Method for preparing composite wood and composite wood

A composite material and polymer technology, which can be used in the field of preparing composite materials with light stability, and can solve the problems of light stability of polymer products and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

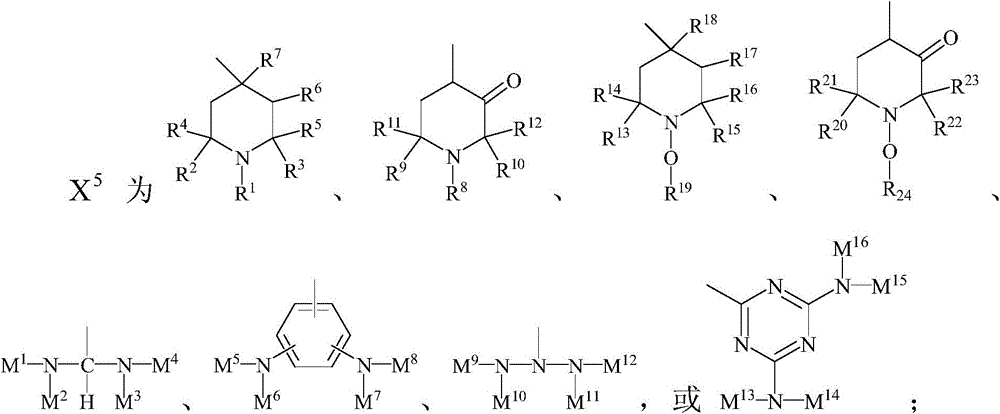

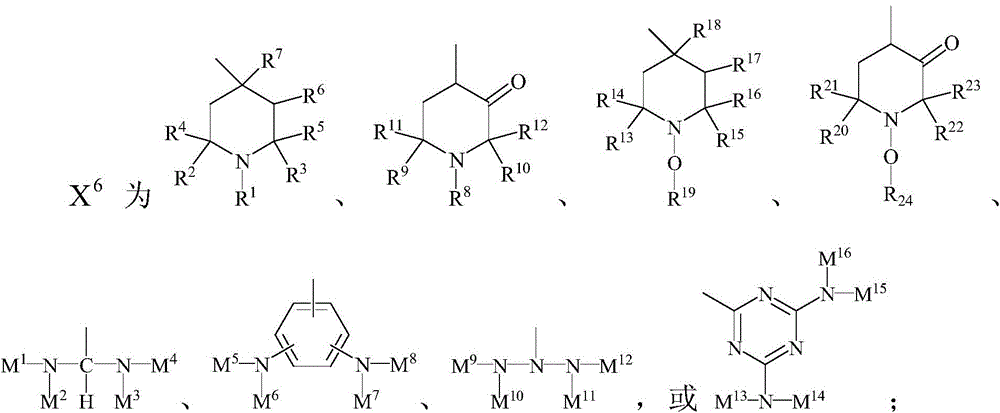

Method used

Image

Examples

Embodiment 1

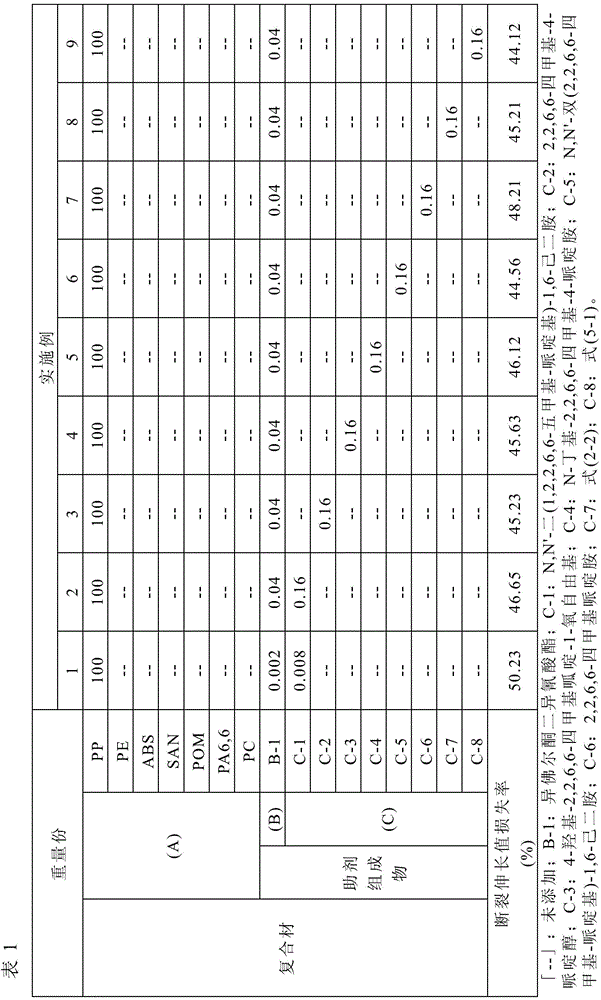

[0080] Embodiment 1 Composite material

[0081] 0.002 parts by weight of isophorone diisocyanate, 0.008 parts by weight of N,N'-bis(1,2,2,6,6-pentamethyl-piperidinyl)-1,6-hexanediamine, and 100 parts by weight of PP were mixed evenly, and extruded by a twin-screw extruder, the extrusion temperature was 180° C., and the rotational speed of the main screw was 100 rpm.

Embodiment 2 to 9

[0083] Examples 2 to 9 prepared the composite material in the same steps as in Example 1, except that the types and amounts of raw materials were changed. The kind and usage amount of this raw material are shown in Table 1.

Embodiment 10

[0085] 4 parts by weight of isophorone diisocyanate, 16 parts by weight of N,N'-bis(1,2,2,6,6-pentamethyl-piperidinyl)-1,6-hexanediamine, and 80 parts by weight of PP were mixed uniformly and extruded by a twin-screw extruder at an extrusion temperature of 180° C. and a main screw rotating speed of 100 rpm to form an extruded product. The extrudate will be cooled by air at room temperature, pelletized at 60 rpm, and dried at 100°C for 4 hours to form a dry product. Mix 1 part by weight of the dried material and 100 parts by weight of PP uniformly, and extrude with a twin-screw extruder, the extrusion temperature is 180° C., and the rotational speed of the main screw is 100 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com