Method for extracting high-purity omega-3 polyunsaturated fatty acid phospholipids from shrimp head

A fatty acid phospholipid, high-purity technology, applied in the direction of chemical instruments and methods, edible phospholipid composition, compounds of group 5/15 elements of the periodic table, etc., can solve the problem of low yield and purity of phospholipids, affecting the quality of phospholipids, and robbing food Resources and other issues, to achieve the effect of wide and cheap raw material sources, reduced extraction costs, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

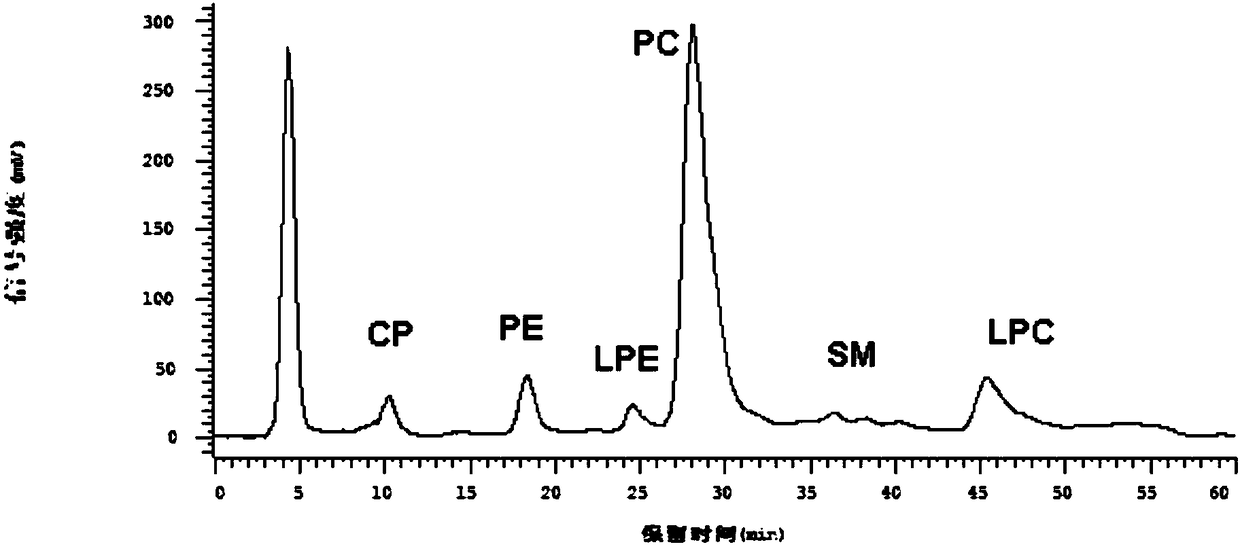

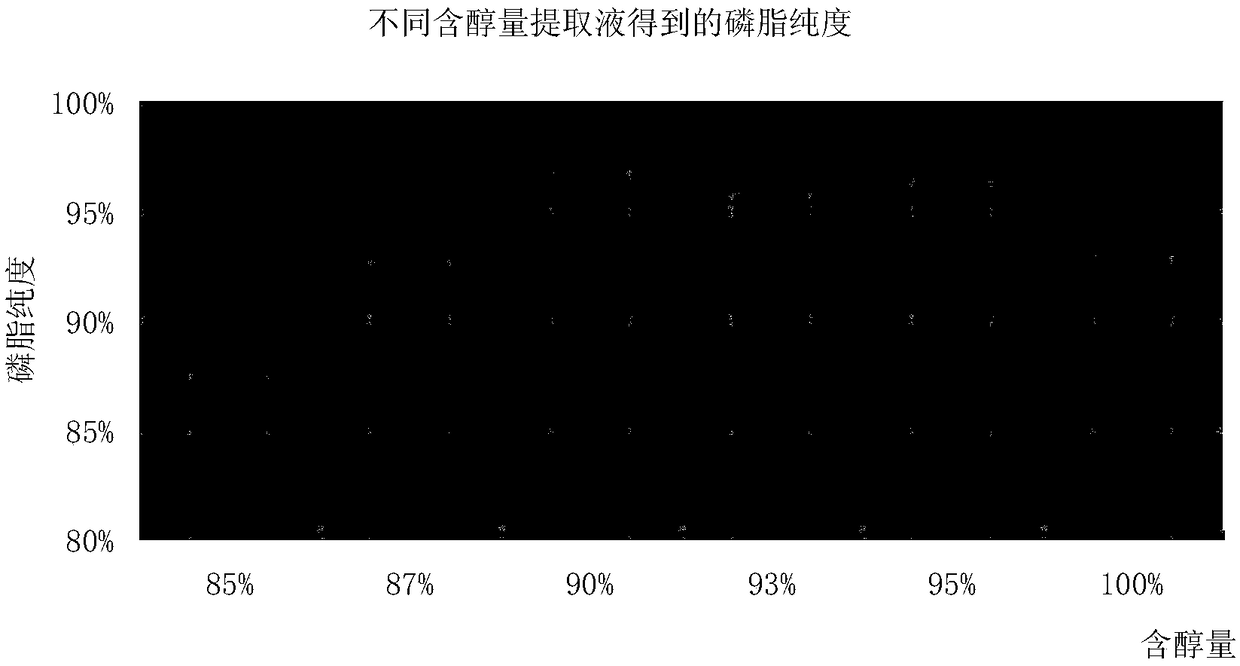

[0038] Weigh 100g of Chinese prawn heads frozen for 20 days, add 100mL of water, pulverize and homogenize for 18min, adjust the pH to 6.5 with acetic acid-sodium acetate buffer solution, heat to 40°C, add 0.2g of compound enzyme, and hydrolyze for about 2h; Centrifuge the enzymolysis solution, pass the solid part through 1000mL 93% ethanol solution (adjust the pH to 9.0 with sodium acetate), ultrasonically extract twice at 34°C, 30min each time, and the ultrasonic frequency is 31KHz, combine the extracts, and filter under reduced pressure , the filtrate was concentrated under reduced pressure at 45°C to obtain crude phospholipids; a small amount of dichloromethane dissolved the crude phospholipids, and after filtration, the filtrate was placed on Bio-Beads S-X 3 Chromatographic column, after cyclohexane elution removes small polar impurities, cyclohexane-ethyl acetate isocratic elution in a ratio of 1:1, the flow rate is 1.0 times the column volume per hour, and is detected by ...

Embodiment 2

[0041] Weigh 100g of fresh vannamei shrimp head, add 150mL of water, pulverize and homogenize for 12min, adjust the pH to 6.5 with acetic acid-sodium acetate buffer solution, heat to 45°C, add 0.4g of compound enzyme, and hydrolyze for about 2h; After centrifugation, the solid part was subjected to 1200mL of 95% ethanol (sodium bicarbonate to adjust its pH to 9.0), ultrasonically extracted twice at 35°C, each time for 15min, and the ultrasonic frequency was 34KHz, the extracts were combined, and after vacuum filtration, the filtrate was Concentrate under reduced pressure at 45°C to obtain crude phospholipids; dissolve the crude phospholipids in a small amount of dichloromethane, filter, and put the filtrate on Bio-Beads S-X 3 Chromatographic column, after cyclohexane elution removes small polar impurities, cyclohexane-ethyl acetate is eluted in a ratio of 3:2, the flow rate is 0.5 times the column volume per hour, and is detected by thin layer chromatography. Dichloromethane-a...

Embodiment 3

[0043] Weigh 100g of fresh Penaeus monodon shrimp head, add 120mL of water, pulverize and homogenize for 8 minutes, adjust the pH to 6.5 with acetic acid-sodium acetate buffer solution, heat to 43°C, add 0.6g of compound enzyme, and hydrolyze for about 1.5h; Solid-liquid separation, the solid part was extracted with 600mL of 90% ethanol (sodium bicarbonate to adjust its pH to 10.0), ultrasonically extracted twice at 32°C, each time for 20min, and the ultrasonic frequency was 32KHz, the combined extracts were filtered under reduced pressure , the filtrate was concentrated under reduced pressure at 43°C to obtain crude phospholipids; a small amount of dichloromethane dissolved the crude phospholipids, and after filtration, the filtrate was placed on Bio-Beads S-X 3 Chromatographic column, after cyclohexane elution removes small polar impurities, cyclohexane-ethyl acetate is eluted at a ratio of 2:1, the flow rate is 1.5 times the column volume per hour, and is detected by thin-la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com