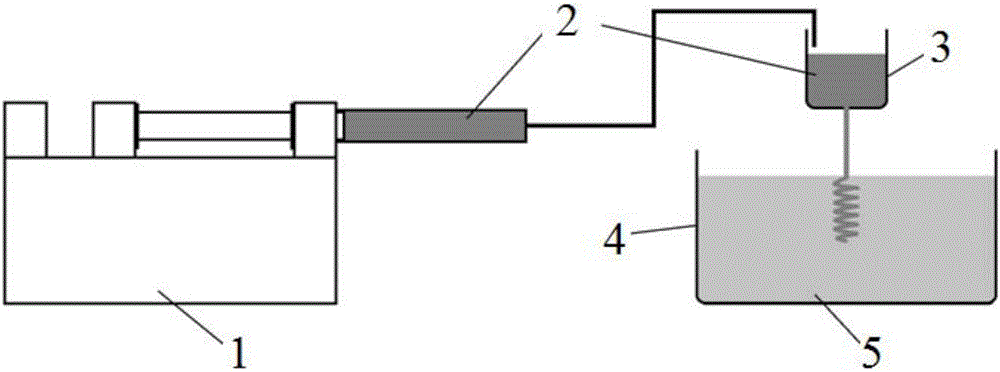

Method used

Image

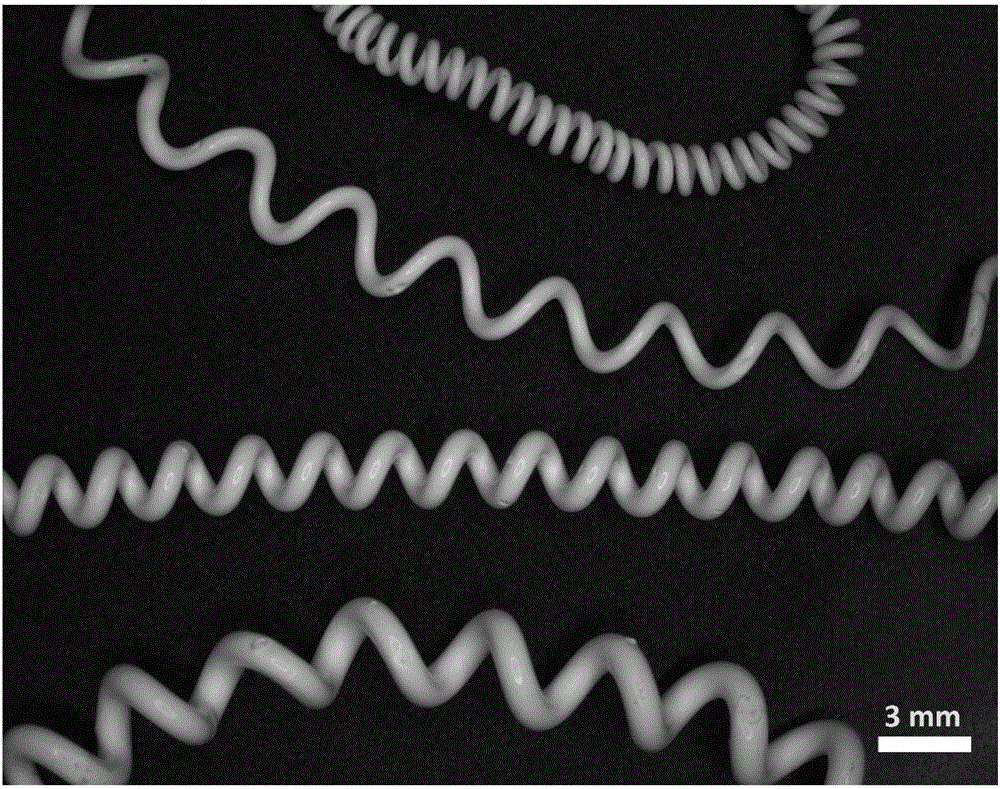

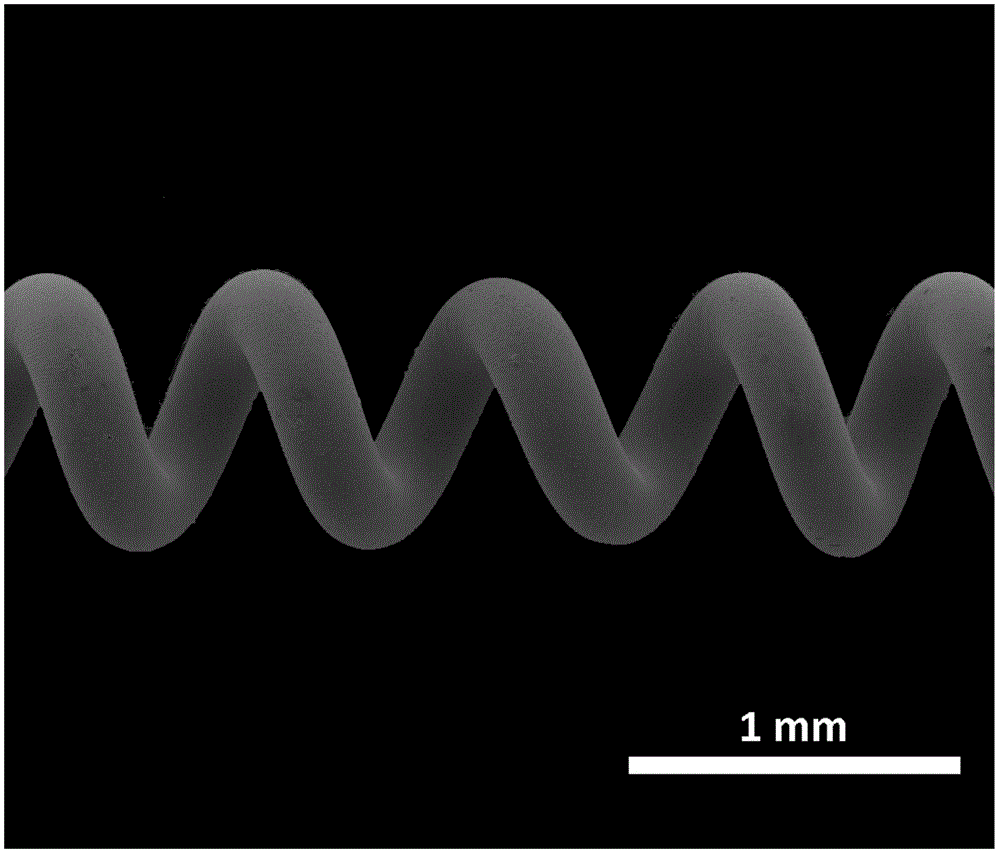

Examples

Embodiment 1

[0032] (1) Take 100g of YSZ powder with an average particle size of 0.2μm and 3wt.% yttrium oxide content, add 150g of analytically pure NMP solution, ultrasonically disperse for 15min, then add 50g of PES polymer, and place it in an oil bath at 50℃ Stir mechanically for 12 hours at a stirring speed of 300r / min, so that the slurry is fully mixed and uniform. After the slurry is cooled to room temperature, it is placed in a vacuum dryer for air extraction and defoaming, and then left for 12 hours to obtain a uniform composition Spinning solution

[0033] (2) Put the spinning solution into the syringe and load it into the syringe pump, and push it to the discharge tank at a flow rate of 7.5L / min. After the liquid level in the discharge tank rises to a stable level, use the receiving tank to receive the outflow slurry. Control the distance between the round hole at the bottom of the discharge tank and the surface of the coagulation bath to be 20cm. After the slurry enters the coagul...

Embodiment 2

[0036] (1) Take 40g of alumina powder with an average particle size of 0.05μm, add 80g of analytically pure DMSO solution, ultrasonically disperse for 15min, then add 30g of PES polymer, and mechanically stir for 12h in an oil bath at 60°C at a stirring speed of 200r / min, make the slurry fully mixed and uniform. After the slurry is cooled to room temperature, place it in a vacuum dryer to pump air until there are no bubbles on the liquid surface, and then stand for 6 hours to obtain a spinning solution with uniform composition;

[0037] (2) Put the spinning solution into the syringe and load it into the syringe pump, and push it to the discharge tank at a flow rate of 10L / min. After the liquid level in the discharge tank rises to a stable level, use the receiving tank to receive the outflow slurry and control The distance between the round hole at the bottom of the discharging tank and the surface of the coagulation bath is 15cm. After the slurry enters the coagulation bath, it s...

Embodiment 3

[0040] (1) Take 120g of YSZ powder with an average particle size of 0.5μm and a yttrium oxide content of 5wt.%, add 180g of analytically pure DMAC solution, ultrasonically disperse for 30min, then add 90g of PVDF polymer, and place it in an oil bath at 60℃ It is mechanically stirred for 24 hours, and the stirring speed is 400r / min, so that the slurry is fully mixed and uniform. After the slurry is cooled to room temperature, place it in a vacuum dryer for degassing, and then stand for 6 hours to obtain a spinning solution with uniform composition;

[0041] (2) Put the spinning solution into the syringe and load it into the syringe pump, and push it to the discharge tank at a flow rate of 20L / min. After the liquid level in the discharge tank rises to a stable level, use the receiving tank to receive the outflow slurry and control The distance between the round hole at the bottom of the discharging tank and the surface of the coagulation bath is 18cm. After the slurry enters the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com