A kind of method of synthesizing dimethyl carbonate

A technology of dimethyl carbonate and ethylene carbonate, which is applied in the field of preparation of dimethyl carbonate, can solve the problems of difficulty in catalyst separation and recovery, low yield of product DMC, large amount of catalyst usage, etc., and achieve good catalyst reusability, The effect of mature production technology and convenient product purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

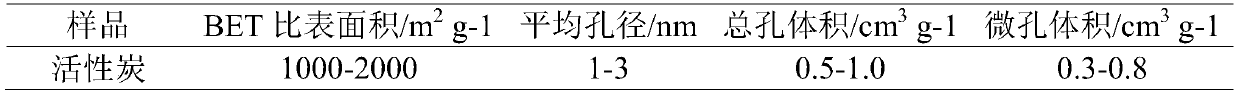

[0017] In a 100mL autoclave, add methanol 12mL (0.3mol), ethylene carbonate 2.64g (0.03mol), activated carbon (0.26g), and use CO 2 Replace the air in the autoclave twice, and then fill with CO 2 to 0.5Mpa, magnetically stirred and heated, the temperature was raised to 100°C, and the reaction was carried out at this temperature for 6h. After cooling down to room temperature, the reaction solution was centrifuged and analyzed. The conversion rate of ethylene carbonate is 65%, and the selectivity of dimethyl carbonate is 98%.

Embodiment 2

[0019] In a 100mL autoclave, add methanol 12mL (0.3mol), ethylene carbonate 2.64g (0.03mol), activated carbon (0.52g), and use CO 2 Replace the air in the autoclave twice, and then fill with CO 2 to 0.3Mpa, magnetically stirred and heated, the temperature was raised to 160°C, and the reaction was carried out at this temperature for 8h. After cooling down to room temperature, the reaction solution was centrifuged and analyzed. The conversion rate of ethylene carbonate is 97%, and the selectivity of dimethyl carbonate is 99%.

Embodiment 3

[0021] In a 100mL autoclave, add methanol 12mL (0.3mol), ethylene carbonate 2.64g (0.03mol), activated carbon (0.40g), and use CO 2 Replace the air in the autoclave twice, and then fill with CO 2 to 2Mpa, magnetically stirred and heated, the temperature was raised to 140°C, and the reaction was carried out at this temperature for 4h. After cooling down to room temperature, the reaction solution was centrifuged and analyzed. The conversion rate of ethylene carbonate is 85%, and the selectivity of dimethyl carbonate is 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com